36

Disassembling Engine

1. With the engine secured to a suitable engine stand,

drain oil, and remove oil filter, water pump, and hose

(see Fuel/Lubrication/Cooling section and see Starter

Motor sub-section in Electrical System section).

NOTE: Gear from water pump can be accessed

when upper oil pan is disassembled.

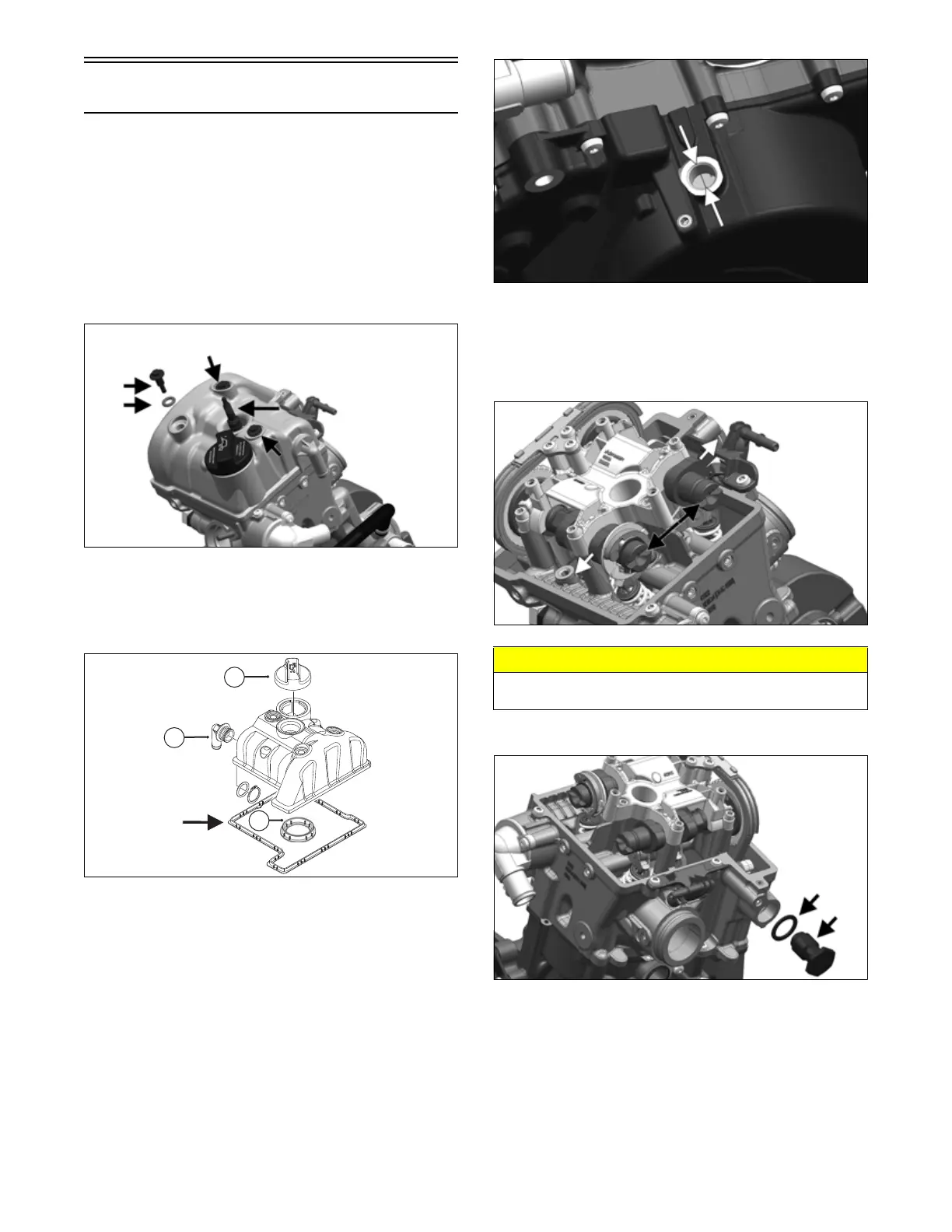

2. Remove the spark plug with a spark plug removal

tool. Then remove three bolts holding cylinder head

cover. Discard O-ring.

LYC001

3. Remove the cylinder head cover. Account for the

gasket. Remove fitting (A) if needed by removing

circlip. Account for O-ring. Oil cap (B) and valve

cover gasket (C) may also be removed.

LYC002

4. Rotate crankshaft in the direction of engine opera-

tion to the top dead center (TDC) position. Verify

TDC by removing the inspection cap from mag-

neto cover. Align magneto rotor so timing mark is

centered in inspection hole.

