51

LYC015

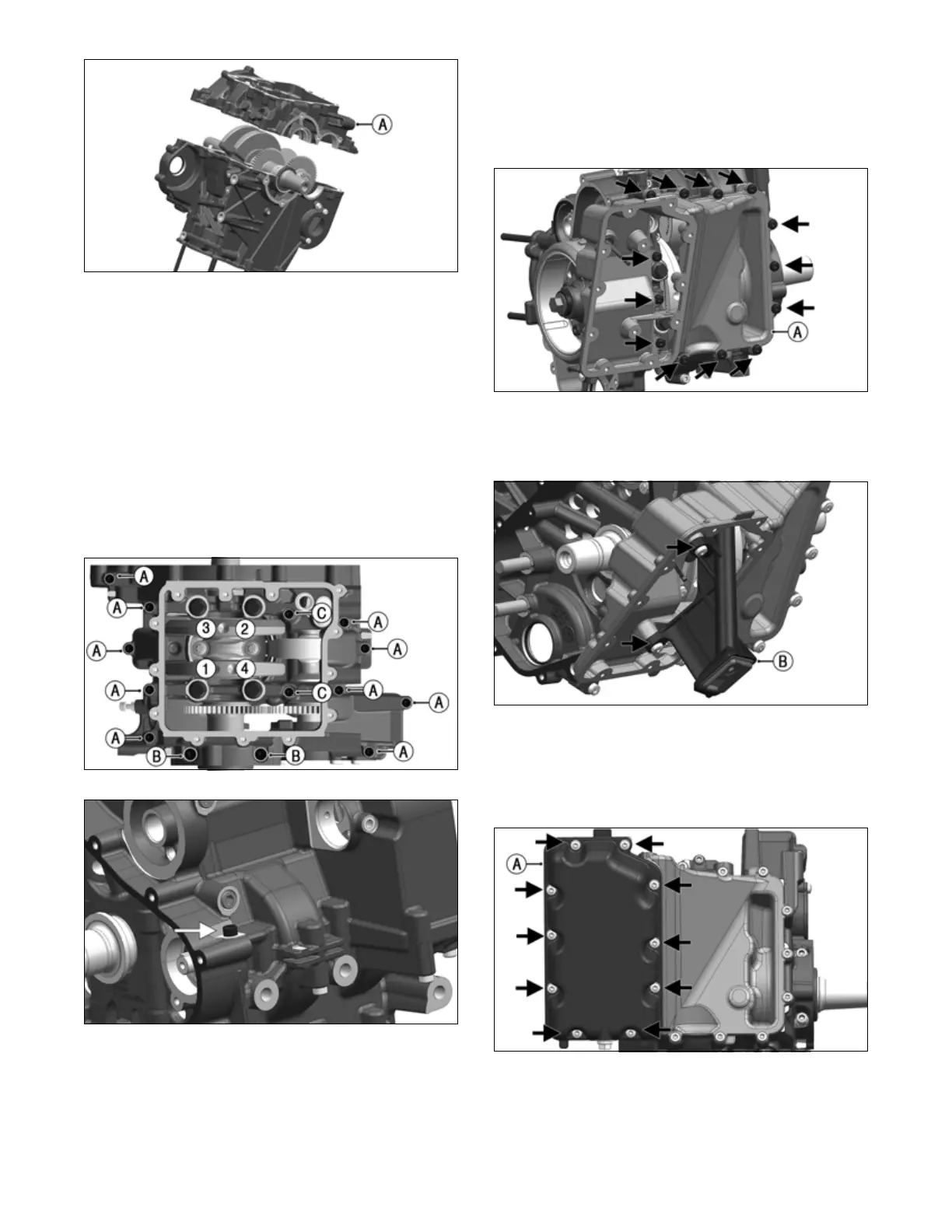

11. Secure lower crankcase to upper crankcase with 11 (one

on top) M6x35 screws (A), two M6x90 screws (B) and

two M8x40 screws (C), noting the correct location in

illustration LYC014 below. Only pre-tighten these fas-

teners. Then on the four center M8 flange bolts, lubri-

cate the threads and flange heads with mounting grease

and install in a crisscross pattern.

12. Tighten the four M8 flange bolts in a crisscross pat-

tern in steps: 88 in-lb (10 N-m); then 22 ft-lb (30

N-m): and finally a 70° turn.

13. Tighten the two M8x40 screws (C) to 17.7 ft-lb (24 N-m).

14. Tighten the two M6x90 screws (B) and 11 M6x35

screws (A) to 88 in-lb (10 N-m).

LYC014

LYC037

15. Confirm the oil pressure regulator valve is installed

on the lower crankcase (see Servicing Engine Com-

ponents — Oil Pan/Pickup/Pump/Pressure Valve

section).

