Greensmaster 3250--DHydraulic System Page 4 -- 68

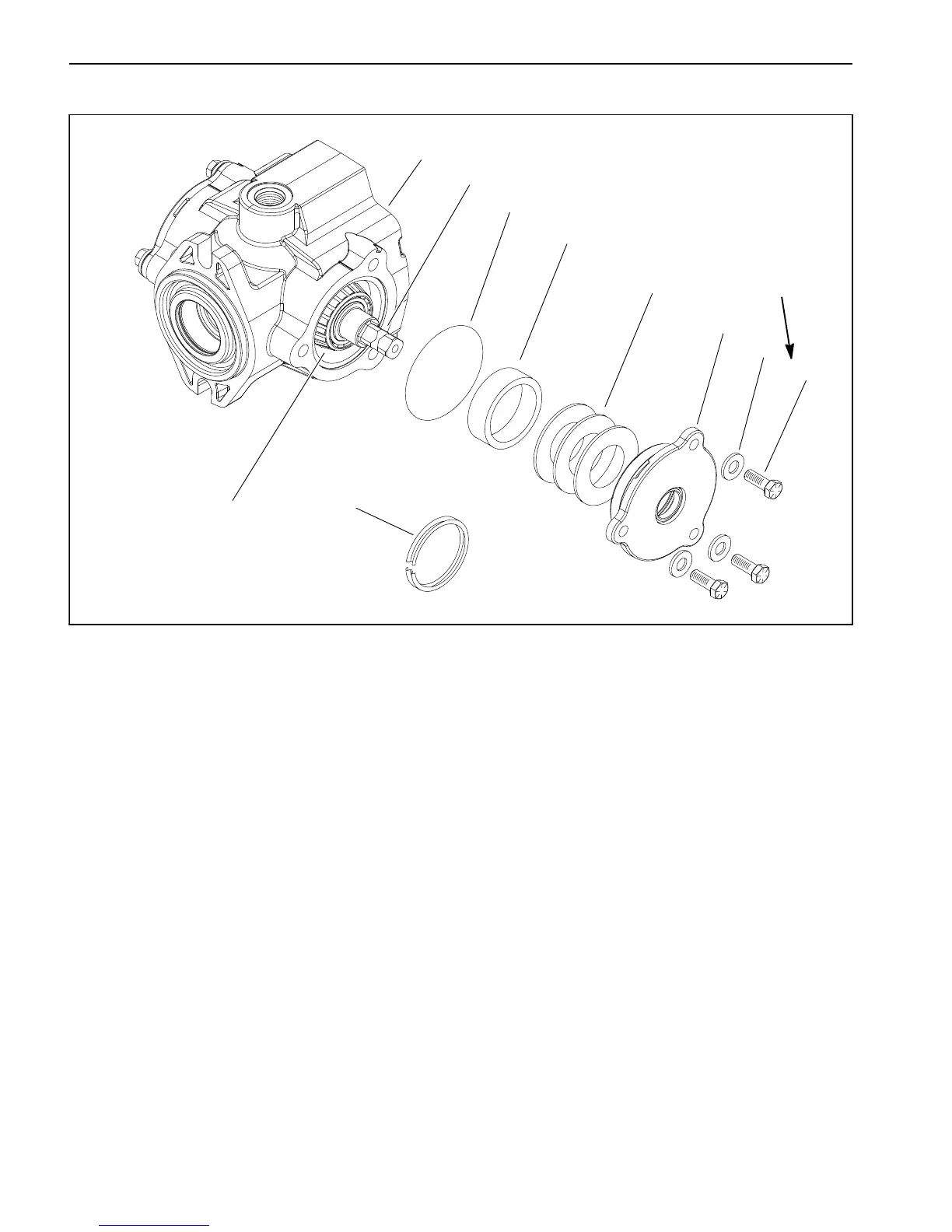

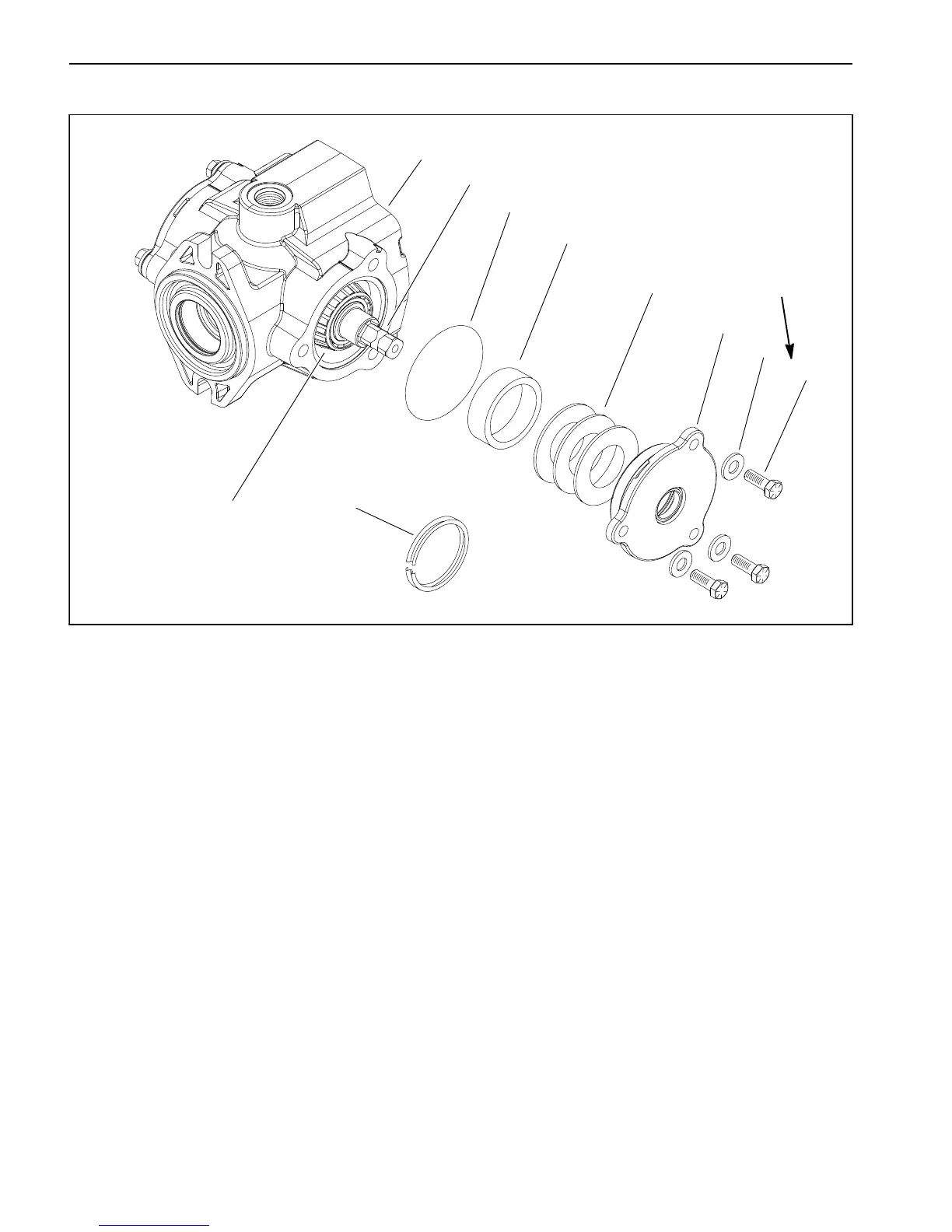

Piston Pump Crush Ring Replacement

1. Crush ring

2. Shims

3. Cover plate

4. Housing

5. Swash plate (control shaft)

6. Bearing cone

7. Bearing cup

8. O--ring

9. Washer (3 used)

10. Cap screws (3 used)

Figure 46

29 ft--lb

(39 N--m)

6

4

8

7

2

3

9

10

1

5

NOTE: The shims replace the crush ring in the cover

plate.Ifthecamplate,coverplateorhousingisreplaced

during servicing of the pump, the old crush ring can not

be used to make sure of proper preload.

1. Remove crush ring from the cov er plate. Measure

thickness of crush ring.

2. Stack shims to the thickness of the crush ring.

3. Insert shims intothecoverplateinthe same location

that the crush ring was removed from.

4. Assemble housing sub assembly consisting of the

housing, camplate, bearing cone, bearing cup and cov-

er plate (see Eaton, Medium Duty Piston Pump, Repair

Information,Model70160VariableDisplacementPiston

Pump at the end of this chapter).

5. Install washers and cap screws to the cover plate

and housing.Torquecap screws to 29 ft--lbs (39 N--m).

6. Checktorquerequiredto rotatecontrolshaft.Torque

should be 5to15in--lbs(0.6to1.7N--m).

A. If torque is too low, add additional shims and re-

peat steps 3 through 6 until the specified torque is

achieved.

B. If torque is too high, remove shims and repeat

steps 3 through 6 until the specified torque is

achieved.

7. Complete assembly of thepump(seeEaton,Me-

dium Duty Piston Pump, Repair Information, Model

70160VariableDisplacementPistonPumpattheendof

this chapter).

Loading...

Loading...