76

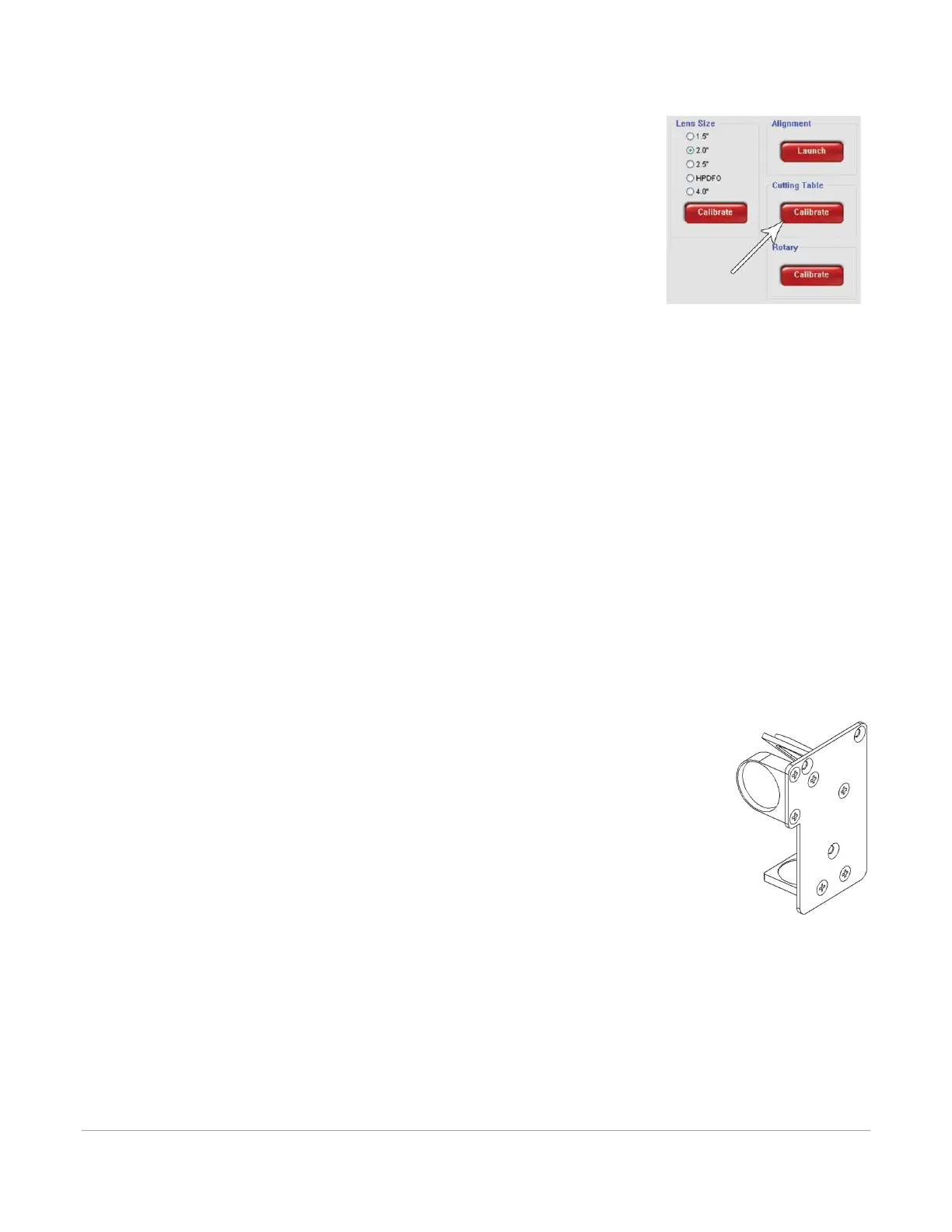

Flow-Through Cutting Table Focus Lens Calibration

CAUTION: To properly use the cutting table with the autofocus feature or the

auto-Z feature in the printer driver, the cutting table must be calibrated to

the lens you are using. This is done at the factory when the laser system

ships. You can check calibration by using the manual focus tool to focus on

the surface of the cutting table. Make sure to use the manual focus tool

included with the lens installed in the laser system and that the lens selected

in the system tab matches the lens installed in the laser system. Once

focused, the Z position indicated in the UCP should be 0” +/-.020” (.508 mm).

However, if you have to recalibrate, there is a calibrate feature in the system

tab of the UCP which will walk you through the process.

Maintenance

As you use the Flow-Through Cutting Table, material from the cutting process may fall through the

honeycomb surface and collect in the bottom of the cutting table. Periodically check this area and remove

any material that has collected there.

CAUTION: If left to build up in the bottom of the cutting table, this scrap material can be a fire hazard.

The honeycomb material that makes up the support surface for materials being cut will wear out over time

and can easily be replaced. New honeycomb can be purchased from the ULS Customer Service Team. To

replace the material, remove the rulers and flanges that hold the honeycomb in place around its edges.

