9

Testing Engine

Compression

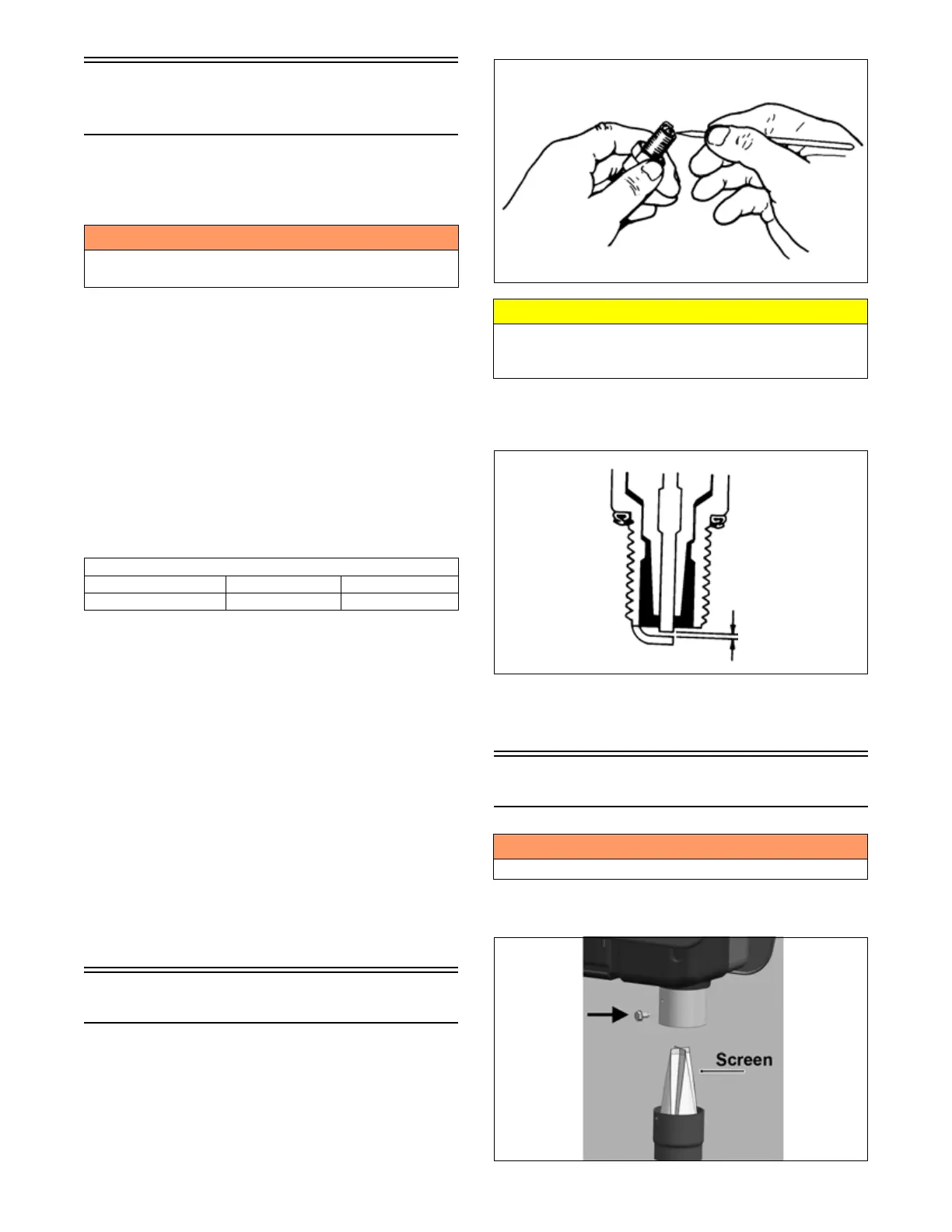

1. Remove the high tension lead from the spark plug.

2. Using compressed air, blow any debris from around

the spark plug.

3. Remove the spark plug; then attach the high tension

lead to the plug and ground the plug on the cylinder

head well away from the spark plug hole.

4. Attach the Compression Tester Kit.

NOTE: The engine should be warm (operating tem-

perature) and the battery fully charged for an accu-

rate compression test. Throttle must be in the

wide-open throttle (WOT) position. In the event the

engine cannot be run, cold values are included.

5. While holding the throttle lever in the full-open posi-

tion, crank the engine over with the electric starter

until the gauge shows a peak reading (five to 10

compression strokes).

6. If compression is abnormally low, inspect the

following items:

A. Verify starter cranks engine over at normal speed

(approximately 400 RPM).

B. Gauge functioning properly.

C. Throttle lever in the full-open position.

D. Valve/tappet clearance correct.

E. Engine warmed up.

F. Intake not restricted.

NOTE: To service valves, see Engine/Transmission.

7. Pour 29.5 mL (1 fl oz) of oil into the spark plug hole,

reattach the gauge, and retest compression.