16. Clean sealant surface on bottom of lower crankcase

and the upper oil pan. Apply liquid seal and two

locating pins to crankcase bottom and position top

oil pan (A) on crankcase. Secure with 13 top pan

screws: three on inside and 10 on outer edges.

Tighten to 88 in-lb (10 N-m).

OHA009

17. Install oil pickup assembly (B), account for O-ring

and secure with two screws. Tighten to 88 in-lb (10

N-m).

OHA011

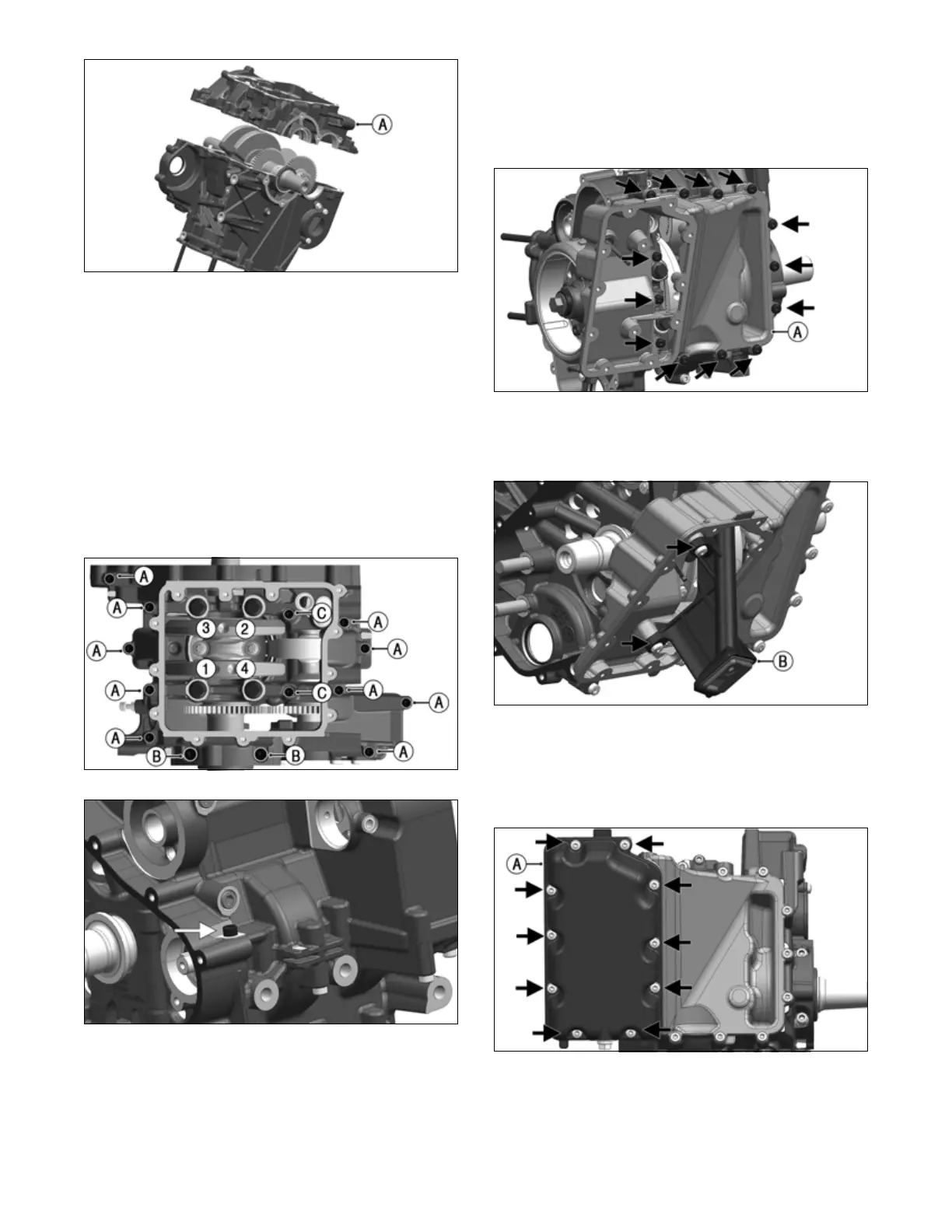

18. Clean sealing surface on upper oil pan and lower oil

pan. Apply liquid seal and place two locating pins

onto upper oil pan. Position lower oil pan (A) and

secure to upper pan with 10 screws. Tighten to 88

in-lb (10 N-m).

LYC010

19. Check that the oil drain with seal ring and oil dip

stick with O-ring are installed (see Servicing Engine

Components section or refer to Assembly Sche-

matic).

Loading...

Loading...