59

Installing Engine

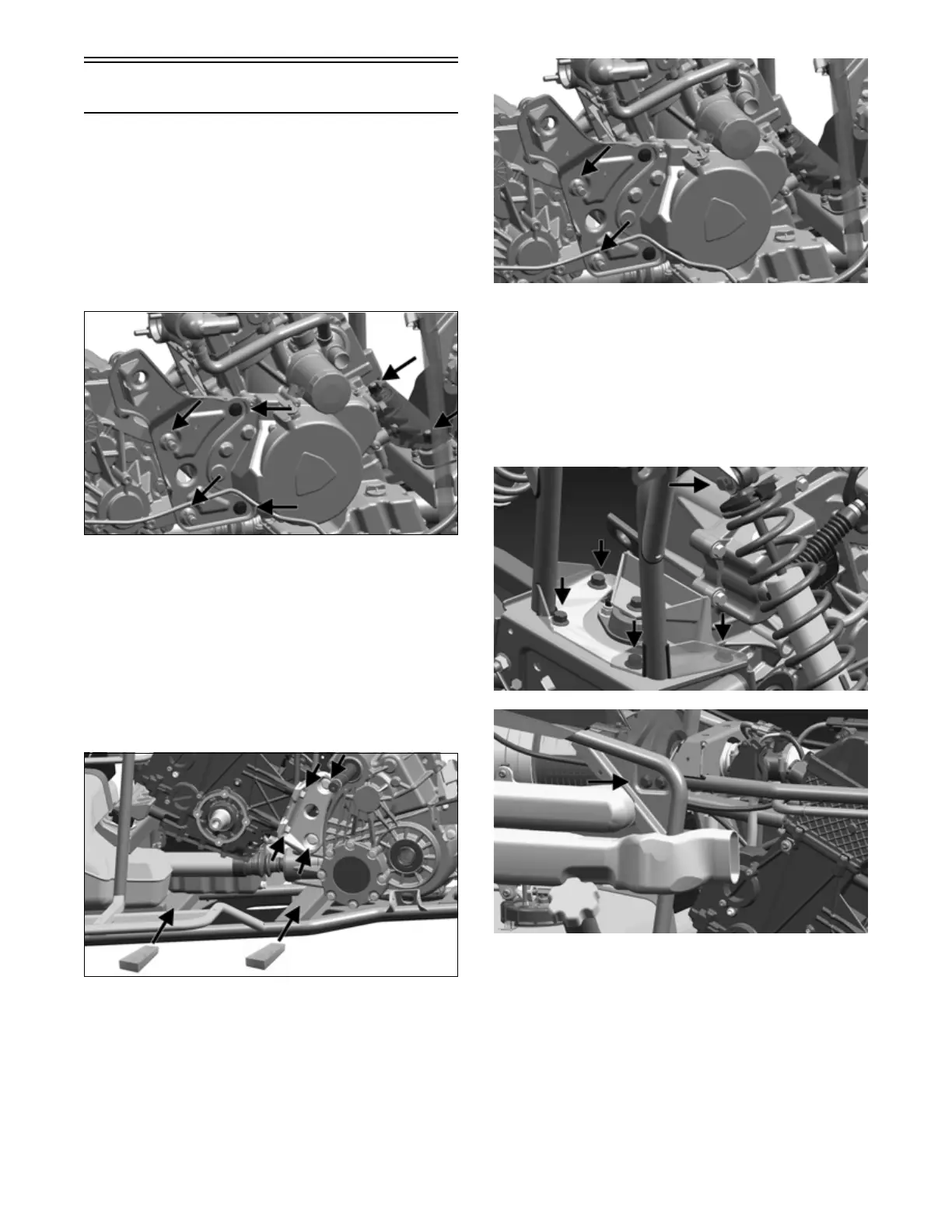

1. Carefully place engine down into position using

blocks to aid in locating proper height. Replace any

shims used to properly locate engine in chassis in

previously marked locations.

2. Install the right-side mounting plate and secure to

engine with two bolts. Tighten to 45 ft-lb (61 N-m).

Then install two new front engine mounting bracket

lock nuts on engine mounting studs. Tighten to 35

ft-lb (47.5 N-m).

OHA142

3. Install the left-side mounting bracket and secure to

engine with cap screws. Tighten to 45 ft-lb (61 N-m).

Then install two bolts through left-side mounting

bracket and transaxle, and secure with two new lock

nuts on right-side plate. Tighten to 75 ft-lb (101.7

N-m). Remove blocks.

NOTE: If additional alignment is needed to insert

bolts, gently use a suitable tool to pry up under the

engine or transaxle, using extreme care not to damage

either.

