52

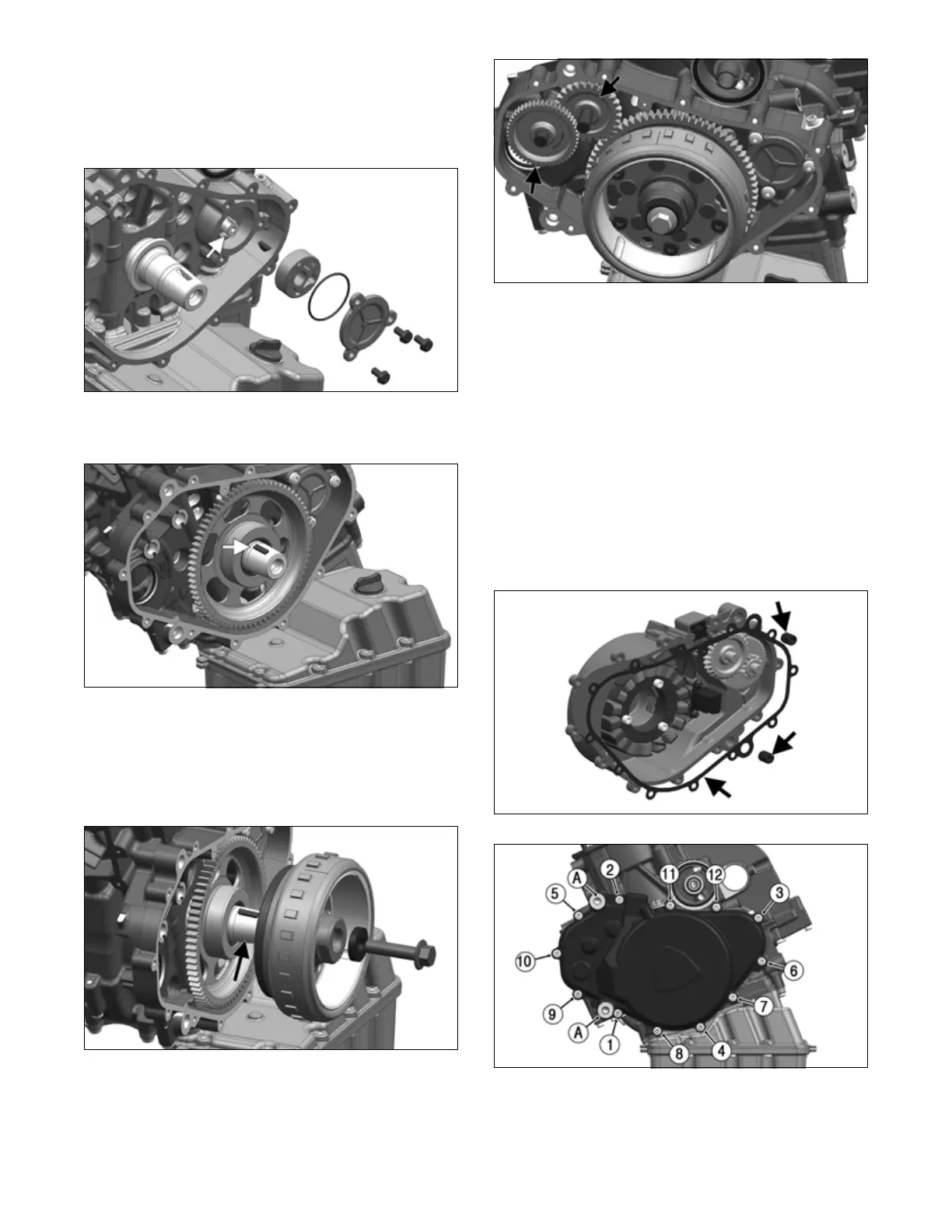

20. Wipe out any residual liquid seal in bore for oil pres-

sure pump. Insert key in balancer shaft and then

insert oil pressure pump. Install new O-ring on oil

pressure pump cover. Secure oil pressure pump cover

to crankcase with 3 screws. Tighten to 45 in-lb (5

N-m).

LYC013

21. Oil and install ring gear on crankshaft. Insert mag-

neto key in crankshaft.

LYC051

22. Clean outer taper on crankshaft and inner taper on

rotor with alcohol and slide rotor assembly on shaft

aligning with key. Install washer and bolt. Tighten to

88 ft-lb (120 N-m). Verify free rotation of large

starter gear in the counterclockwise direction. The

gear should lock up in the clockwise direction.

LYC052

23. Oil and install starter gear shafts and then install the

two starter gears on the crankcase in the direction

noted when during disassembly.