NOTE: If there is reason to suspect the engine is not

at TDC, perform a secondary check of TDC through

the spark plug hole.

NOTE: Remove magneto cover to determine the

cause of a misaligned timing mark.

LYC034

5. Position cam lobes facing away from each other

when slots are in line.

NOTE: A 6mm Allen wrench or bar placed between

both camshaft slots will ensure slots are in line.

LYC035

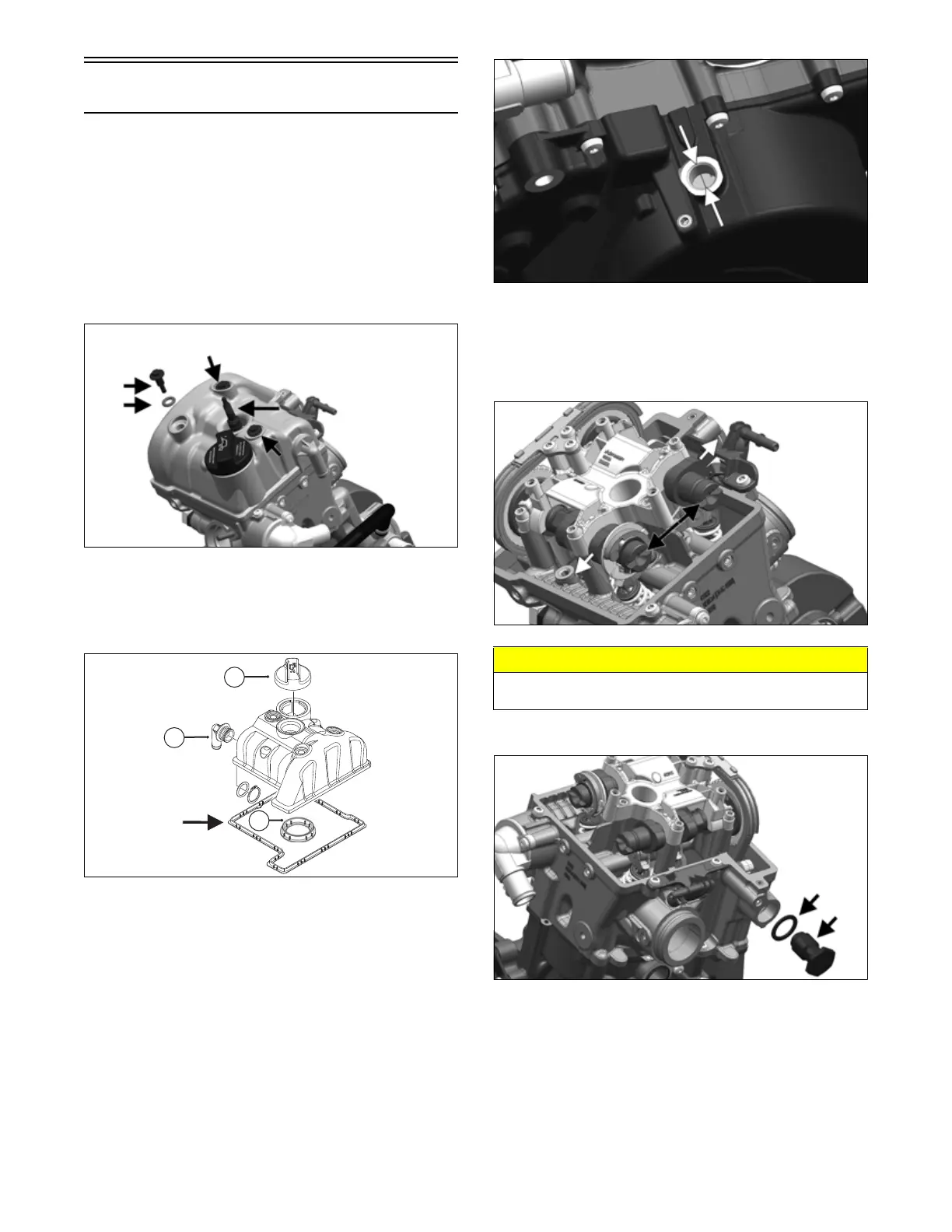

6. Remove chain tensioner and account for seal.

LYC036

7. Remove seven screws holding the cam bridge to cyl-

inder head using a crisscross sequence and remove

cam bridge (A). Account for O-ring. Chain guard

does not have to be removed from cam bridge unless

replacing either part.

CAUTION

Failure to perform timing steps could result in piston

damage.

Loading...

Loading...