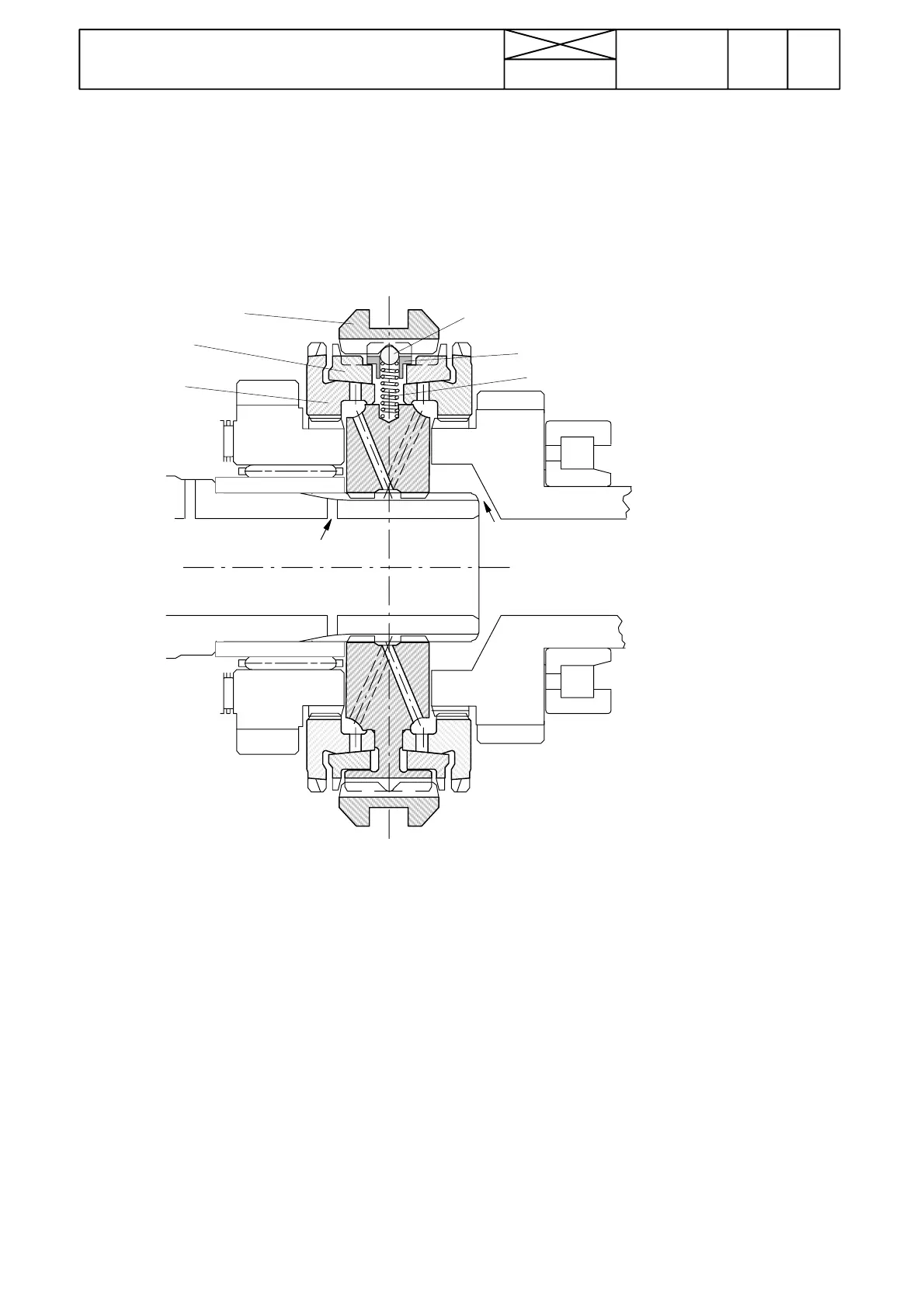

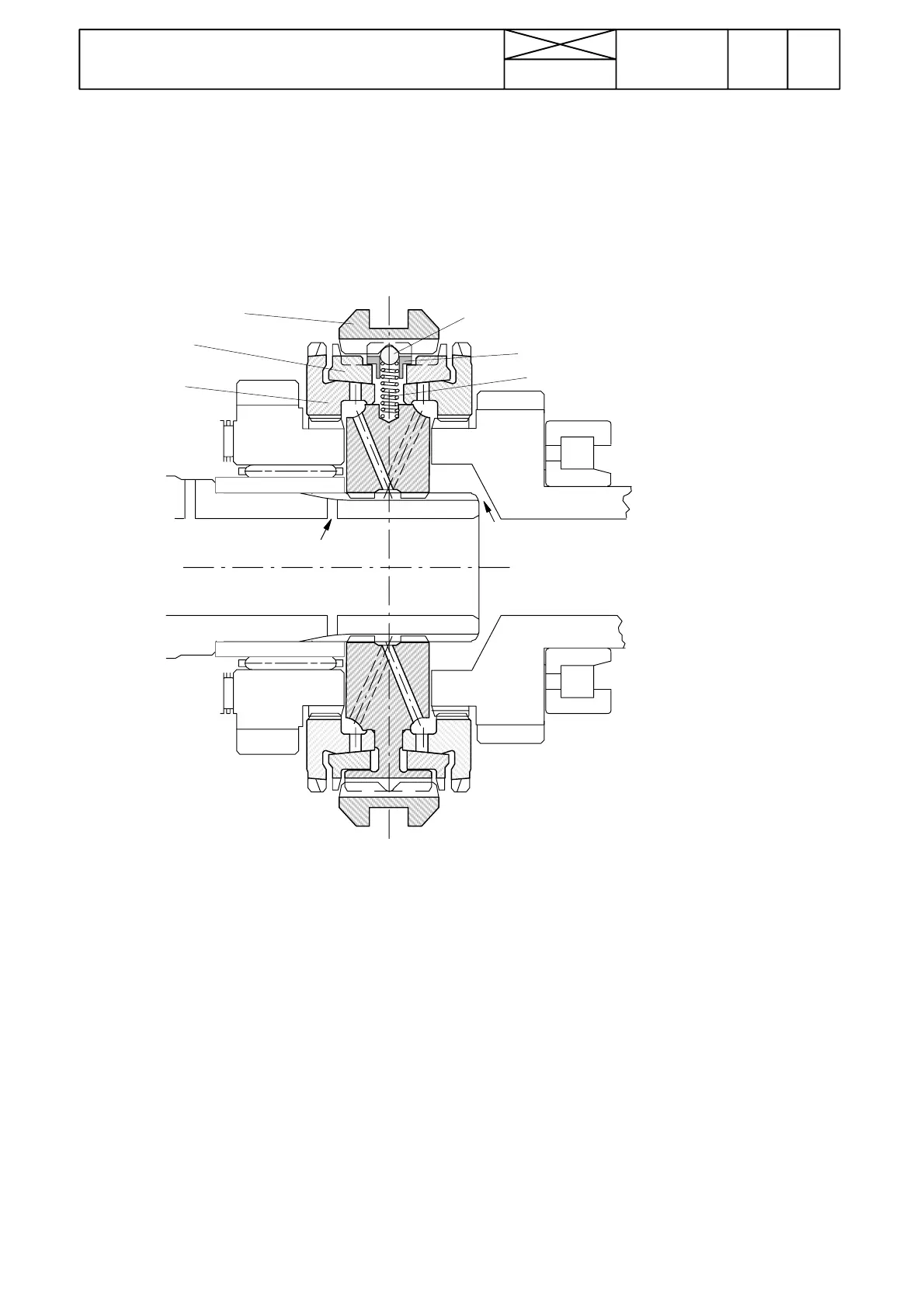

A. Sliding coupler

B. Synchronizing cone (2 pcs)

C. Coupler (2 pcs)

D. Ball (3 pcs)

E. Shoe (3 pcs)

F. S p r i n g ( 3 p c s )

678

Model Code Page

42 Gearbox

15. 5. 1993

10420

6000--8750

15. 6. 1992

Synchronization

Synchronizing cones

On input shaft (couplers for gears 1---2 and 3---4): ø82 mm,

steel

On bevel pinion shaft (coupler for ranges M and H): ø90 mm,

steel

The synchromesh units can be fitted either way. The synchro-

mesh units on the input shaft are interchangeable and can be

fitted either way. Measuring synchronizing cone wear and as-

sembling the unit, see page 423/7.

A

B

C

D

E

F

Figure 10. Synchromesh unit

Engagement

The axial movement of the sliding coupler(A) pressesthesyn-

chronizing cone (B) against the male taper on the coupler (C)

by means of the balls (D) and shoes (E). The different speeds

of the components to be coupled together produces stagger-

ing of their relative positions, limited by stops, which in turn

causes the chamfered teeth on the synchronizing cone (B) to

press against the sliding coupler (A), thereby preventing any

relative movement of this coupler. The pressure exerted by

the sliding couple r (A) and the staggered position of the syn-

chronizing cone (B) creates axial pressure between the tap-

ered friction surfaces on the synchronizing cone (B ) and the

coupler (C) by means of the chamfers on the teeth. This axial

pressure gradually reduces the difference in speeds in order

to achieve synchronization.

Once, the speeds have been synchronized, the sliding

coupl er (A) continues to exert pressure against the synchro-

nizing cone (B) and pushes it backwards until the teeth in

coupler (A) are opposite gaps between the teeth on the syn-

chronizing cone (B). At this point the resistance, which had so

far prevented the sliding coupler (A) from moving, is over-

come and the sliding coupler (A) engages silently with the

teethinthecoupler(C)

Neutral position

The sliding co upler (A) is in the middle position. Balls (D) are

pushed into the V shaped groove in the sliding coupler (A) by

springs (F). The gears can turn freely on the shaft. The sliding

coupler (A) is locked in this position by three balls (D) held by

springs (F).

Loading...

Loading...