LYC053

24. Position locating pins on crankcase. Make sure seal-

ing surface of generator cover and crankcase are free

of dirt and residual sealant. Use locating pins to posi-

tion new gasket on crankcase. Then install cover

using locating pins, making sure to squarely align the

cover to crankcase. Remove locating pins.

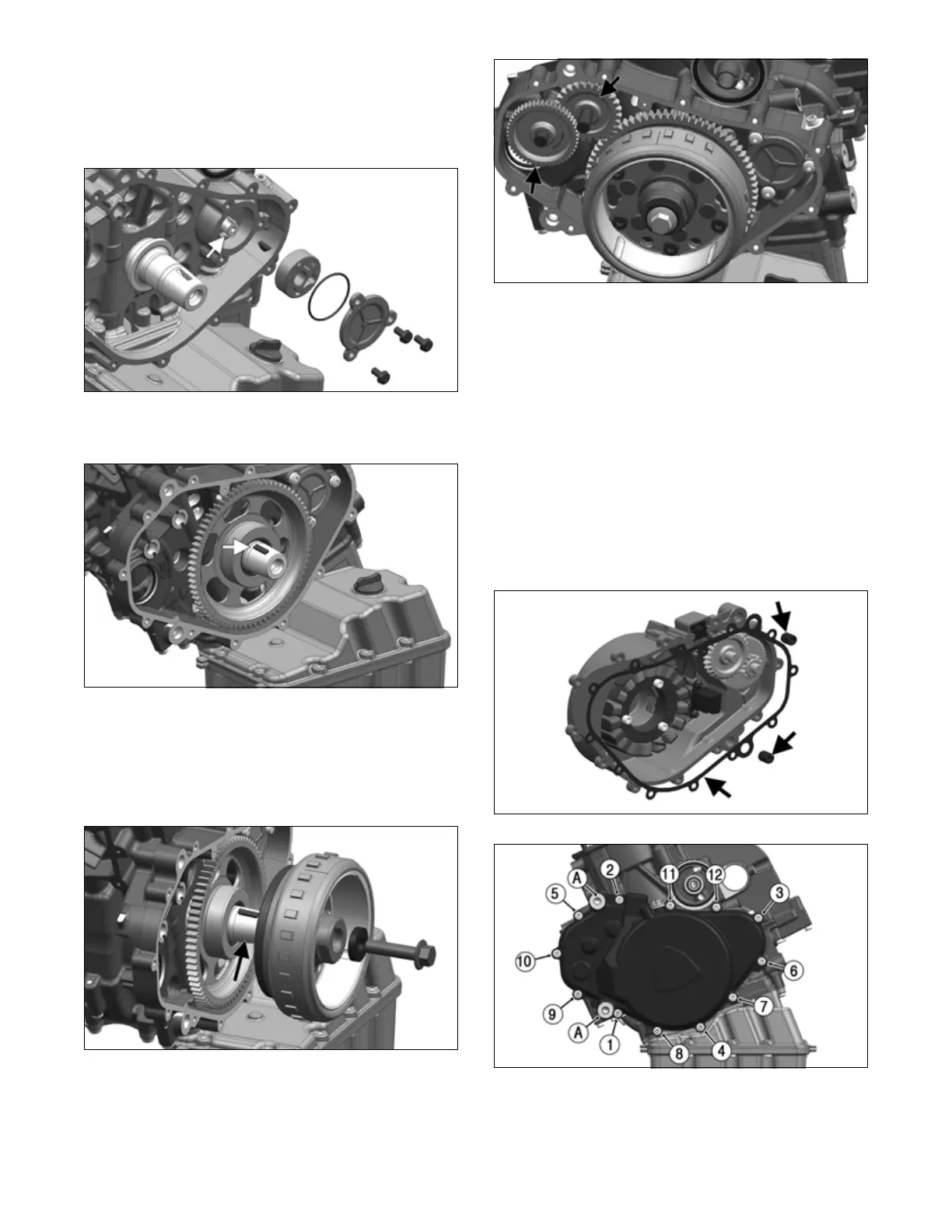

25. Install a 3.5 mm washer and a M10 bolt into each of

the two engine-to-transaxle plate mounting holes

(A). Tighten M10 bolts to 35 ft-lb (47.5 N-m).

Secure cover to the crankcase with 12 screws.

Tighten to 88 in-lb (10 N-m) in the sequence shown.

Remove M10 bolts and washers.

26. Visually check that the plug and insert are installed

on cover (see Assembly Schematic at end of this sec-

tion).

LYC008B

LYC008A

27. Make sure threaded sleeve is pushed into the bore of

chain tensioner guide rail (see Servicing Engine

Components section).

Loading...

Loading...