134

OHA088B

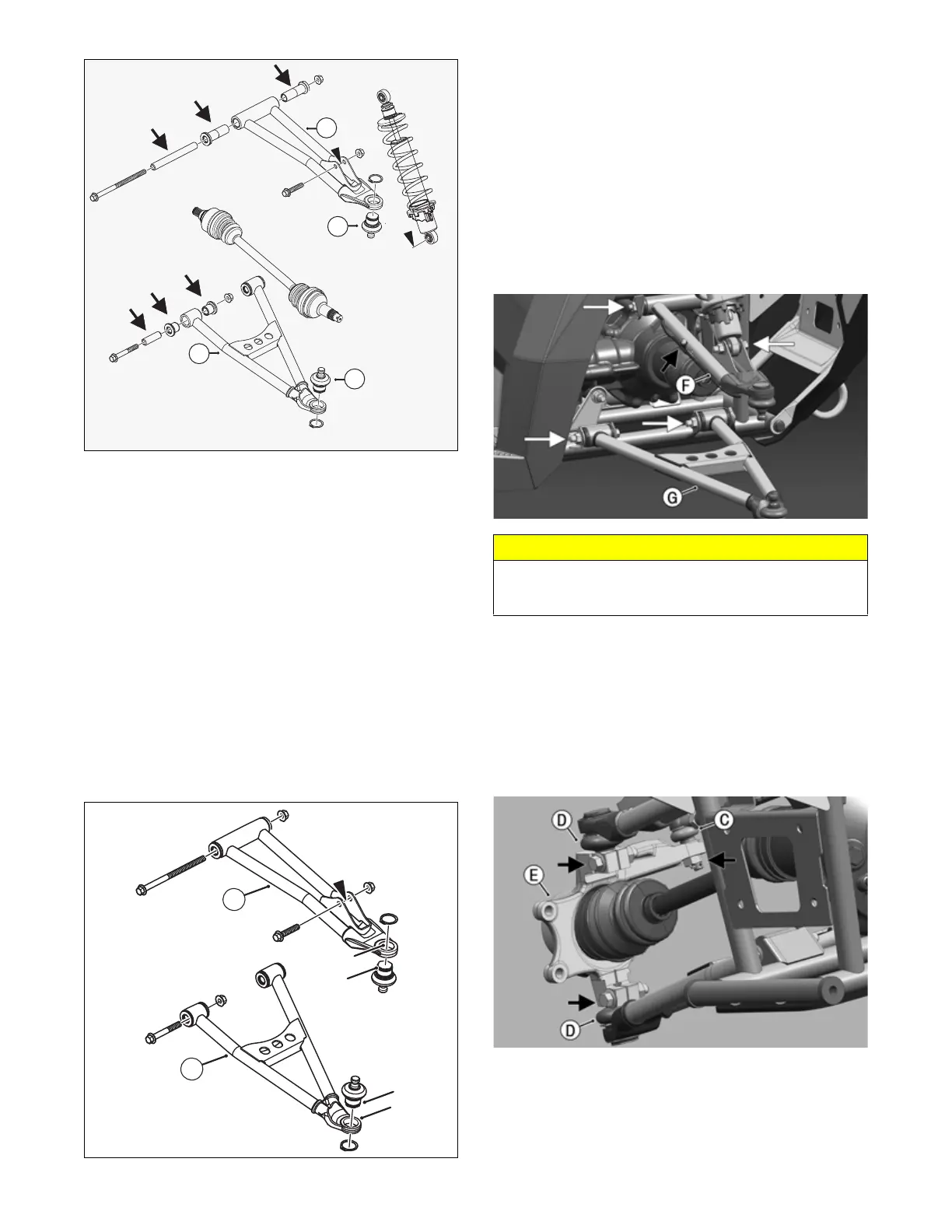

CLEANING AND INSPECTING

1. Clean all A-arm components using a pressure

washer.

2. Clean the ball joint mounting hole of all residual

Loctite, grease, oil, or dirt for installing purposes.

3. Inspect the A-arm for bends, cracks, and worn bushings.

4. Inspect the ball joint mounting holes for cracks or

damage.

5. Inspect the frame mounts for signs of damage, wear,

or weldment damage.