8. If compression is now evident, service the top end

(see Engine/Transmission).

Spark Plug

A light brown insulator indicates that a plug and the

fuel/air ratio are correct. A white or dark insulator indi-

cates that the engine may need to be serviced. To main-

tain a hot, strong spark, keep the plug free of carbon.

ATV-0051

Adjust the gap to correct specification (see General Infor-

mation/Foreword — Specifications for proper type and

gap). Use a feeler gauge to check the gap.

ATV0052

A new spark plug should be tightened 1/2-turn once the washer

contacts the cylinder head. A used spark plug should be tight-

ened 1/8-1/4 turn once the washer contacts the cylinder head.

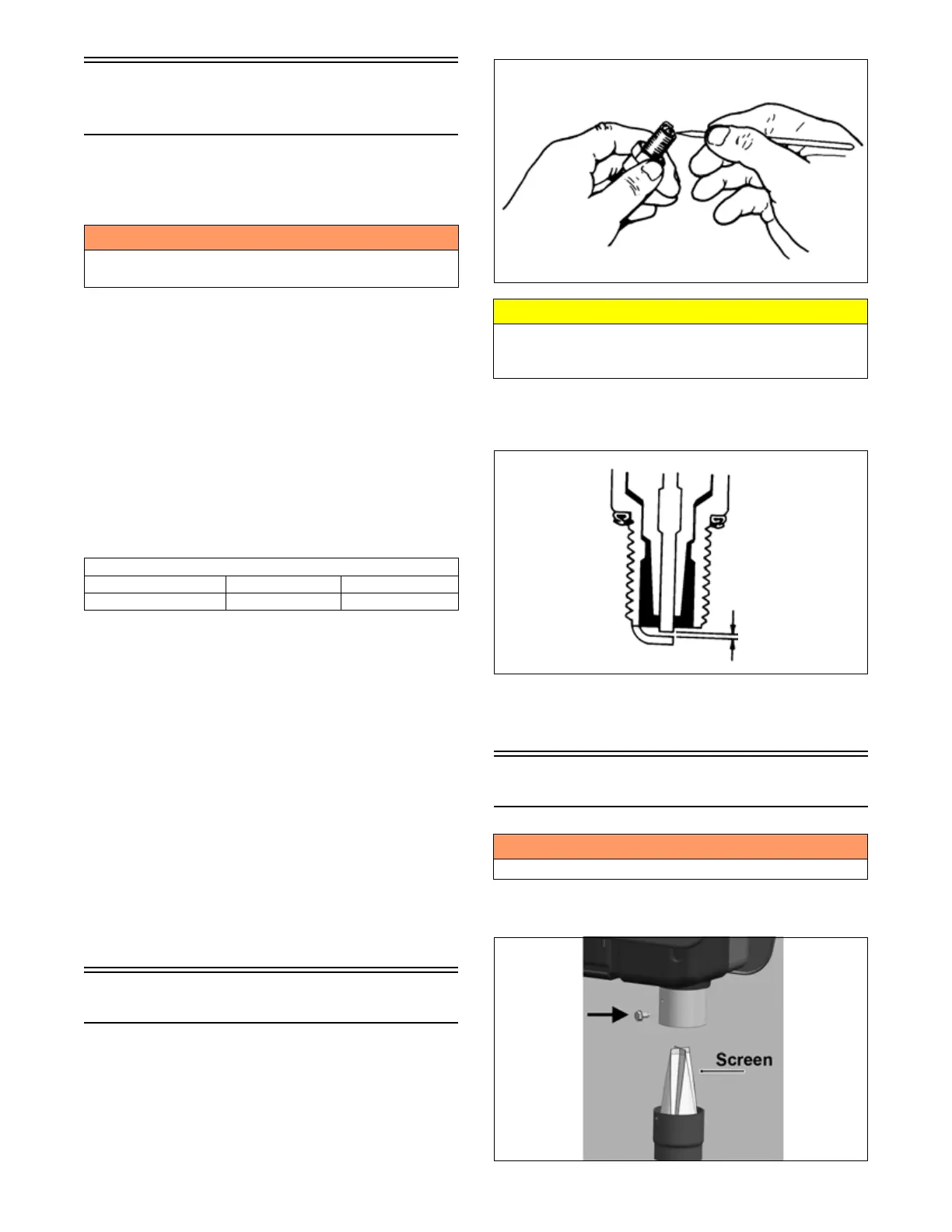

Muffler/Spark Arrester

1. Remove the cap screws securing the spark arrester

assembly to the muffler.

OHA034

! WARNING

Always wear safety glasses when using compressed

air.

COMPRESSION

Model PSI Hot (WOT) PSI Cold (WOT)

600

CAUTION

Before removing a spark plug, be sure to clean the area

around the spark plug. Dirt could enter engine when

removing or installing the spark plug.

! WARNING

Wait until the muffler cools to avoid burns.

Loading...

Loading...