Remove the old honeycomb and replace it with a new one. Reinstall the back panel. Reinstall the edge

flanges and rulers. Rulers should be installed slightly loose and then adjusted to match the edges of the

processing area by placing the cutting table back into the machine and following step 7 of the installation

instructions above.

HPDFO™

High Power Density Focusing Optics (HPDFO) has a smaller focal spot size than a standard

2.0” inch lens. Depending on the type of material being processed, the effective spot size

produced by the HPDFO can be as small as 1/4th the size of a standard 2.0” focusing lens.

With a smaller spot size (higher power density), depending on your material, you can engrave

smaller text, produce sharper graphics and photographs and vector mark and cut thinner

lines with the same laser power. With the HPDFO it is also possible to scribe and/or etch

some uncoated metals, such as stainless steel, directly without the assistance of chemicals or

coatings.

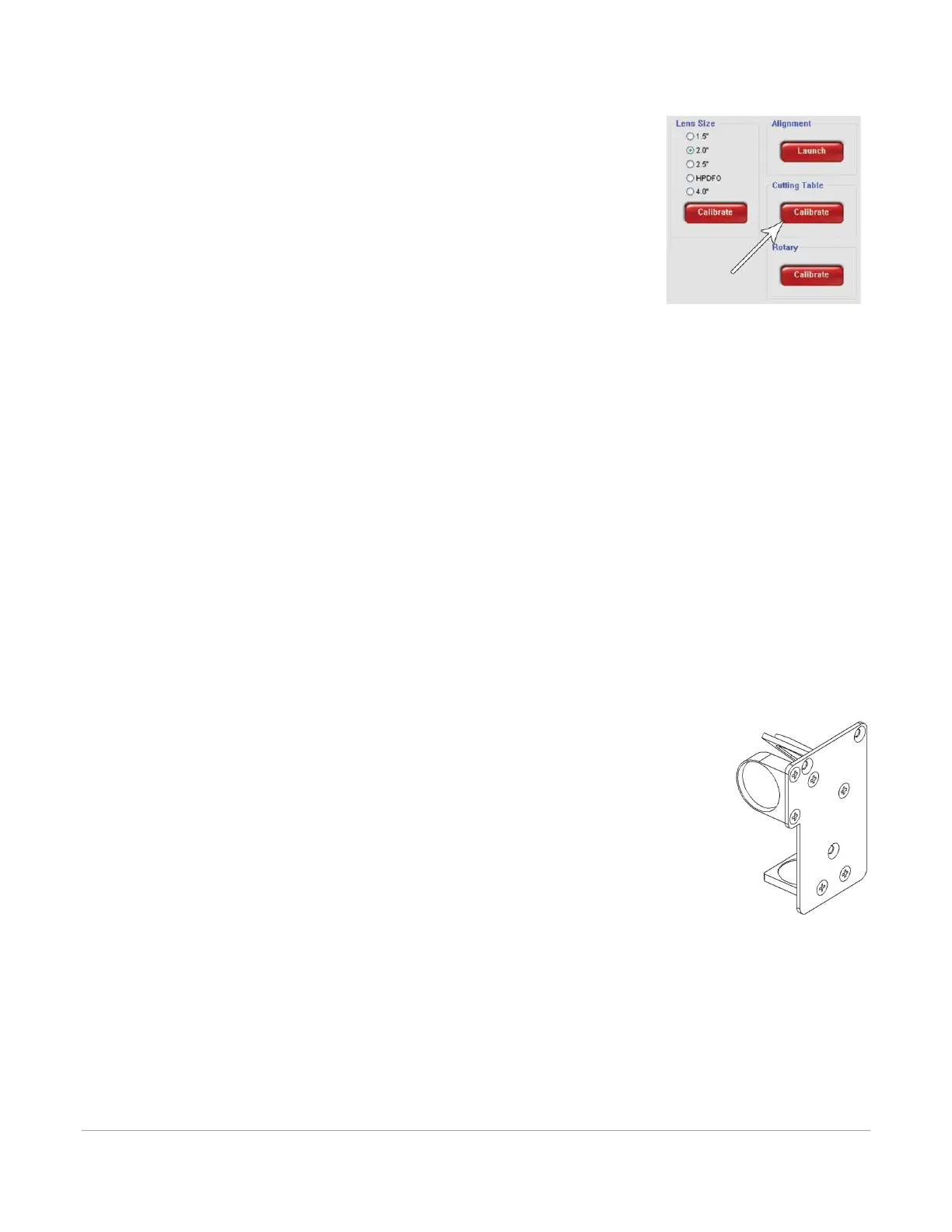

The HPDFO replaces the standard lens kit in the carriage and comes with its own calibrated focus tool which

should always be used when focusing with the HPDFO.

Installation

1. Turn off the laser system.

2. Bring the X-Arm forward by hand.

3. Remove the three thumbscrews that hold the lens kit in place and slide the lens kit out.

4. Replace the standard lens kit with the HPDFO lens kit.

5. Before running a file, select HPDFO from the lens size list on the UCP’s System Tab.

Loading...

Loading...