72

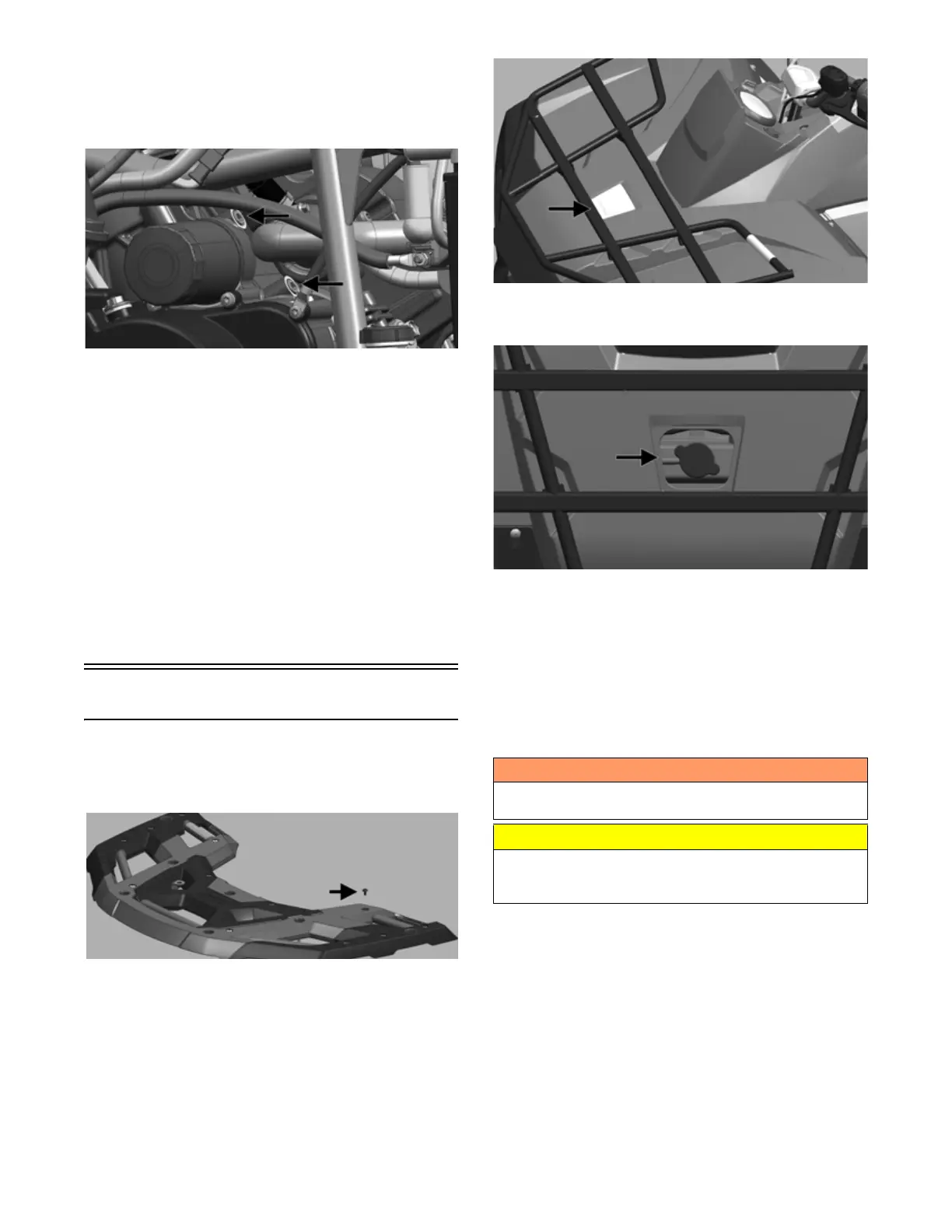

1. Connect the Tachometer to the engine or utilize the

LCD gauge.

2. Connect the Oil Pressure Test Kit to the oil pressure

test port according to manufacturer’s instructions.

OHA121

NOTE: Some oil seepage may occur when installing

the oil pressure gauge. Wipe up oil residue with a

cloth.

3. Start the engine and run at idle. With the oil tempera-

ture at 140° to 212° F (60° to 100° C), the oil pres-

sure gauge must read 20 to 80 psi (1.5 to 6.0 bar).

4, Oil pressure at 3000 RPM should read 35 to 80 psi

(2.5 to 6.0 bar).

NOTE: If the oil pressure is lower than specified,

check for low oil level, or defective oil pump.

NOTE: If the oil pressure is higher than specified,

check for too heavy engine oil weight (see General

Information/Foreword), clogged oil passage, clogged

oil filter, or improper installation of the oil filter.

