Greensmaster 3250--D Hydraulic SystemPage 4 -- 5 9

6. Support the pump assembly and gently tap the

pump housing with a soft face hammer to loosen the

pump sections. Be careful to not drop parts or disen-

gage gear mesh.

IMPORTANT: Mark therelativepositions of the gear

teeth and the thrust plates so they can be as-

sembledinthesameposition. Donottouchthegear

surfaces as residue on hands may be corrosive to

gear finish.

7. Remove thethrustplatesand seals fromeachpump

section. Before removing each gear set, apply marking

dye to mating teeth to retain ”timing”. Pump efficiency

maybeaffectediftheteetharenotinstalled in the same

positiond uring assembly.Keeptheparts foreachpump

section together; do not mix parts between sections.

8. Clean all parts. Check all components for burrs,

scoring, nicks and other damage.

9. Replacetheentirepumpassemblyifanypumpcom-

ponents are excessively worn or scored.

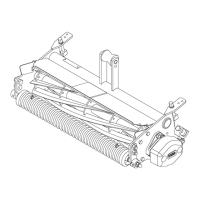

Gear Pump Assembly (Fig. 35)

1. Apply clean hydraulic oil to all parts before assem-

bling.

NOTE: Pressure and back--up seals fit in grooves ma-

chinedintothrustplates.BodyO--ringsfitingroovesm a-

chined in housing.

2. Assemble pump sectionsstarting at front cover end.

Apply grease or petroleum jelly to new section seals to

hold them in position during gear pump assembly.

3. After pump has been assembled, tighten socket

headscrewsbyhand.Rotatethedriveshafttocheckfor

binding.Protecttheshaft if using a pliersto rotateshaft.

4. Tighten the socket headscrews evenly in a crossing

patterntoatorqueof33 ft--lb (45 N--m).

Hydraulic

System

Loading...

Loading...