50

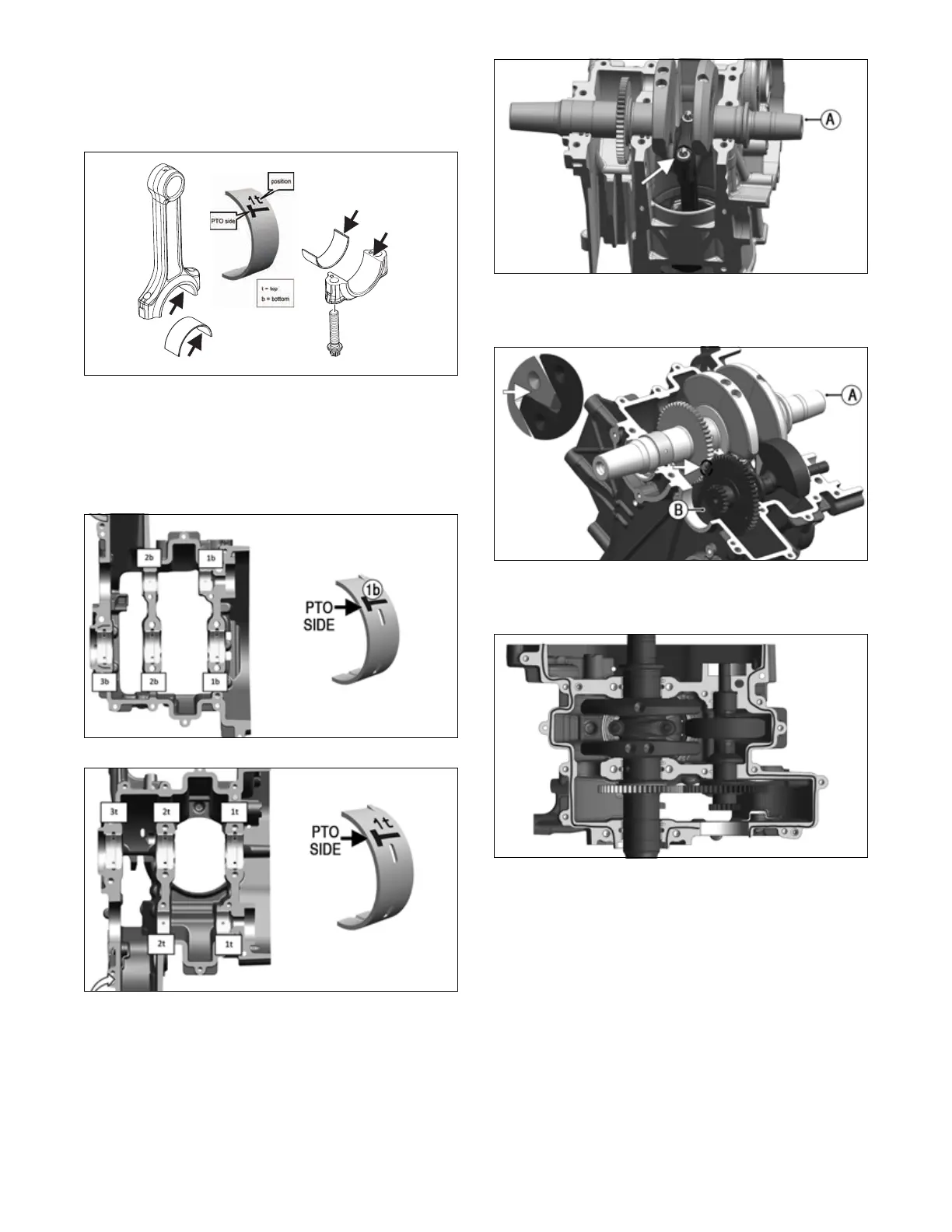

5. Clean bearing surfaces, and install conrod and con-

rod endcap bearings centered and with parting edges

of conrod halves even with bearing edges. See Ser-

vicing Engine Components — Connecting Rod

(Conrod) for bearing selection.

LYC023

6. Clean out bearing supports on crankcase halves and

install bearing halves as noted in disassembly. Place

bearings into locating notches on crankcase halves

and align bearing half edges with crankcase parting

line edges. Oil the bearings. See Servicing Engine

Components — Crankshaft for bearing selection.

LYC060

LYC061

NOTE: Prior to crankshaft and balance shaft

assembly, apply a small amount of oil on shaft bearing

journals.

