139

Malli Koodi Sivu

37. Autocontrol 5 / 5.2

1. 9. 2002

370 19B

6250--8950

L. Check of the gas pedal sensor calibration with the computer,AC5and5.2

The check with the computer, if:

--- Calibration has not succeeded.

--- Calibration is correct but DPS has malfunctions (specially

low revs models 6750 and 8350).

1. Switch the power of the tractor off. Connect a programming

cable to the PC and to the connector X43.

tai COM2

337 006 00, L=1,5 m tai

337 006 10, L=8,0 m

340 422 60

2. Turn the PC’s power on and start Windows. Insert an AC5

programming diskette to the PC’s disk drive A:> and choose

“ VALT_TRM95_COM1 ” and start the program according to

instr. B.2 on page 370/ 24B).

3. Switch the power of the tractor on. Text “ RESET ” or

“Loader 0.4” appears if the communication is OK. In case of

malfunction try once more.

4. The computer is now ready to receive information about the

calibration. Do the calibration normally ac cording the

following instructions.

5. Activate the setting mode FIII according to instr. A on page

370/14.

6. Select in the setting mode symbol 1 (gas pedal calibration)

with the DPS push buttons (in the speed gear lever knob) and

confirm it with the DPS pre---programming button (see page

370/14)

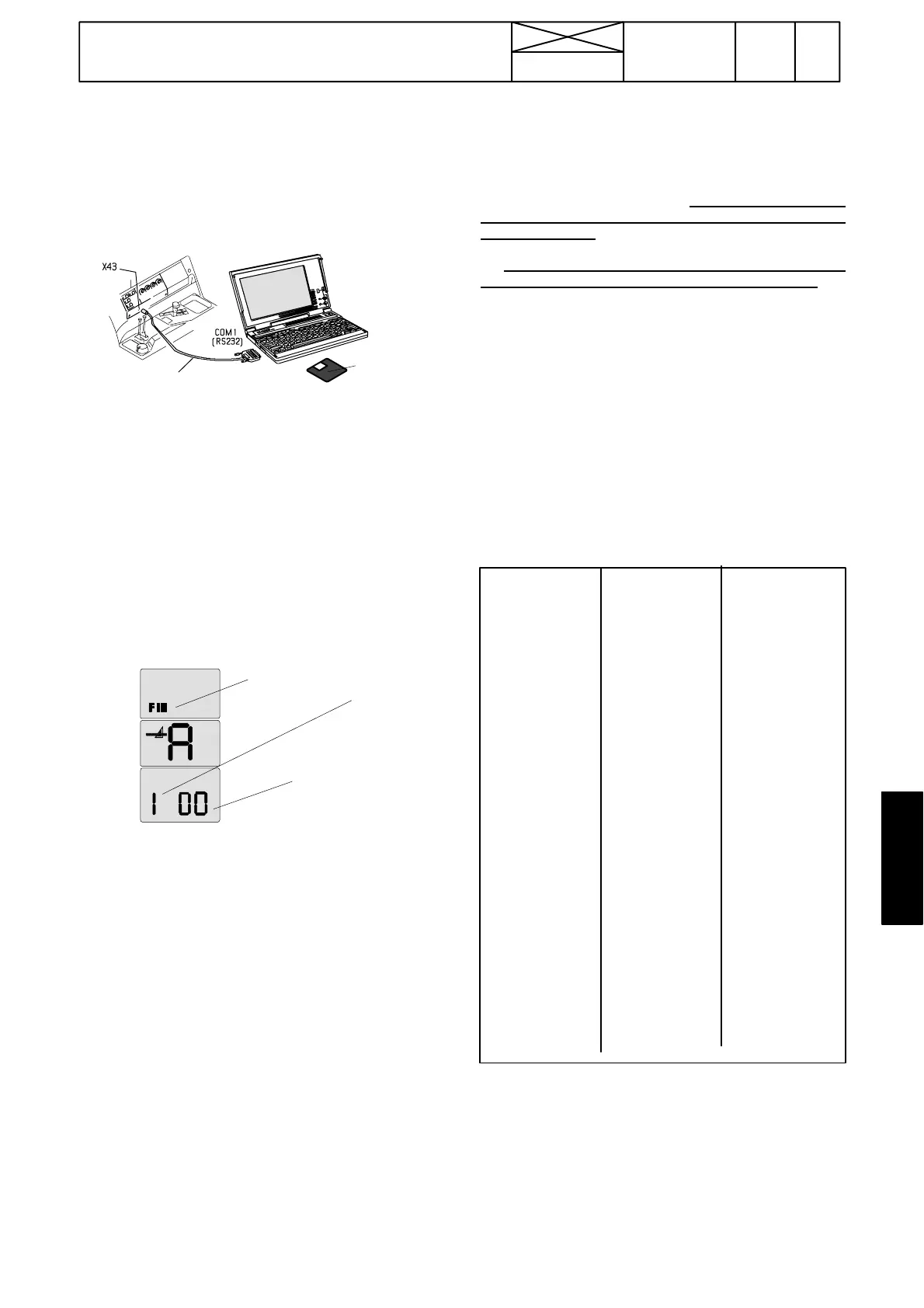

FIII=setting

mode sym-

bol

1=gas pe-

dal calibra-

ting mode

Blinking

00=calibration

can be done

7. When the gas pedal calibration has been selected and con-

firmed (1 is visible in the LH side segment),

digits 00 start to blink in the two RH side segments (2 Hz). This

indicates that the calibrating can be done.

