Greensmaster 3250--D Hydraulic SystemPage 4 -- 3 1

Procedure for Charge Relief Valve Pressure

Test

The tractionchargecircuit is designedtoreplacelossof

hydraulic fluid from the closedlooptractioncircuit.The

charge relief valve pressure test will identify if charge

pressure is correct.

1. Make sure hydraulic oil is at normal operating tem-

peraturebyoperatingthemachineforapproximatelyten

(10) minutes.

2. Parkmachineonalevelsurfacewiththecuttingunits

lowered. Make sure engine is off and the parking brake

is engaged. Make sure the hydraulic tank is full.

CAUTION

Before continuing further, read and become fa-

miliar with Precautions for Hydraulic Testing.

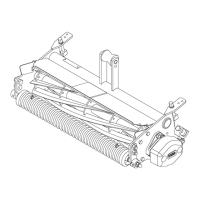

3. Install 1000 PSI (70 bar) pressure gauge with hy-

draulic hose attached to test port in the tee fitting on the

bottom of the control manifold (Fig. 18).

4. Make sure that traction pedal, steering wheel and

joystick are in the neutral position.

5. Start engine and run at low idle speed. Check for hy-

draulic leakage at pressure gauge and correct before

proceeding with test.

6. Move throttle so engine is runningat high idlespeed

(2710 +

50 RPM).

7. Pressure gauge should read approximately 100 to

150PSI(7to10bar).

8. Shut off engine. Record test results.

9. If specification is not met, remove piston pump back

plateassemblythatcontainsthechargereliefvalve(see

Piston (Traction) Pump Service in the Service and Re-

pairs section of this chapter). Repair or replace relief

valve components as necessary.

10.Adynamicchargepressuretestcanbeperformedas

follows:

A. Position machine so that a load can be placed on

thetractionsystem.For example, chainthemachine

to an immovable object or chock all drive wheels to

prevent the machine from moving.

B. Withpressuregaugestillconnected,sitintheop-

eratorseat,startthe engine and movet hrottle so en-

gine is running at high idle speed. Move functional

control lever to the transport position.

C. While monitoring the pressure gauge, push the

tractionpedalintheappropriatedirection(forwardor

reverse) to allow traction system load.

D.Thechargepressureshoulddropnomorethan

20% from no--load charge pressure measured in

step 7 above (e.g. if charge pressure in step 8 is125

PSI (9 bar), charge pressure in forward or reverse

under load should be more than 100 PSI (7 bar)).

E. If charge pressure is good under no load, but

drops below specification when under traction load,

the piston (traction) pump and/or wheel motors

should be suspected of wear and inefficiency. When

thepumpand/ortractionmotor(s)arewornordam-

aged,thechargepumpisnotableto keepupwithin-

ternalleakageintractioncircuitcomponents.Further

testing of the traction circuit should be completed

(see Piston (Traction) Pump Flow and Wheel Motor

Efficiency Tests in this section).

11.Whenchargepressuretesting is complete, discon-

nect pressure gauge from the test port and install dust

cap.

Figure 18

FRONT

1

2

1. Control manifold 2. Test port

Hydraulic

System

Loading...

Loading...