71

Gas Tank

REMOVING

1. Remove the seat, right- and left-hand side panels,

and left-hand footwell.

NOTE: Removing the CVT intake/inlet duct makes

it easier to remove the gas tank.

2. Remove battery bracket, and disconnect (negative

cable first) and remove battery.

3. Remove cable tie holding coolant hose to gas tank

bracket.

4. Remove the cap screw holding the starter relay sole-

noid and the two cap screws holding the winch sole-

noid (if equipped) to the tank bracket and move both

solenoids aside. Remove cap screw holding tank

bracket to the frame and remove bracket.

OHA078

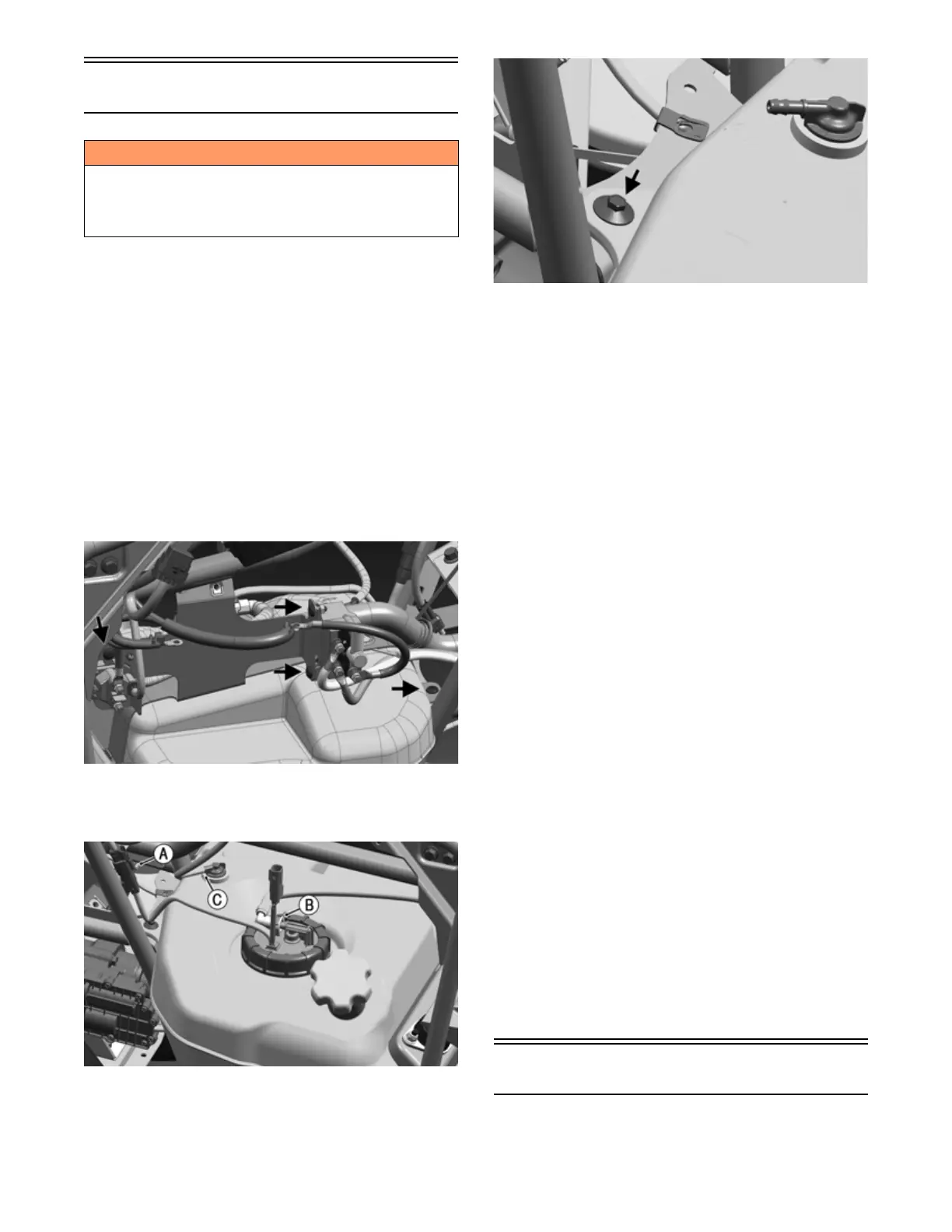

5. Disconnect the fuel pump connector (A) and gasline

hose (B) from the fuel pump. Remove the vent hose

(C) and cap the vent fitting.

OHA079

6. Remove the cable ties securing the vent hose to the

frame.