Liquid Cooling System

CHECKING/FILLING

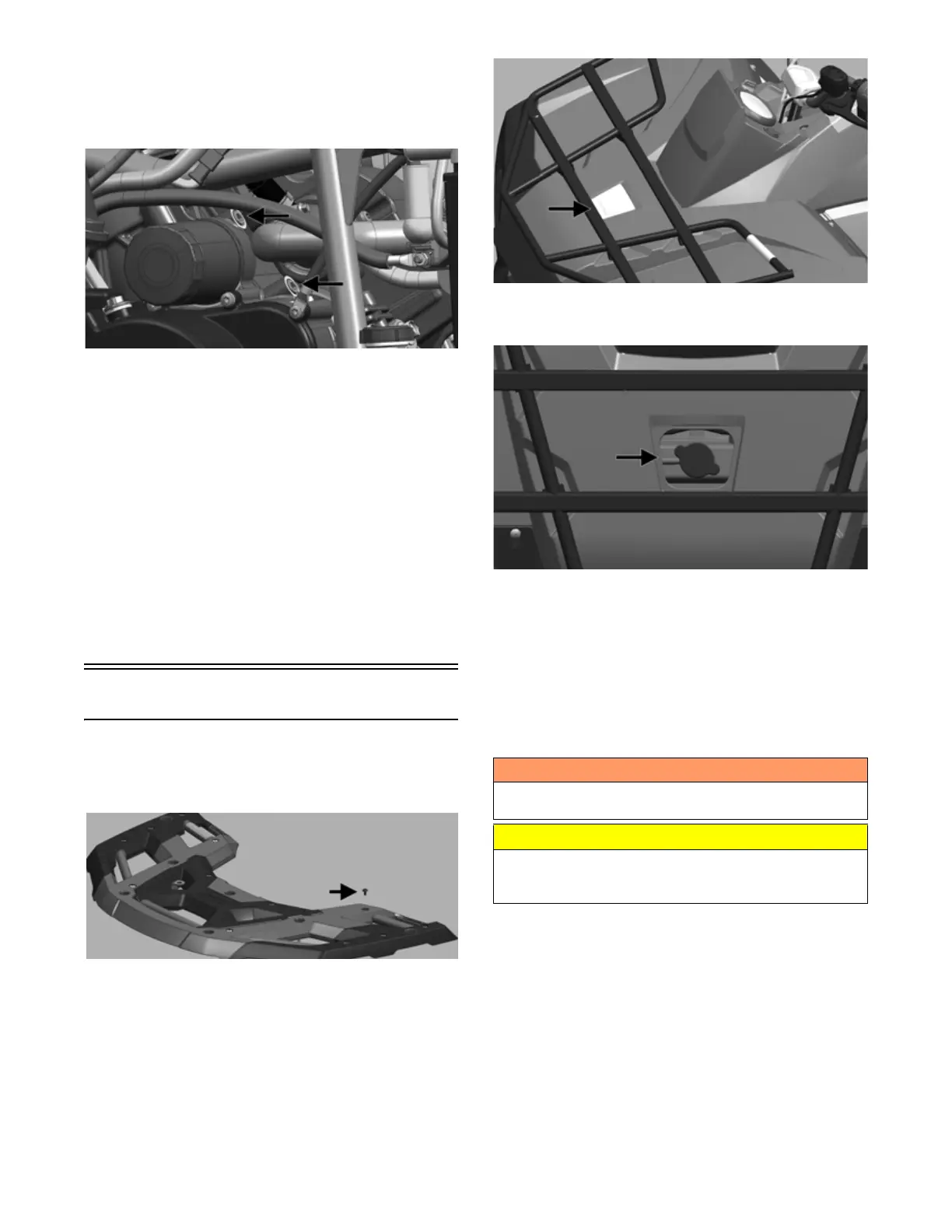

1. If equipped, remove 12 screws holding rack over-

mold to rack and remove overmold.

OHA052

2. Remove the rubber access plug from the front fender.

OHA013

3. Carefully rotate the radiator cap counterclockwise to

release pressure; then remove the cap.

OHA014

4. Add coolant as necessary; then install the radiator

cap and access plug. Reinstall rack overmold if

equipped.

NOTE: Use a good quality, biodegradable gly-

col-based, automotive-type antifreeze. When filling

the cooling system, use a coolant/water mixture which

will satisfy the coldest anticipated weather conditions

of the area in accordance with the coolant manufac-

turer’s recommendations.

While the cooling system is being filled, air pockets may

develop; therefore, remove the bleed screw, fill radiator

until a steady stream of coolant comes out, replace the

bleed screw and then finish filling the system.

! WARNING

Never check the coolant level when the engine is hot or

the cooling system is under pressure.

CAUTION

After operating the ATV for the initial 5-10 minutes, stop

the engine, allow the engine to cool down, and check

the coolant level. Add coolant as necessary.

Loading...

Loading...