80

* After correcting condition, cycle key switch On-Off-On.

TROUBLESHOOTING

NOTE: The EPS assembly is not serviceable and

must not be disassembled or EPS warranty will be

voided.

1. Check 30-amp EPS fuse.

2. With the ignition off, disconnect 2-pin connector on

the EPS assembly and connect a meter set to DC

voltage to the harness (black meter lead to BLK and

red meter lead to BRN).With the ignition switch in

the ON position, the meter should read battery volt-

age (if correct voltage is not present, check connec-

tions and wiring harness).

3. With ignition switch off, disconnect the 8-pin con-

nector on the EPS assembly and connect a meter set

to DC voltage to the harness (red meter lead to the

ORG wire and black meter lead to battery ground.)

With the ignition switch in the on position, the meter

should read battery voltage (if correct voltage is not

present, check for loose fittings or connections in the

wiring harness).

NOTE: If, after completing the preceding tests and

possible solutions with normal results, an EPS issue

persists with active DTCs C1301-C1305, 1316, or

C1326-C1329 confirmed by the Dealer Diagnostic

System, the EPS assembly must be replaced (see

Steering/Body/Controls).

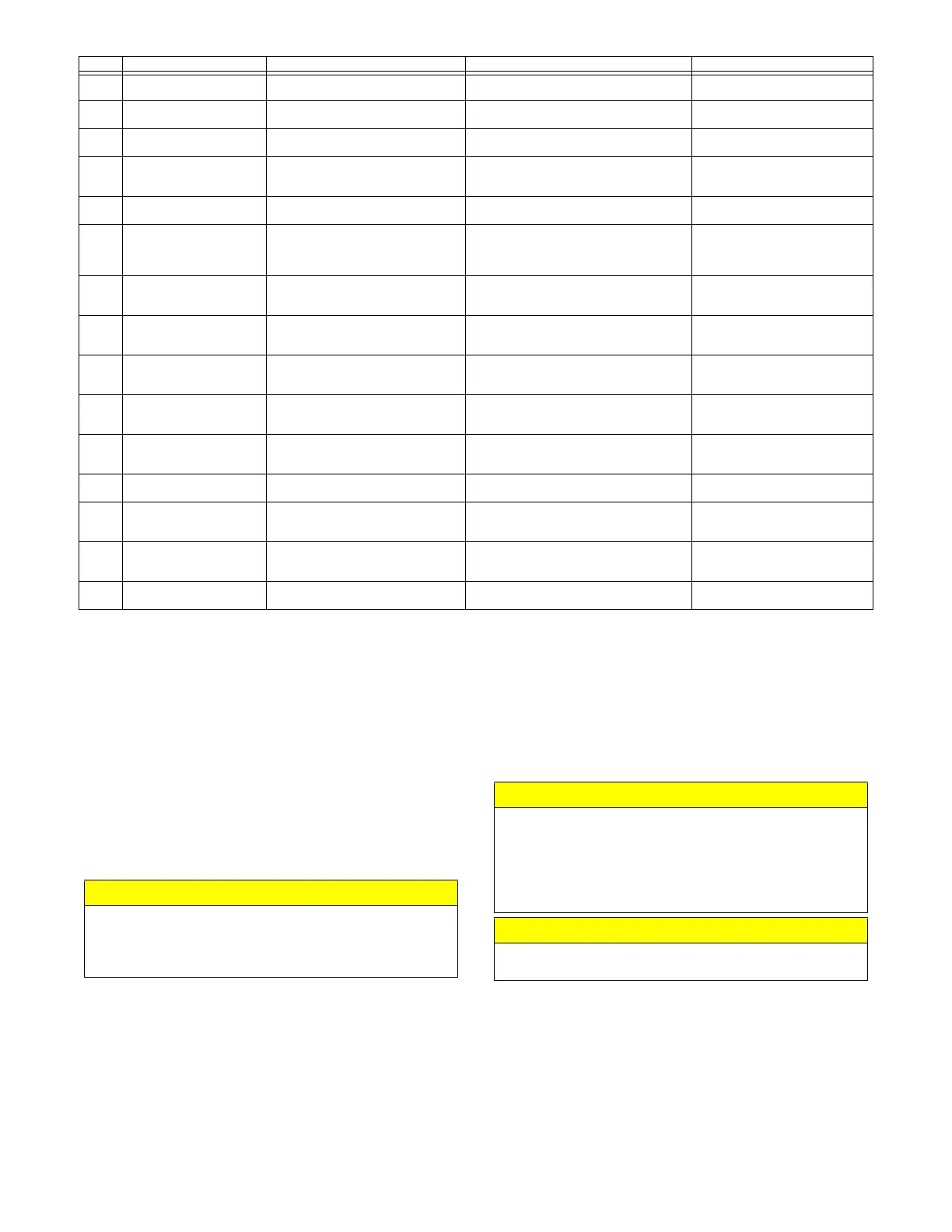

C1315 Engine RPM Faulty Engine RPM CAN signal received by

the EPS incorrect or missing

Broken main harness CAN wires or

defective ECM

EPS will auto-recover when engine

RPM signal returns to normal

C1316 EEPROM Error EPS internal memory error has been

detected

Internal EPS condition Correct EPS condition*

C1317 CAN Bus Error EPS has lost CAN communication

with the EFI ECM

Broken CAN wires in the main harness. EFI

ECM connector has been disconnected.

Correct EPS condition*

C1318 Internal CRC Error EPS internal CRC calculation

condition has been detected

EPS reflash has failed. Battery power was

lost, or the key switch was turned off, during

EPS reflash programming.

EPS must be reprogrammed

C1319 Boot Counter Exceeded EPS internal application code

condition has been detected

Intermittent power has prevented a

successful application code launch

