49

LYC046

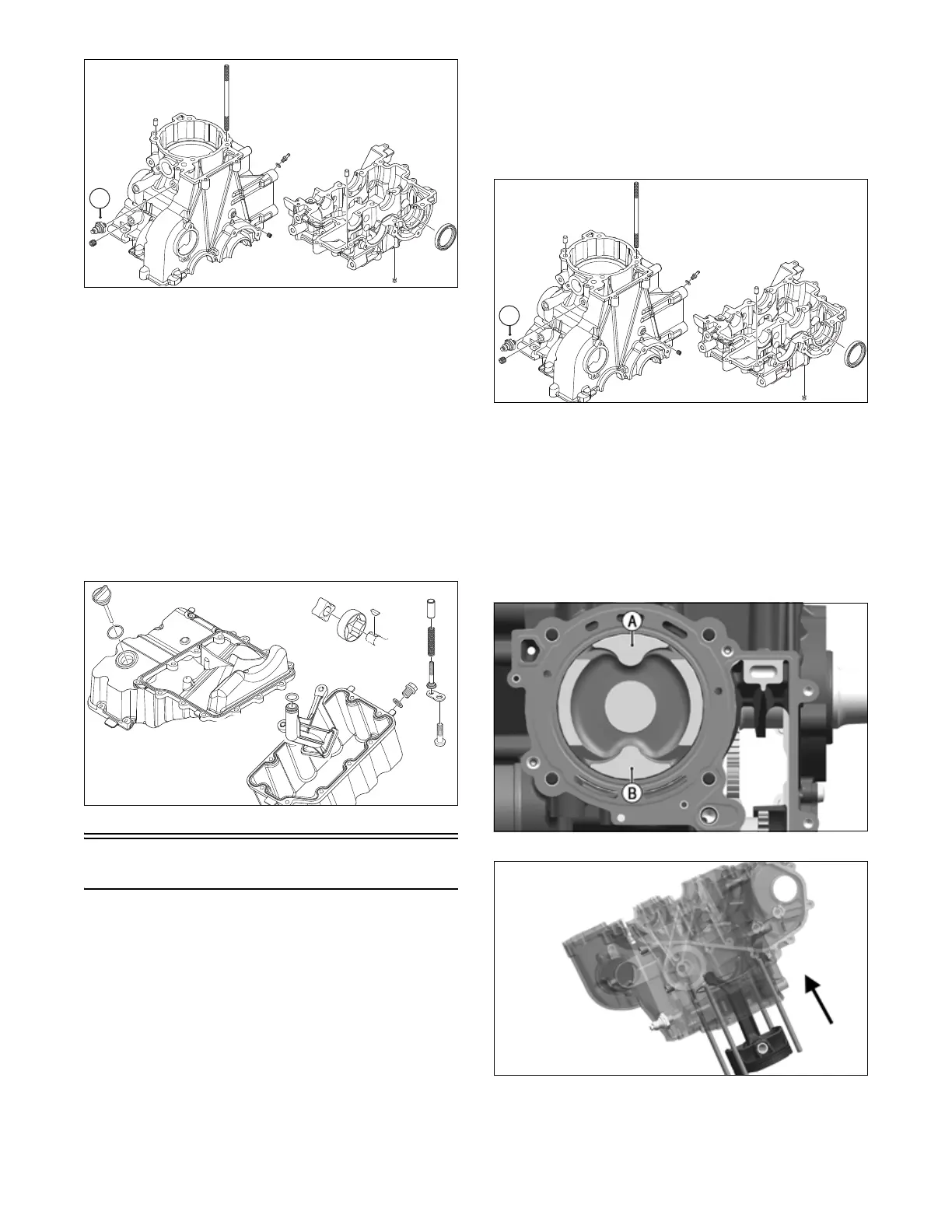

Oil Pan/Pickup/Pump/Pressure Valve

1. Remove O-Ring from oil pressure pump; then grease

and reinstall new O-ring.

2. Inspect and clean upper and lower oil pan.

3. Inspect plug, oil level stick and oil pressure pump

parts. Account for O-rings and key.

4. Oil pressure valve is located in lower crankcase.

Remove one screw holding clamp and remove and

inspect pressure valve, guide, and spring. Check for

ease of movement. Replace parts if damaged.

5. Reinstall valve, guide, and spring. Secure with clamp

and one screw. Tighten to 16 ft-lb (22 N-m)

LYC049

Assembling Engine

NOTE: The manufacturer recommends that new

gaskets, seals, and O-rings be installed whenever

assembling the engine.

NOTE: For assembly purposes, use oil-dissolvable

molybdenum disulfide grease as engine-assembly

grease.

NOTE: Refer to the Assembly Schematic at the end

of this section for visual checks and to verify parts.

