Greensmaster 3250--D Hydraulic SystemPage 4 -- 7 9

IMPORTANT: Mark therelativepositions of the gear

teeth and the bearing blocks so they can be re-

assembled in the same position. Do not touch the

gearsurfacesasresidueonhandsmaybecorrosive

to gear finish.

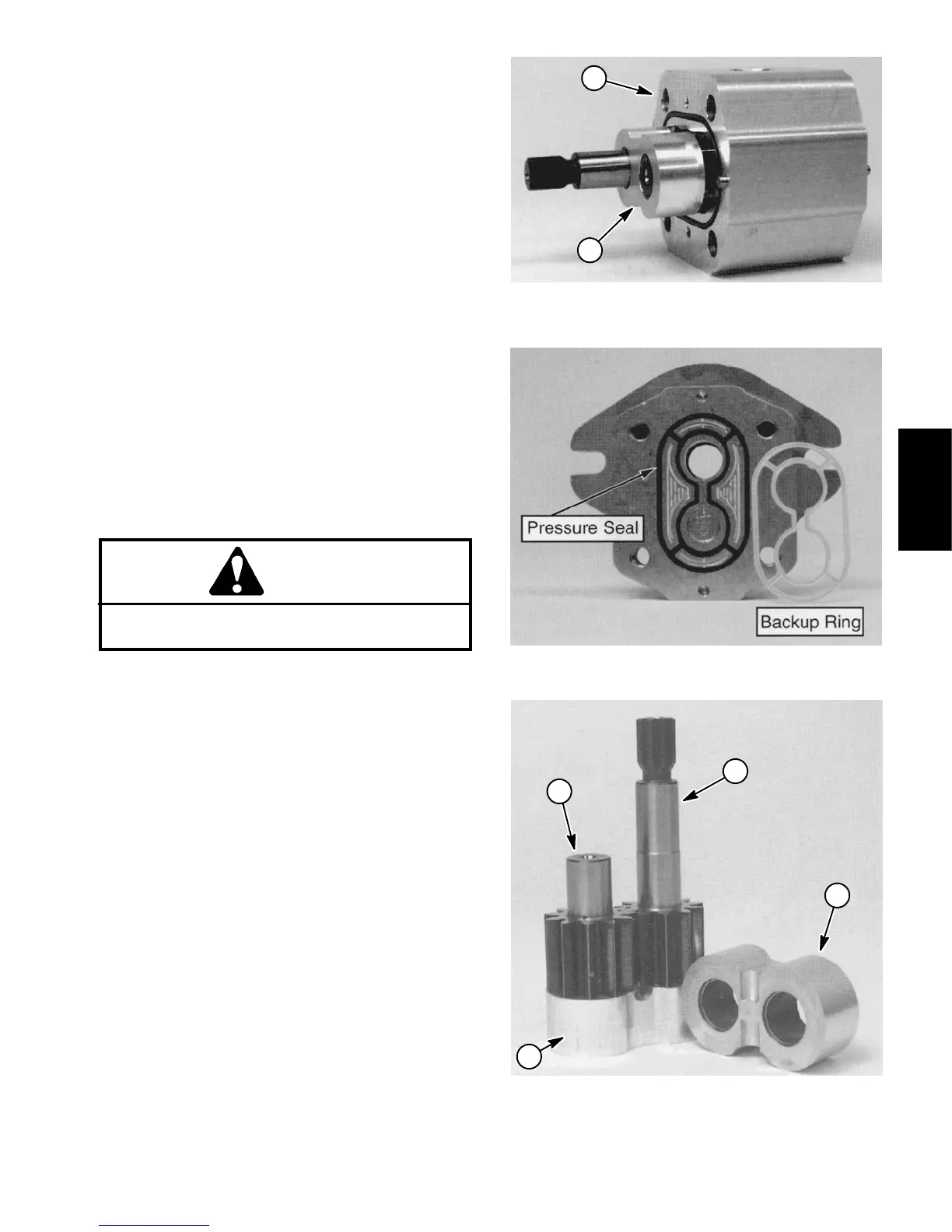

7. Placethemotoronitssideandpushontherearbear-

ingblock to remove the bearingblockandgearset(Fig.

54).

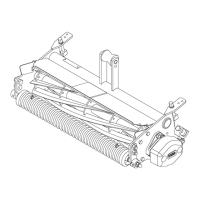

8. Carefully remove and discard O--r ings, pressure

seals and back--up rings (Fig. 55) from motor. Do not

cause any damage to the machined grooves during the

removal process.

IMPORTANT: Make sure not to damage the counter

bore when removing the shaft seal from the front

plate.

9. Positionfrontflangewith sealsideup.Remove shaft

seal.

Inspection

1. Remove any nicks and burrs from all motor compo-

nents with emery cloth.

CAUTION

Use eye protection such as goggles when using

compressed air.