Correct EPS power condition*

C1320 Incorrect Vehicle

Speed-to-RPM Ratio

Vehicle speed signal received by the

EPS exceeds 10 mph (16 km/h), but

the engine RPM signal less than 500

RPM

Intermittent or broken main harness RPM

wires, intermittent voltage regulator,

intermittent or broken ACG stator wires

Correct EPS condition*

C1321 Vehicle Speed Erratic Vehicle speed signal received by the

EPS changing at an unrealistic rate

Intermittent main harness, intermittent

speed sensor, dirty speed senor or trigger

wheel

Correct EPS vehicle speed signal

condition*

C1322 Engine RPM Lost Engine RPM signal received by the

EPS exceeds 500 RPM and then is

zero or missing

Handlebar switch in the “OFF” position,

broken main harness RPM wires, defect

voltage regulator, broken ACG stator wires

EPS will auto-recover when engine

RPM signal returns to normal

C1323 “EPS OFF” Gauge Display Battery power has been applied to the

EPS for more than 5 minutes, but no

engine RPM signal has been detected

EPS has been automatically disabled, after

5 minutes of inactivity, to conserve battery

power

EPS will auto-recover when engine

is started or the key switch is

cycled On-Off-On

C1324 Loss of CAN

communication with EPS

unit

Gauge has lost CAN communication

with the EPS

Broken CAN wires in the main harness or

disconnected EPS. This is not an EPS

generated DTC; gauge DTC display only.

Gauge DTC display will clear when

the EPS-to-gauge CAN

communication is restored.

C1325 Dual Loss EPS loss of both the vehicle speed

and the engine RPM signals has been

detected

Handlebar switch in the “OFF” position, the

engine stalled (key switch “ON”), broken

harness wires, loss of CAN data signal

EPS will auto-recover when either

the vehicle speed or engine RPM

signal is restored.

C1326 Rotor Position Encoder EPS internal rotor position encoder

variance condition has been detected

Internal EPS Condition Correct EPS condition*

C1327 Voltage Converter Error

(Low)

EPS internal voltage converter

low-voltage condition has been

detected

Internal EPS Condition Correct EPS condition*

C1328 Voltage Converter Error

(High)

