69

3 If adjustment is needed, use driven clutch shims to

adjust:

0823-704 – 3 mm

0823-705 – 4 mm

0823-706 – 5 mm

0823-752 – 6 mm

0823-753 – 7 mm

OHA153

DRIVE BELT BREAK-IN

A new drive belt requires a break-in period of approxi-

mately 50 miles (80 km).

1. Drive the vehicle approximately 50 miles (80 km) at

3/4 throttle or less. If possible, vary the throttle posi-

tion during the break-in period, not exceeding 3/4

throttle.

2. Do not exceed 40 mph (64 km/h) during the break-in

period.

3. Avoid heavy cargo or towing loads during break-in

period. Use the Low transmission gear if towing.

NOTE: Proper break-in will allow the drive belt to

gain its optimum flexibility and will extend drive belt

life.

Fuel/Lubrication/Cooling

NOTE: It is recommended to use new gaskets, lock

nuts, and seals, and lubricate all internal components

when servicing the engine/transmission.

SPECIAL TOOLS

A number of special tools must be available to the techni-

cian when performing service procedures in this section.

Refer to the current Special Tools Catalog for the appro-

priate tool description.

NOTE: When indicated for use, each special tool

will be identified by its specific name, as shown in the

chart below, and capitalized.

NOTE: Special tools are available from the Service

Department.

TROUBLESHOOTING

1. Verify that the electric fuel pump is operating by lis-

tening for a “whirring” sound for several seconds

after the ignition switch is turned to the ON position.

If no sound can be heard, see Electrical System —

EFI Sensors/Components.

2. Check for a flashing DTC (Diagnostic Trouble Code)

on the LCD gauge. If a code is flashing, see EFI

Diagnostic System in Electrical System section.

3. Make sure there is sufficient clean and fresh regular

87 octane E10 fuel in the gas tank.

Throttle Body

REMOVING

1. Turn the ignition switch to the OFF position; then

remove the ignition switch key.

2. Remove the seat and right-hand side panel; then dis-

connect the battery.

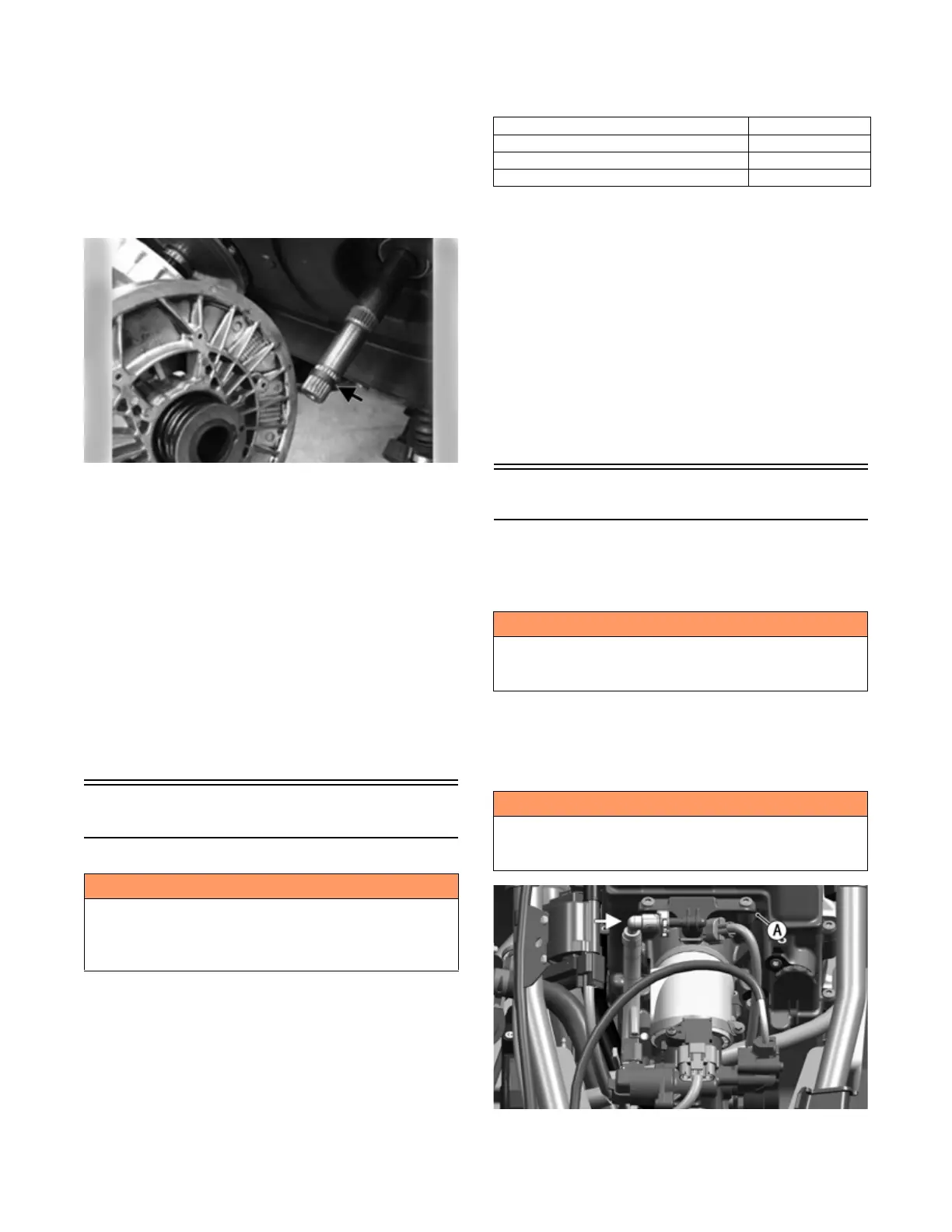

3. Slowly disconnect the gasline hose connector from

the fuel rail (A).

OHA076

4. Remove the screws securing the throttle actuator

cover (B) to the throttle body; then remove the cover.

! WARNING

Whenever any maintenance or inspection is performed

on the fuel system during which there may be fuel leak-

age, there should be no welding, smoking, open flames,

etc., in the area.

Description p/n

Oil Pressure Test Kit

0644-495

Seal Removal Tool

0644-072

Tachometer

Common Tool

! WARNING

Do not turn the ignition switch to the ON position with

the hoses removed. Gasoline will be pumped by the

electric fuel pump causing a safety hazard.

! WARNING

Gasoline may be under pressure. Place an absorbent

towel under the connector to absorb any gasoline spray

when disconnecting.

Loading...

Loading...