Greensmaster 3250--D

DPA Cutting Units

Page 7 -- 21

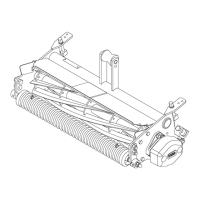

Reel Assembly Removal (Fig. 21)

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when removing the cutting reel.

1. Positionmachineonacleanandlevelsurface,lower

cuttingunits,stopengine,engageparkingbrakeandre-

move key from the ignition switch.

2. Remove the cutting unitfromthemachine and place

cutting unit on a flat work area.

3. Ifcuttingunitisequippedwithanoptionalgroomeror

rear roller brush, remove drive components for those

options from cutting unit. See Service and Repairs sec-

tionofChapter8 -- Groomerforinformation ongroomer.

See R ear Roller Brush in this section for information on

rear roller brush.

4. Remove two (2) cap screws and nuts that secure

weight (item 10) to the side plate. Remove weight from

the cutting unit. Remove and discard O--ring from

weight.

NOTE: The reel nut on the left end of the cutting reel

hasablackfinishandhasLHthreads.Theleftendofthe

cuttingreelshaftisidentifiedwithagroovethatisjustin-

side of the reel spider (Fig. 22).

5. If bearings or seals are to be removed from cutting

reel,putablockofwoodbetweenthecuttingreelblades

to prevent the reel from rotating. Loosen reel nuts to al-

loweasierremovalafterreelassemblyis removed from

cutting unit (Fig. 22).

6. Remove the bedbar pivot bolt and washers from the

LHsideplate.Notelocationofplasticandsteelwashers

for assembly purposes (see Bedbar Removal in this

section).

7. Loosenfastenersthatsecurefrontandrearrollersto

LHsideplate(seeFrontRollerRemovalandRearRoller

Removal in this section).

8. Support cutting reel to prevent it from shifting or fal-

ling.

9. Removeshoulderbolts(item4)andflangenuts(item

5)thatsecuretheLHsideplateto the cutting unit cross-

member. Remove the LH side plate from the reel shaft,

rollers, bedbar and cutting unit crossmember.

10.Carefully slide the cutting reel assembly (with

flocked seals, reel bearings and reel nuts) from the RH

side plate.

1. Cutting reel

2. Flocked seal (2 used)

3. Bearing (2 used)

4. Plug (2 used)

5. Bearing lock screw

6. Reel nut (LH threads)

7. Reel groove location

Figure 22

1

2

3

4

5

3

2

7

6

(Right Hand Threads)

90 to 110 ft--lb

(123 to 149 N--m)

90 to 110 ft--lb

(123 to 149 N--m)

(Left Hand Threads)

Reel Assembly Installation (Fig. 21)

1. Thoroughly clean side plates and other cutting unit

components. Inspect side plates for wear or damage

and replace components if needed.

2. Make sure that flocked seals, reel bearings and reel

nuts are properly positioned on cutting reel (see Reel

Assembly Service in this section). Apply thin coat of

greasetooutsideofbearingsoncuttingreeltoeasereel

installation.

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when installing the cutting reel.

3. Position the cutting unit on a flat work area. The roll-

ers,bedbarandcuttingunitcrossmembershouldbeat-

tached to RH side plate.

4. Carefully slide the cutting reel assembly (with

flocked seals, reel bearings and reel nuts) into the RH

side plate. Make sure that bearing is fully seated into

side plate.

5. Place flat wire spring into bearing bore of LH side

plate. Carefully slide the LH side plate onto the cutting

reelassembly,frontrollerandrearroller.Makesurethat

side plate is fully seated onto bearing on reel shaft.

DPA Cutting

Units

Loading...

Loading...