97

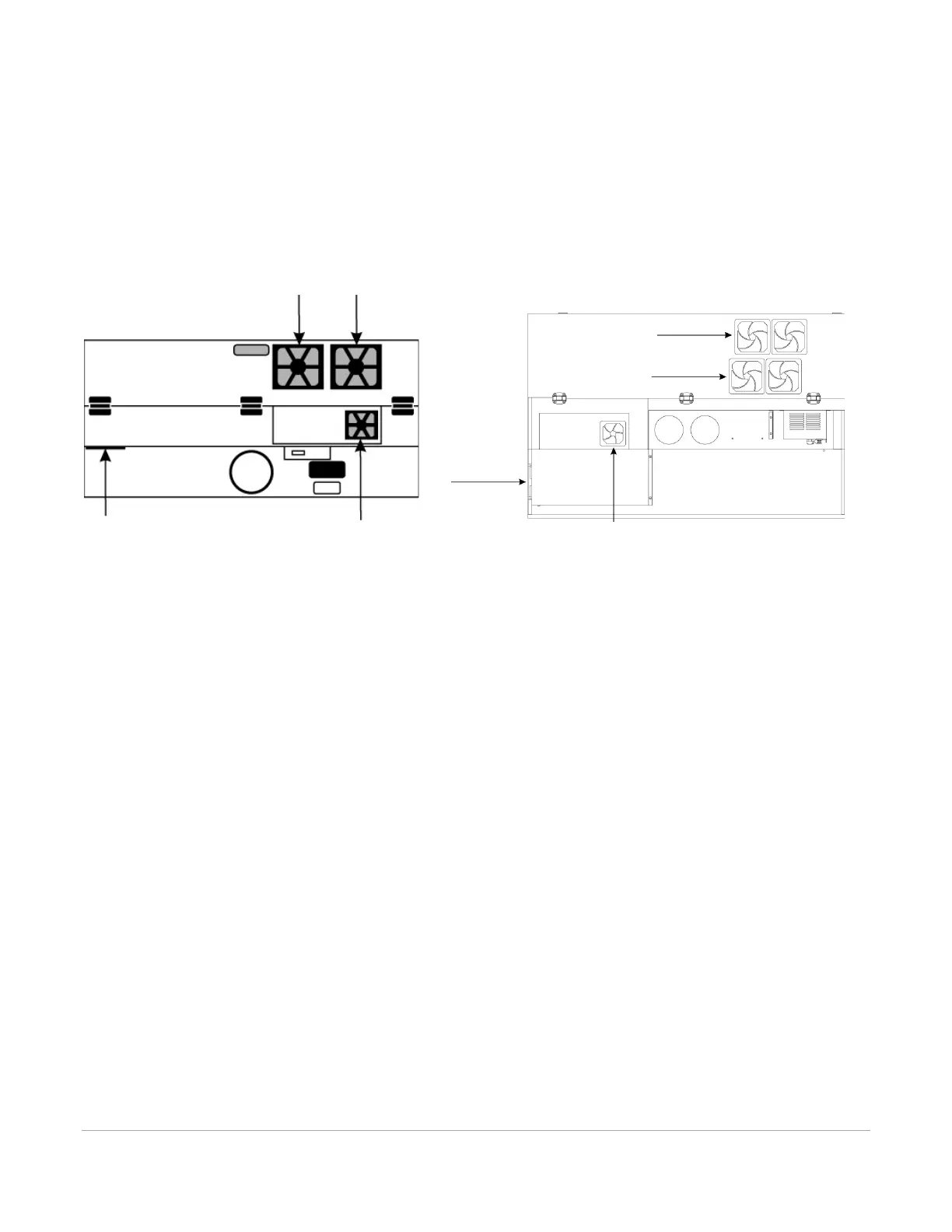

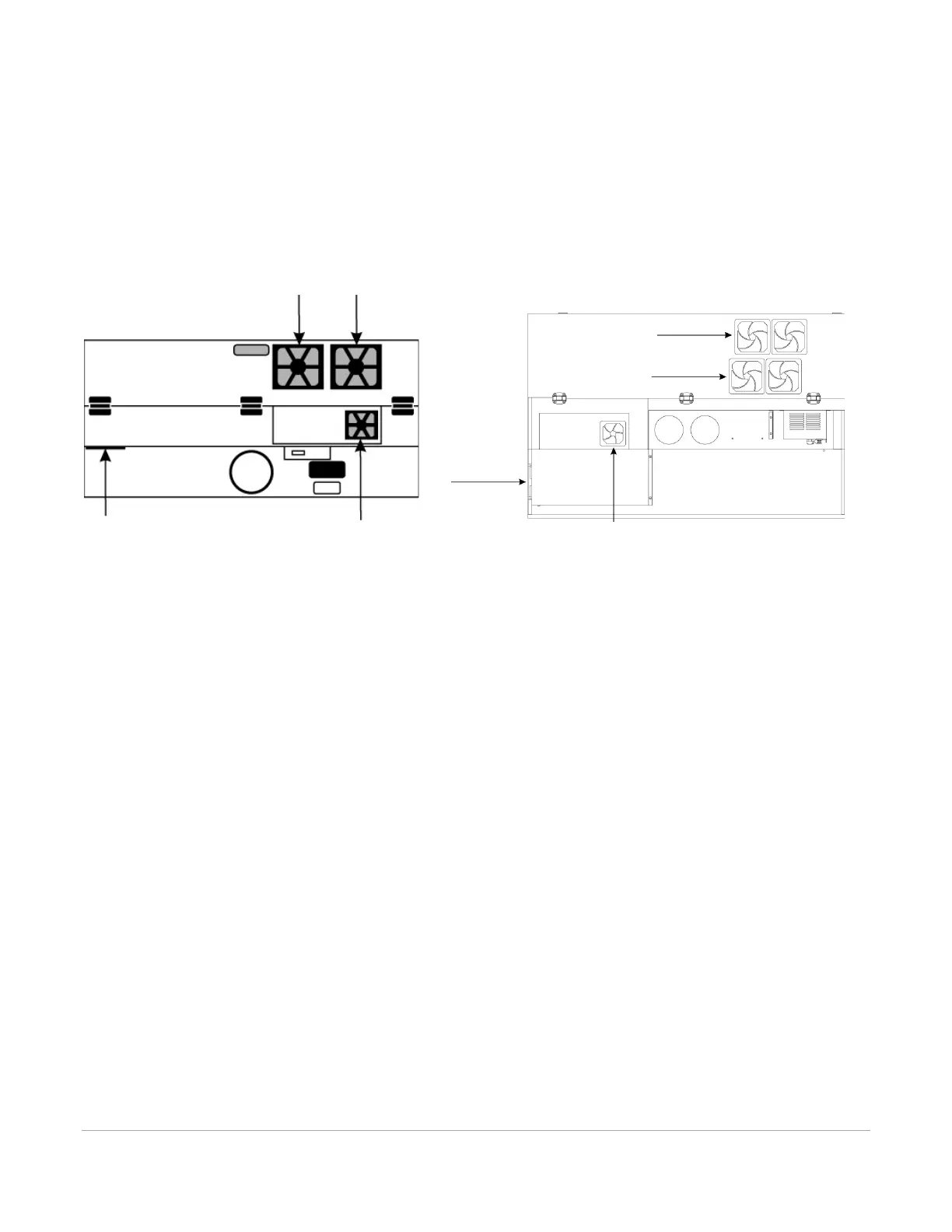

Cooling Fan Filters

This air-cooled laser system will require periodic cleaning of the cooling fan filters. Since ambient air is used to

cool a laser cartridge, the air must be filtered before it passes through the laser. Dust contamination in the

intake filter may reduce the cooling fan’s ability to keep the laser cartridge, as well as the CPU and power supply,

from overheating. An overheated laser cartridge will lose laser power during engraving and will eventually shut

down completely.

To service the filters, first turn OFF and unplug the laser system. To remove the filter(s), simply snap off the

black cover and remove the foam element. Wash the element in a soap and water solution, dry and re-install.

CAUTION: Never operate the laser system with the cooling fan filters removed as dust and debris can build up in

the laser cooling channels, thus leading to overheating.

Adjustments and Lubrication

Periodic adjustments are not normally required. The bearings in the motion system will self-adjust to take up

any clearances as they begin to wear. The belts are fiber-reinforced and will not stretch under normal use so

periodic tension adjustment is not necessary. All bearings in the system are sealed and do not require

lubrication. Do not lubricate the tracks that the bearings ride in. The only lubrication that may be required is to

the screw threads for the Z axis lifting mechanism. Over time contaminants may adhere to the lubricant which

can cause the engraving table to bind up. Periodically wipe off the contaminated grease with a soft cloth

dampened with alcohol and apply fresh white lithium grease to the screw threads. Never spray any degreasing

solutions directly onto the threads. Run the table up and down to work in the fresh grease.

Loading...

Loading...