EPS internal voltage converter

over-voltage condition has been

detected

Internal EPS Condition Correct EPS condition*

C1329 Internal Data Error EPS internal preloaded data condition

has been detected

Internal EPS Condition EPS must be reprogrammed

Code Fault Description Fault Condition Possible Cause Fault Recovery Method

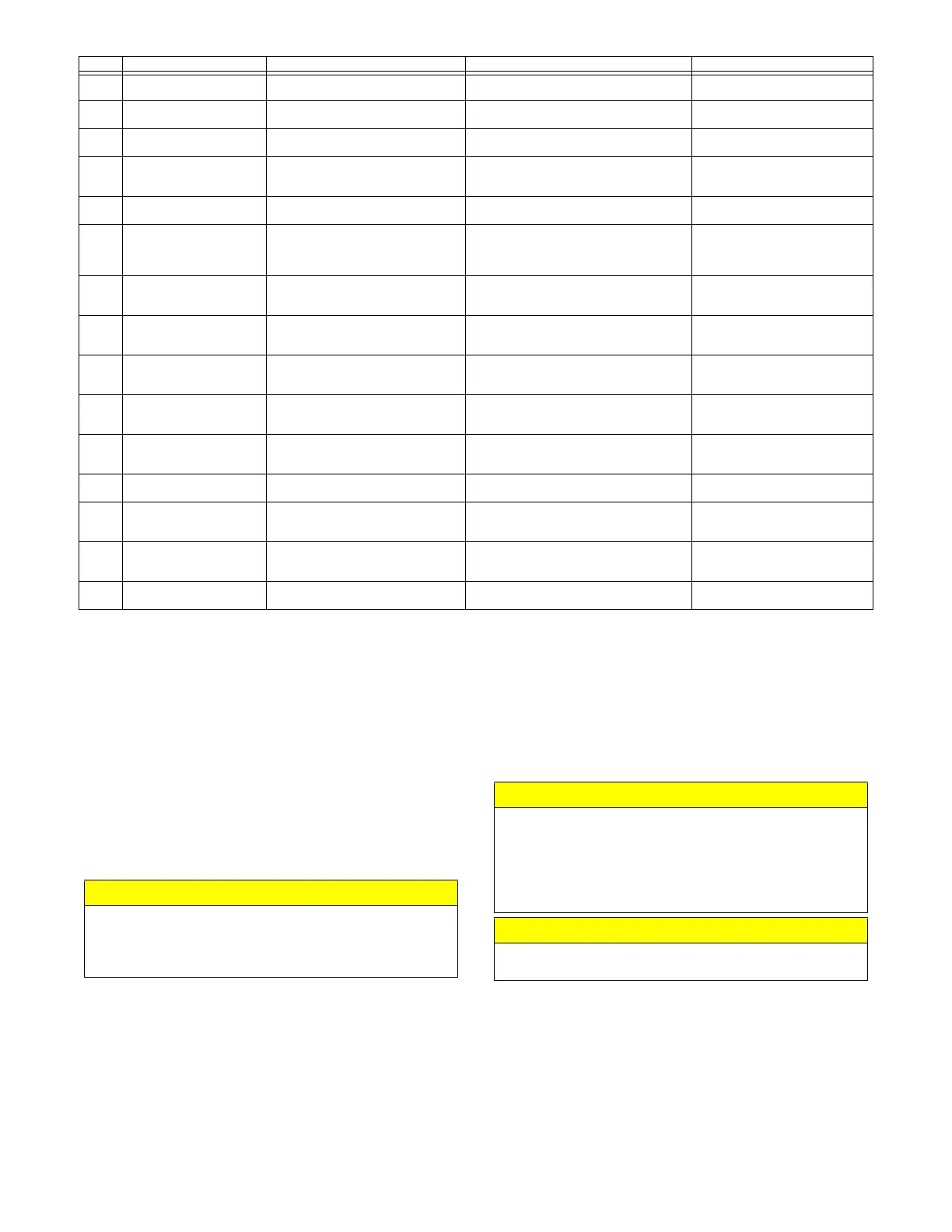

CAUTION

Do not attempt to check resistance of the EPS motor

(2-pin input receptacle). There are internal capacitors

holding a charge that can cause internal damage to an

ohmmeter.

CAUTION

If the Dealer Diagnostic System has confirmed an

active DTC relating to the CAN communication wires,

use extreme caution when testing the wires. Do not

probe the ECM connector with meter leads; instead use

a small T-pin or other suitable testing component to

make light and proper contact.

CAUTION

Never disconnect the ECM connector with the battery

cables installed onto the battery.

Loading...

Loading...