INSTALLING

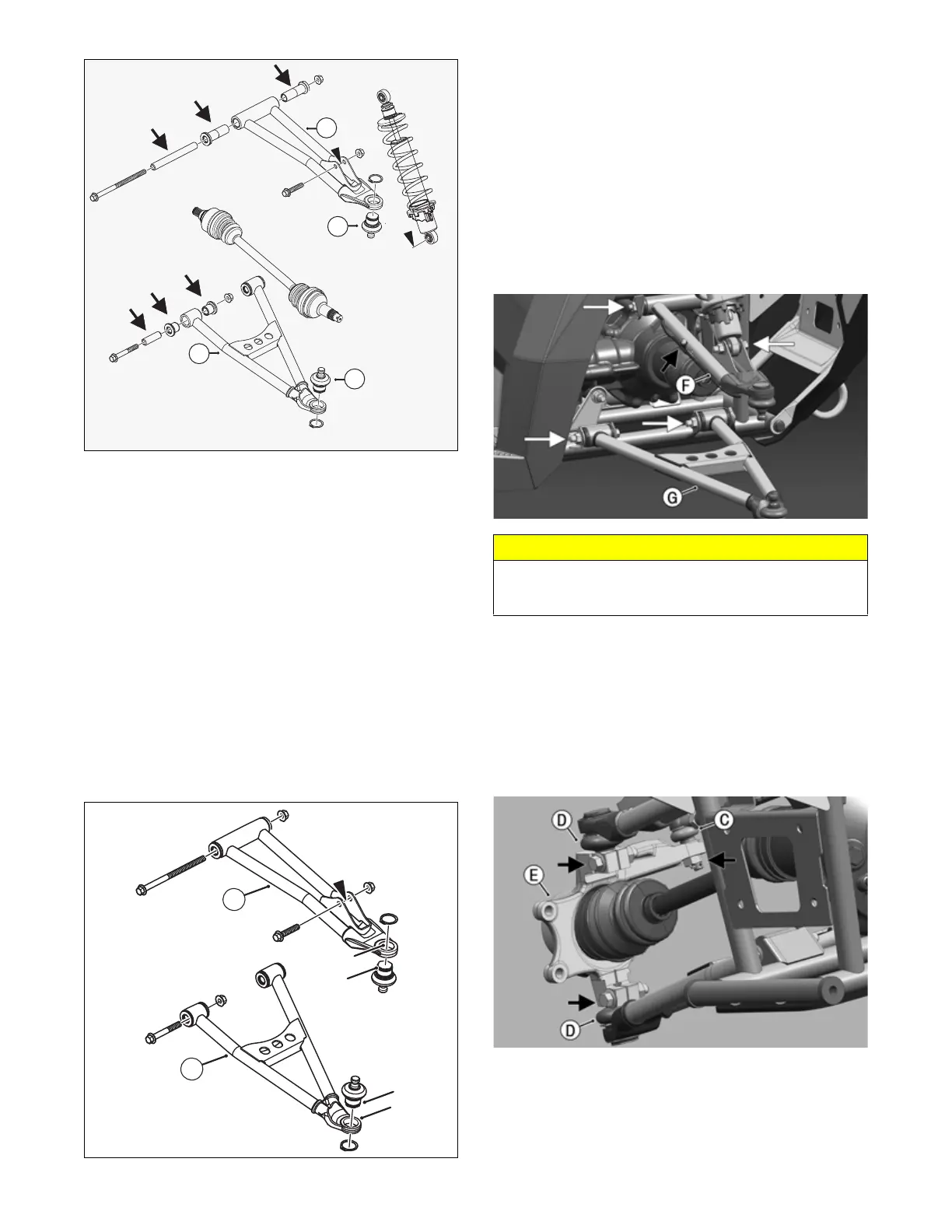

1. Apply Loctite Primer “T” to the arm socket; then

apply green Loctite 609 to the entire outside diame-

ter of the ball joint (D). Install the ball joint into the

A-arm and secure with the snap ring.

OHA091

2. Install the upper (F) and lower (G) A-arm assemblies

into the frame mounts and secure with the cap

screws. Only finger-tighten at this time.

3. Reattach brake hose clamp to upper A-arm (F).

NOTE: Do not allow the brake caliper to hang from

the cable/hose.

4. Secure the lower eyelet of the shock absorber to the

upper A-arm (F). Tighten nut to 42 ft-lb (56.9 N-m).

5. Secure the A-arm assemblies to the frame mounts

(from step 2). Tighten the cap screws to 42 ft-lb

(56.9 N-m).

OHA088A

6. Install the knuckle assembly (E) onto the ball joints

(D) and secure with cap screws. Tighten to 45 ft-lb

(61 N-m).

7. Install the tie rod end (C) and secure with the nut.

Tighten to 30 ft-lb (40.7 N-m); then install a new cot-

ter pin and spread the pin to secure the nut.

NOTE: During assembly, new cotter pins should be

installed.

OHA087

8. Apply grease to the hub and drive axle splines; then

install the hub assembly onto the drive axle.

CAUTION

Do not tighten the nut beyond the 42 ft-lb (56.9 N-m)

specification. The shock eyelet or mount WILL be dam-

aged.

Loading...

Loading...