1. Install four new studs in upper crankcase so the bolt

protrusion is 178 mm ± 2 mm. Tighten to 15 ft-lb ±

1.5 ft-lb (20 N-m ± 2 N-m).

2. Visually check that all fittings, sleeves and plugs are

in place and accounted for in the crankcase halves

(see Assembly Schematic at the end of this section).

3. The water pump can be assembled to the upper

crankcase at this time. Do not install the hose at this

time (see Fuel/Lubrication/Cooling section).

LYC046

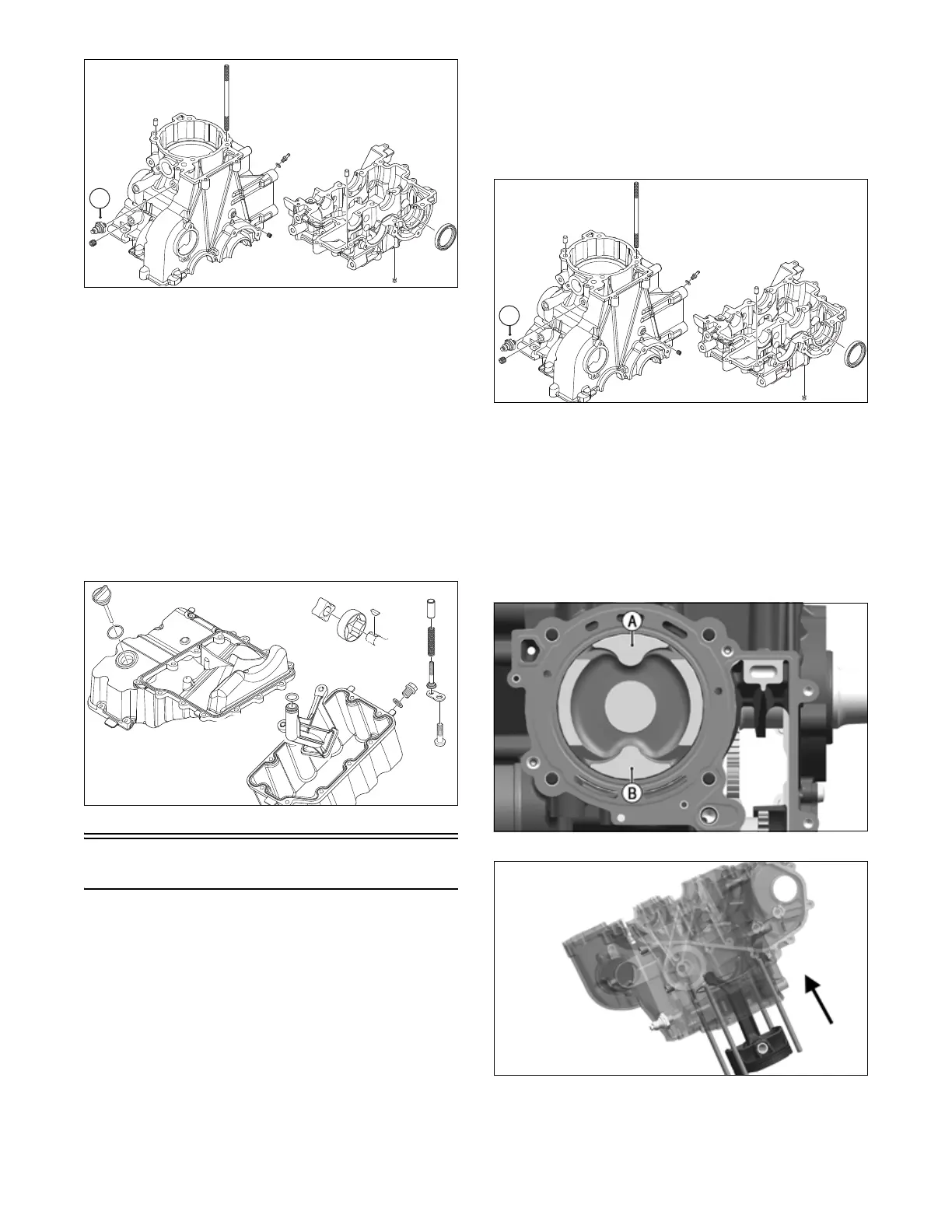

4. Verify cylinder sleeve is installed in upper crankcase

(see Servicing Engine Components — Cylinder

Sleeve). Oil piston assembly ring. Insert conrod and

piston assembly down through top of cylinder

sleeve. Orient piston top as noted when disassem-

bled. The arrow or exhaust lobe (A) should point to

starter side.

NOTE: An arrow marks the exhaust side on new

pistons and may be visible if area is clean.

LYC021

L

LYC020A

Loading...

Loading...