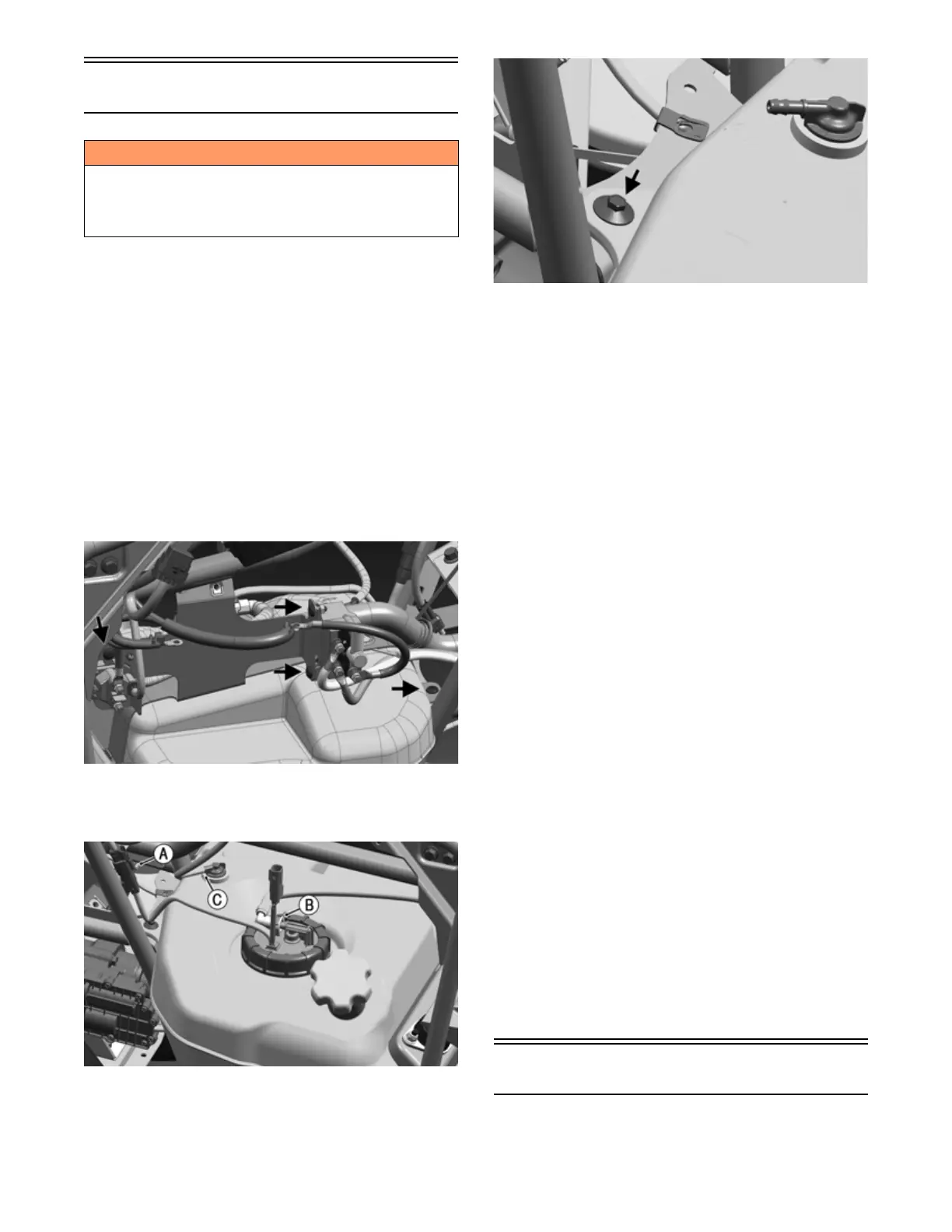

7. Remove the screw and lock nut securing the gas tank

mounting tab to the frame. Slide gas tank out from

left side.

OHA080

CLEANING AND INSPECTING

1. Clean all gas tank components with parts-cleaning

solvent.

2. Inspect all hoses for cracks or leaks.

3. Inspect tank cap and tank for leaks, holes, and dam-

aged threads.

4. Remove the fuel level sensor/fuel pick-up assembly

and inspect the fuel level sensor and fuel screen.

NOTE: If the fuel level sensor has failed or may be

faulty, see Electrical System — EFI Sensors/Compo-

nents.

INSTALLING

1. Slide the gas tank into the vehicle from the left side.

2. Secure gas tank mounting tab to the frame with

screw and new lock nut. Tighten nut to 8 ft-lb (10.8

N-m).

NOTE: Ensure the tab of the mounting bracket is in

place on the gas tank.

3. Install vent hose after uncapping the fitting. Secure

the vent hose to the frame with cable ties (as noted

during removing), then connect the gasline hose and

fuel pump connector.

4. Install tank bracket and secure to frame with cap

screw. Tighten to 8 ft-lb (10.8 N-m). Then install

starter relay solenoid and secure with cap screw and

nut with washer. Tighten to 8 ft-lb (10.8 N-m). Install

winch solenoid (if equipped) and secure with two

cap screws and nuts with washers. Tighten to 6 ft-lb

(8.1 N-m).

5. If required, reattach purge valve to tank bracket

hook.

6. Install the battery and connect the battery cables

(positive cable first); then install the battery bracket.

7. Install the fenders; then install the side panels and

seat.

Oil Pump

TESTING OIL PUMP PRESSURE

NOTE: The engine must be warmed up to the speci-

fied temperature for this test.

! WARNING

Whenever any maintenance or inspection is made on

the fuel system during which there may be fuel leakage,

there should be no welding, smoking, open flames, etc.,

in the area.

Loading...

Loading...