8. Set the mechanical gears in neutral (engine at low idling).

Raise the engine revs evenly and gently with the throttle lever

up to max. revs taking about 10 seconds, however all the time

the revs must increase. When the max. revs have been re-

ached, wait about 3 seconds and press the HiShift button.

At which time the control unit reads values in the cal ibrating

points and saves them in to memory. Lower the low idling

speed. After the successful calibration digits 01 appear in the

two RH side segments. If the calibration is not successful, start

the calibration again and raise the revs slower once again du-

ring 12---15 seconds with the hand throt tle lever.

NOTE! If the calibration has failed (00 without blinking in the

two RH side segments), the values are not saved but the

earlier values remain valid. In this case the calibration must be

repeated.

IMPORTANT! The calibrating mode is left by switching the

current off.

9. After calibration is finished the calibration values will appear

on the laptop’s screen automatically, see Ta b l e 1 .Scrollthe

text on the screen if all values are not shown from the top. On

the top of table is the text, “pedal motor”

10. From the values can be seen all the pedal position values

for the control unit and the motor values in rpm. Selected va-

lues of the calibrat i on are below all values. Both all values and

selected values must be correct. If they are correct, an

in-

formation

“ Error0 ” appears, then the calibration is done cor-

rectly, see

Ta b l e 1 .

11. If the calibration has not been done correctly information

“ Error ”

appears and amount of the errors, see Ta b l e 2 . This

canhappenifallorselected pedal values do not increase

evenly. This means that if the value is decreasing or there are

the same value twice, the calibration has failed.

12. In table 3 is an example in which calibration appears to

be correct, because of the information “ Error 0 ”. But in the

last row, the value of the engine’s revs is lower than the earlier

value. This can cause DPS malfunctions. Do the calibration

again.

NOTE! Check always that pedal and engine values increase

evenly, although the information “ Error 0 ” appears. It is poss-

ible, that the computer does not find faults.

13. Do the gas pedal calibration again and make sure that

revs are rising evenly (without stop) during calibration.

Other possible faults listed in stage G and in page 370/24.

If “ PEDAL ” ---values do not increase evenly.

--- Check the sensor function in all measuring areas ( e.g. with

oscilloscope FLUKE 123)

--- Check, that the gas pedal is pressed evenly during the

wholecalibrationinthesamedirection.

If “ MOTOR ” ---values do not increase evenly.

--- Check, that the gas pedal is pressed evenly during the

whole calibration in the same direction. (the pressing can be

slowed a little towards the end).

--- Check the function of the engine speed sensor B11 in all

measuring areas.

Loader v0.4 4Mb-

Samples

pedal motor

233 851 rpm

249 934 rpm

267 1016 rpm

291 1104 rpm

335 1271 rpm

358 1360 rpm

383 1448 rpm

405 1529 rpm

431 1610 rpm

455 1697 rpm

477 1785 rpm

502 1868 rpm

527 1954 rpm

528 2035 rpm

530 2001 rpm

Selected

pedal motor

233 851 rpm

267 1016 rpm

313 1187 rpm

358 1360 rpm

405 1529 rpm

455 1697 rpm

502 1868 rpm

528 2035 rpm

530 2001 rpm

Error 0

Loader v0.4 4Mb-

Samples

Pedal Motor

312 869 rpm

327 950 rpm

344 1031 rpm

354 1115 rpm

371 1196 rpm

385 1279 rpm

401 1363 rpm

416 1444 rpm

433 1525 rpm

447 1605 rpm

465 1691 rpm

480 1777 rpm

499 1863 rpm

512 1944 rpm

497 1863 rpm

514 1952 rpm

534 2046 rpm

551 2127 rpm

567 2208 rpm

Selected

Pedal Motor

312 869 rpm

354 1115 rpm

385 1279 rpm

416 1444 rpm

447 1605 rpm

499 1863 rpm

497 1863 rpm

534 2046 rpm

567 2208 rpm

Error 1

Loader v0.4 4Mb-

Samples

Pedal Motor

311 878 rpm

341 960 rpm

356 1045 rpm

368 1125 rpm

377 1208 rpm

389 1290 rpm

414 1378 rpm

434 1465 rpm

451 1558 rpm

464 1641 rpm

473 1728 rpm

488 1817 rpm

530 1916 rpm

551 1996 rpm

563 2078 rpm

572 2161 rpm

580 2245 rpm

609 2335 rpm

Selected

pedal motor

311 878 rpm

368 1125 rpm

389 1290 rpm

434 1465 rpm

464 1641 rpm

488 1817 rpm

551 1996 rpm

572 2161 rpm

609 2335 rpm

Error 0

TABLE 1

TABLE 2

TABLE 3

pedal: gas pedal position motor: engine speed

Loading...

Loading...