2. Clean all motor components with solvent. Dry all

parts with compressed air.

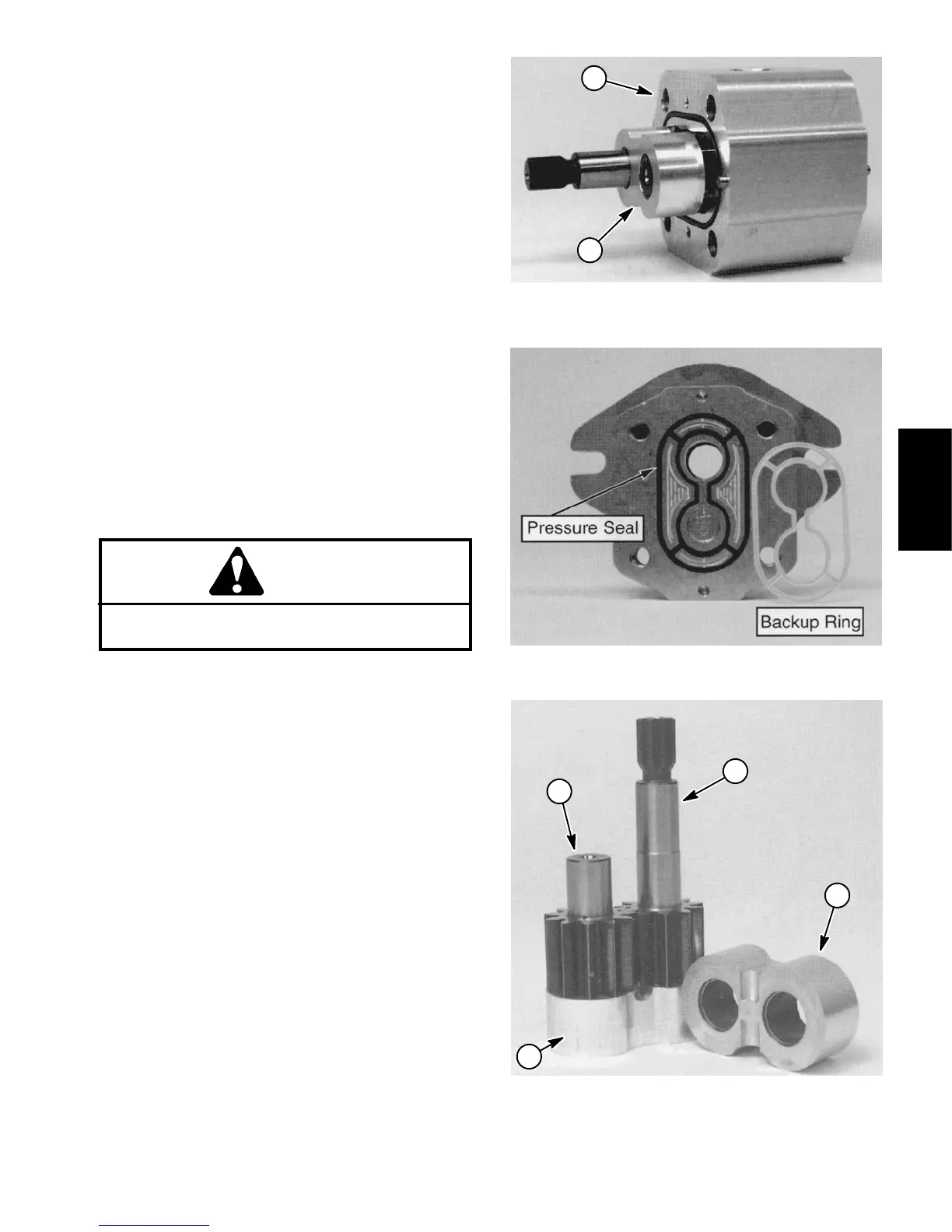

3. Inspect drive gear, idler gear and bearing blocks

(Fig. 56) for the following:

A. Gear shafts shouldbefree of rough surfacesand

excessivewear at bushing pointsand sealing areas.

Scoring, rough surfaces or wear on gear shafts indi-

cates need for replacement.

B. Gear teeth should be free of excessive scoring

and wear. Any broken or nicked gear teeth must be

replaced.

C. Inspect gear face edge for sharpness. Sharp

edgesof gearswill millintobearingblocksand,thus,

must be replaced.

D. Bearing areas of bearing blocks should not have

excessive wear or scoring.

E. Face of bearing blocks that are in contact with

gears should be f ree of wear, roughness or scoring.

4. Inspect front flange and rear cover for damage or

wear.

1. Motor body 2. Bearing block & gear set

Figure 54

2

1

Figure 55

1. Drive gear

2. Idler gear

3. Bearing block

Figure 56

2

1

3

3

Hydraulic

System

Loading...

Loading...