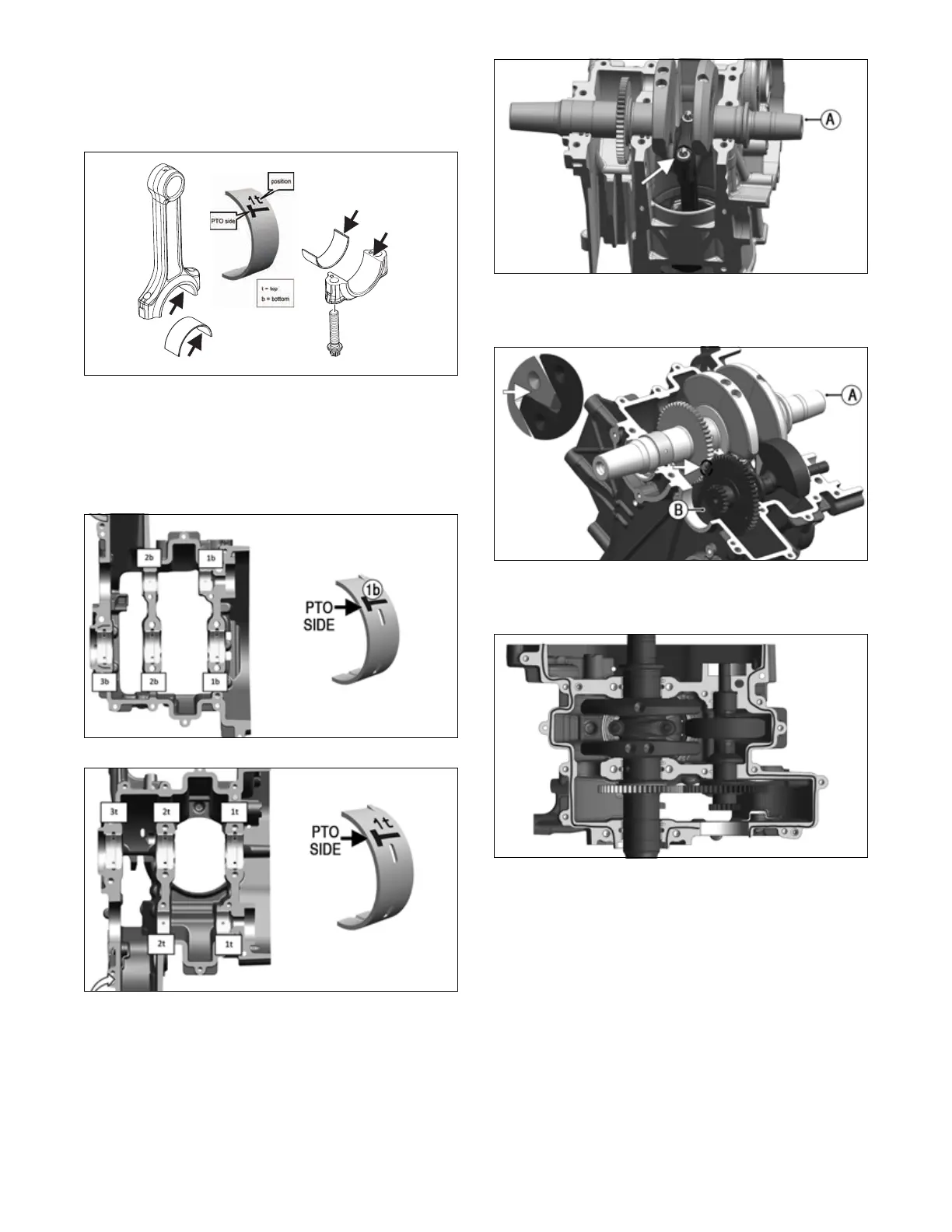

7. Install crankshaft (A) to fit with conrod. Install con-

rod end cap. Secure with two new screws. Oil bolt

heads and threads, and tighten in alternating steps:

88 in-lb (10 N-m); then 15 ft-lb (20 N-m); and finally

a 60° turn.

LYC047

8. Insert balancer shaft (B) and align sprocket marks to

crankshaft sprocket mark.

LYC064

9. Apply a thin line of liquid seal to sealing surface of

upper crankcase as indicated in illustration LYC063.

LYC063

10. Install bottom half of crankcase (A). Position using

locating pins and bearing of balancer shaft.

NOTE: Upper and lower crankcase pieces are ser-

viced as an assembly.

Loading...

Loading...