OHA141

OHA142B

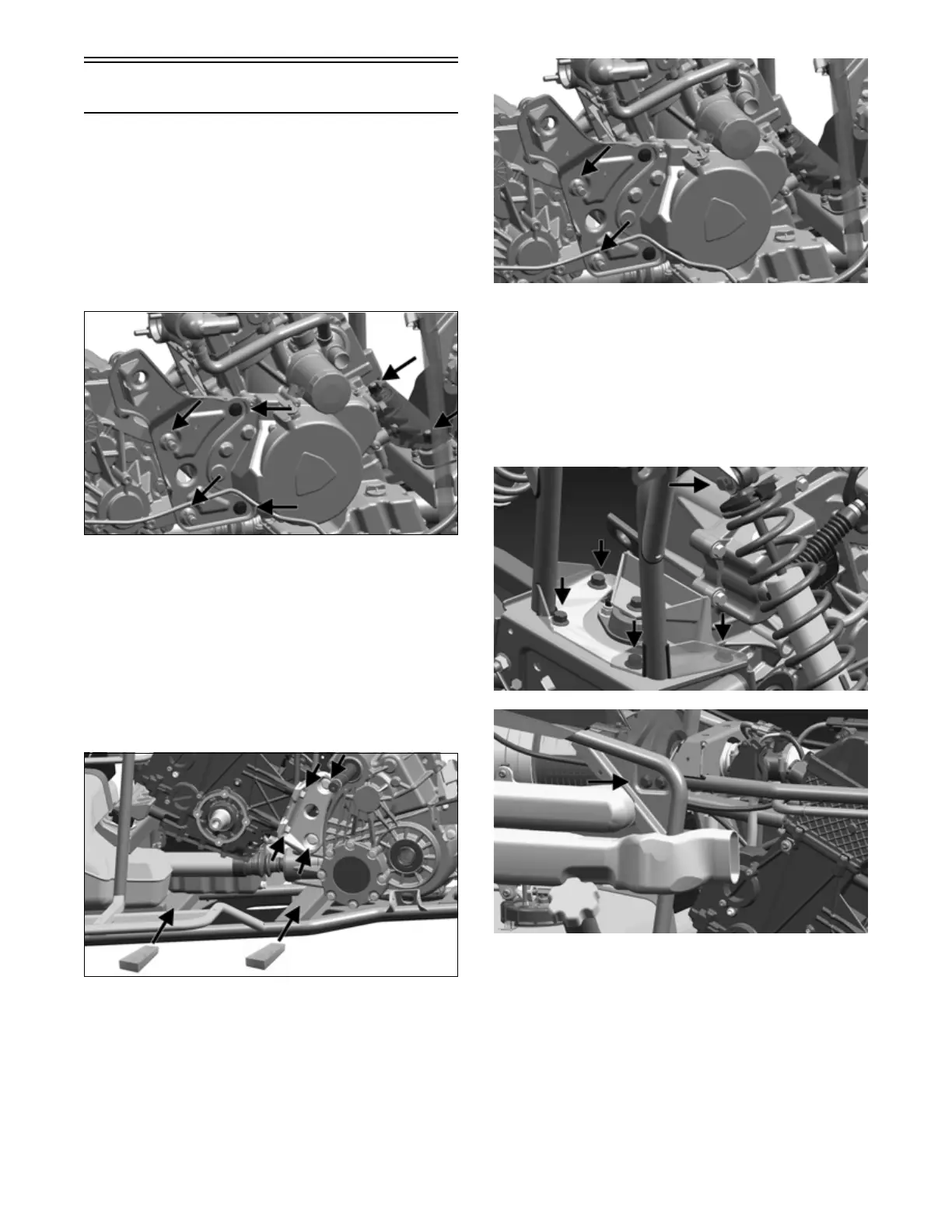

4. Place upper frame into position and secure front with

cap screws. Tighten to 35 ft-lb (47.5 N-m). Secure

rear upper frame to lower frame with four cap screws

and new nuts. Tighten to 42 ft-lb (56.9 N-m). Secure

upper rear shocks to frame with bolts and new lock

nuts. Tighten to 42 ft-lb (56.9 N-m).

NOTE: If muffler was removed, reattach to upper

frame.

OHA116

OHA117

5. Assemble exhaust pipe to engine, account for seal,

and secure with new lock nuts. Do not tighten at this

time. Then with gasket and exhaust pipe square to

muffler, secure with springs. Tighten engine-side

lock nuts to 20 ft-lb (27.1 N-m).

NOTE: It is important that the exhaust pipe and

gasket attachment to the muffler is square to prevent

exhaust leaks.

Loading...

Loading...