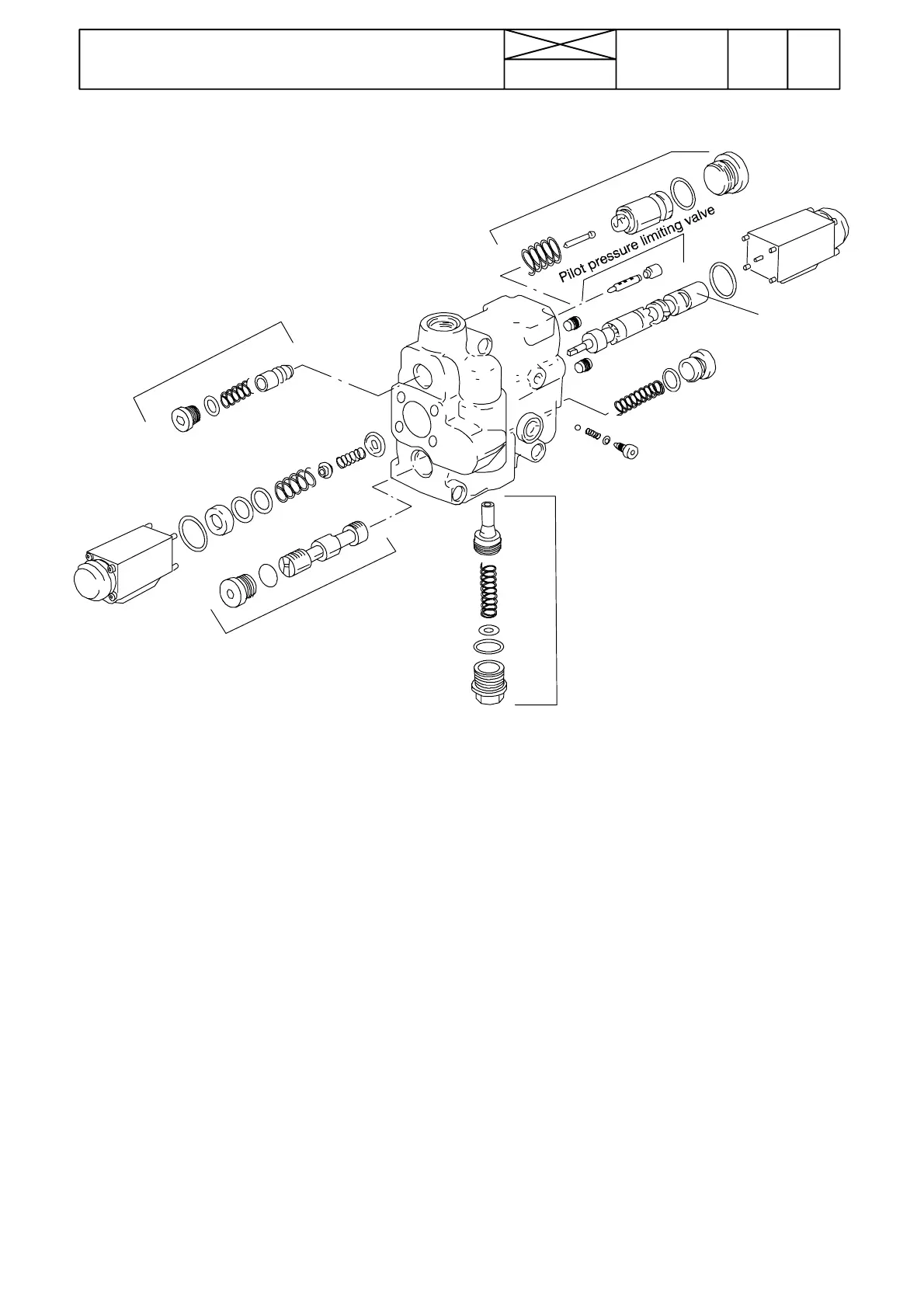

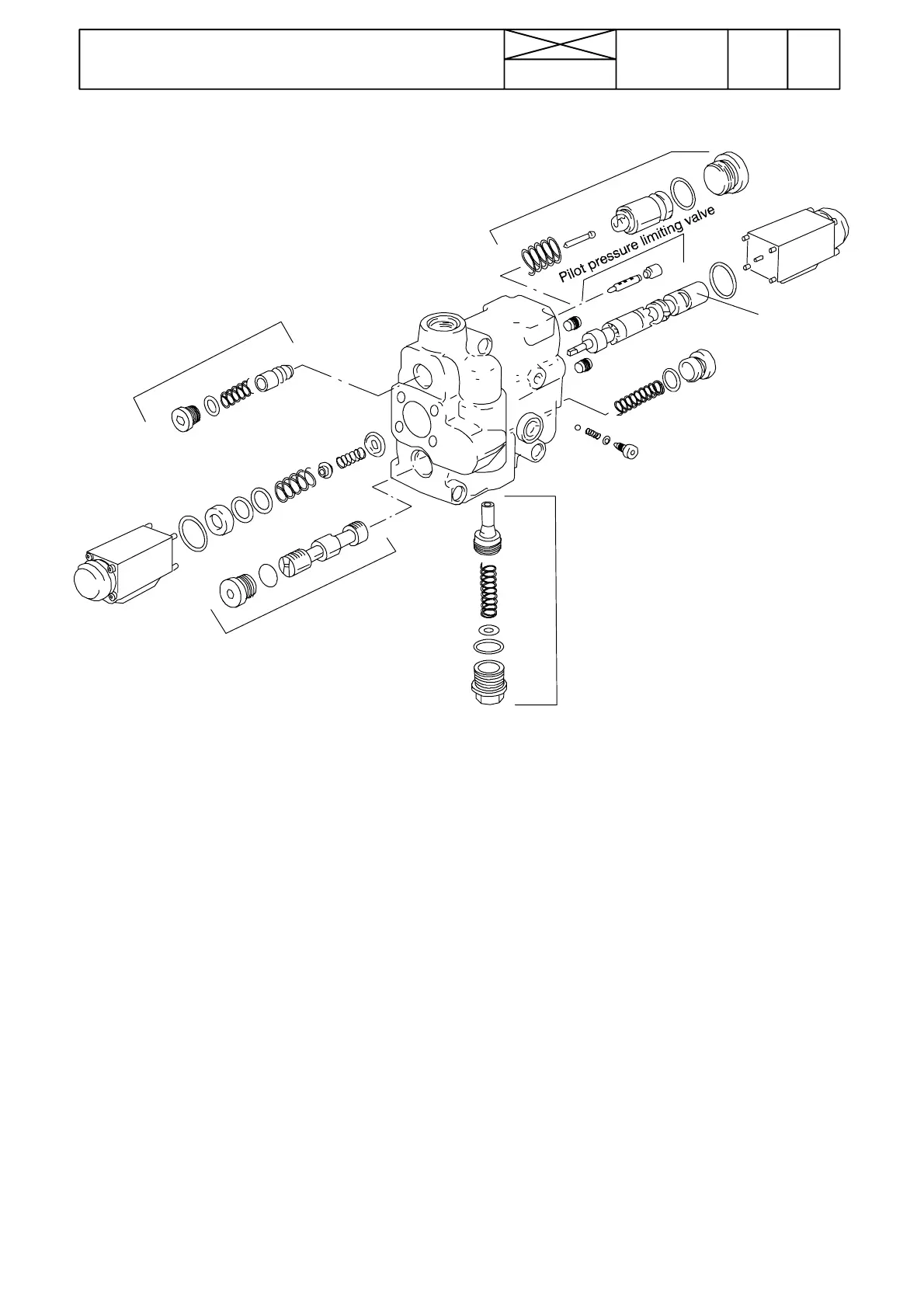

Lowering

valve

Shock valve

Lowering valve

pilot piston

3 --- way oi l f l ow re g u l a -

ting slide

Main spool

1248

Model Code Page

90. Hydraulic system

1. 8. 2000

6000--8950 912 2

15. 5. 1996

D. Reconditioning control valv e

Lowering valve

If the hydraulic power lift makes many lifting corrections(reac-

tions) per minute when a weight is attached to thethree---point

linkage, a possible fault can be faulty lowering valve (or its

pilot piston).

In this case, the lowering valve can be disassembled and

cleaned as well as the pilot piston. Leaking lowering valve

must be changed. In addition, the valve spring must be

checked and changed. Note! If the lift does not hold the load,

possible fault can also be leaky lifting cylinder piston seal.

Shock valve (20 MPa)

If the lift does not hold the load, the possible fault can also be

leaking shock valve. When the control valve is in neutral posi-

tion, the load rests on the shock valve.

In this case, open and clean the shock valve and, if necessary,

change the valve spring or adjust it with shims.

3---way oil flow regulating valve

This valve can be opened and cleaned. The valve slide must

move easily in its bore.

Pilot pressure limiting valve

Note! The new pilot valve has neither a ball nor a spring but

only a tapered valve pin and a locking nut.

The valve must not be screwed fully home, it must be opened

1/2---1 turn.

Adjusting pilot pressure:

Connect a pressure gauge to the pressure filter test point. Ac-

tivate the power lift and adjust the engine revs to 1500 rpm.

Turn the position potentiometer to lowering. Now the free cir-

culation pressure must rise 5 bar, e.g.: not activated 20 bar

and activated 25 bar.

The tighter the valve is, the greater is the lowering speed (if the

valve is tightened too great, the free flow pressure rises too

much in the lowering movement). If the valve is too loose, the

lower links do not lower at all (lowering valve does not open).

Solenoids

Solenoid valves are available as a spare part. When fitting a

new solenoid, fit the same shims onto the end of the main

spool spring. Do not tighten the solenoid screws too hard.

Tightening torques

Shock valve plug 46 Nm........................

Lowering valve plug 30 Nm......................

Pilot piston plug 103 Nm.........................

Note! When reconditioning the control valve, always fit new

sealing rings. When opening the valve plugs, use good tight

Allen keys because the plugs can be very tight. When

slackening the plugs, knock at the Allen keys with a hammer.

Loading...

Loading...