---85---

I. Checks and adjustments

I. Checks and Adjustments

Check and adjustment instructions for the extra

equipment are in section K, after each extra equipment.

I 1. Engine

I 1.1. Bleeding fuel system

There should be no air in the fuel system to ensure that

the motor function is of maximum efficiency. The system

automaticly removes the small guantity of air which has

built up in the filters and injection pump. The fuel system

must be bled if any part of it has been removed or if the

tractor has run out of fuel during driving so that air has

entered the system. Bleed the fuel system as follows:

I 1.1.1. Bleeding distributor pump system of

air

69---88

1

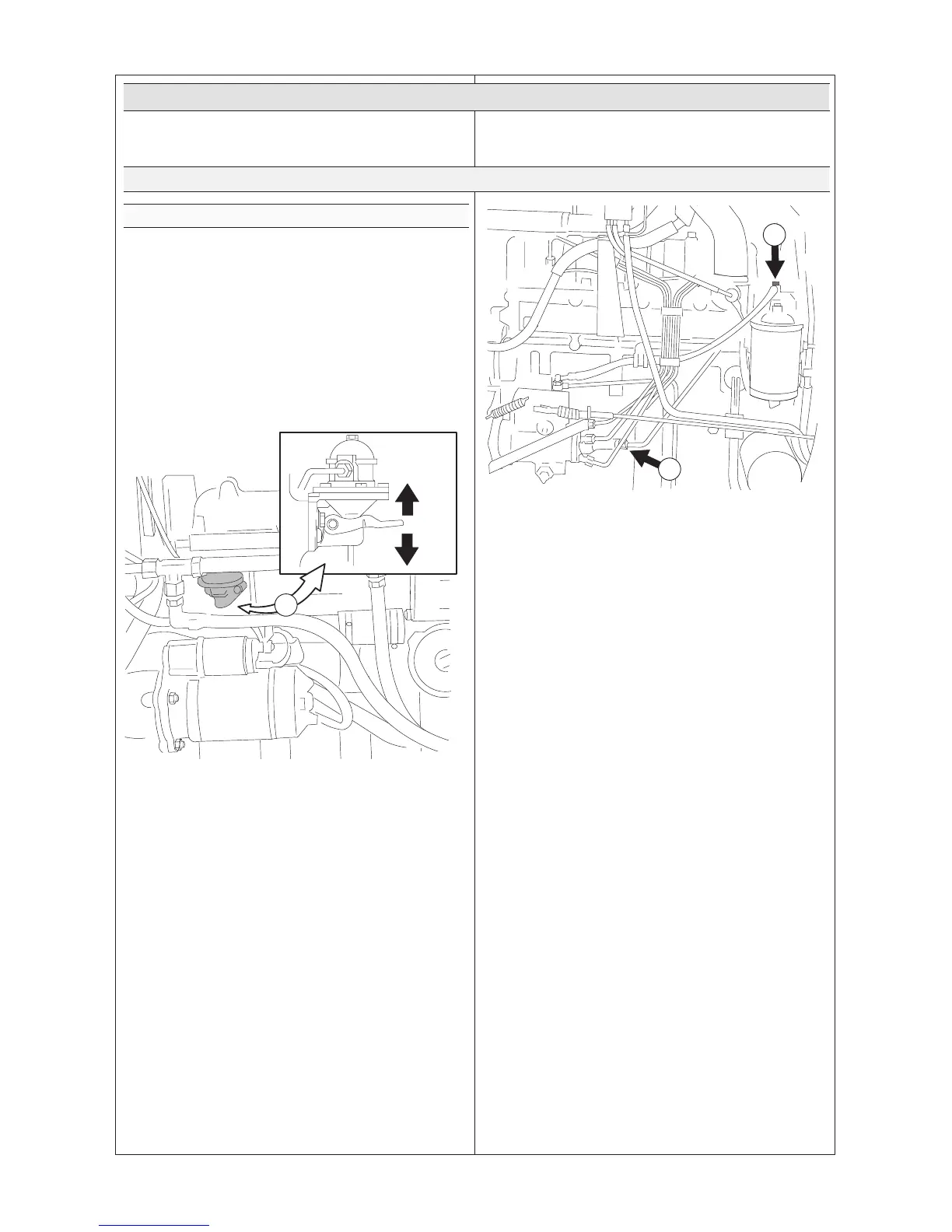

1. Pump by hand the lever (1) on the fuel pump. If

pumping feels ineffective, turn the engine a little, so the

camshaft turns away from the line of the pump arm.

69---89

3

2

2. Open the bleed screw (2). Operate the hand pump (1)

until there are no air bubbles in the fuel which runs out.

Tighten screw (2).

NOTE! Do not open the bleed screw above the

prefilter, as it is in the suction side.

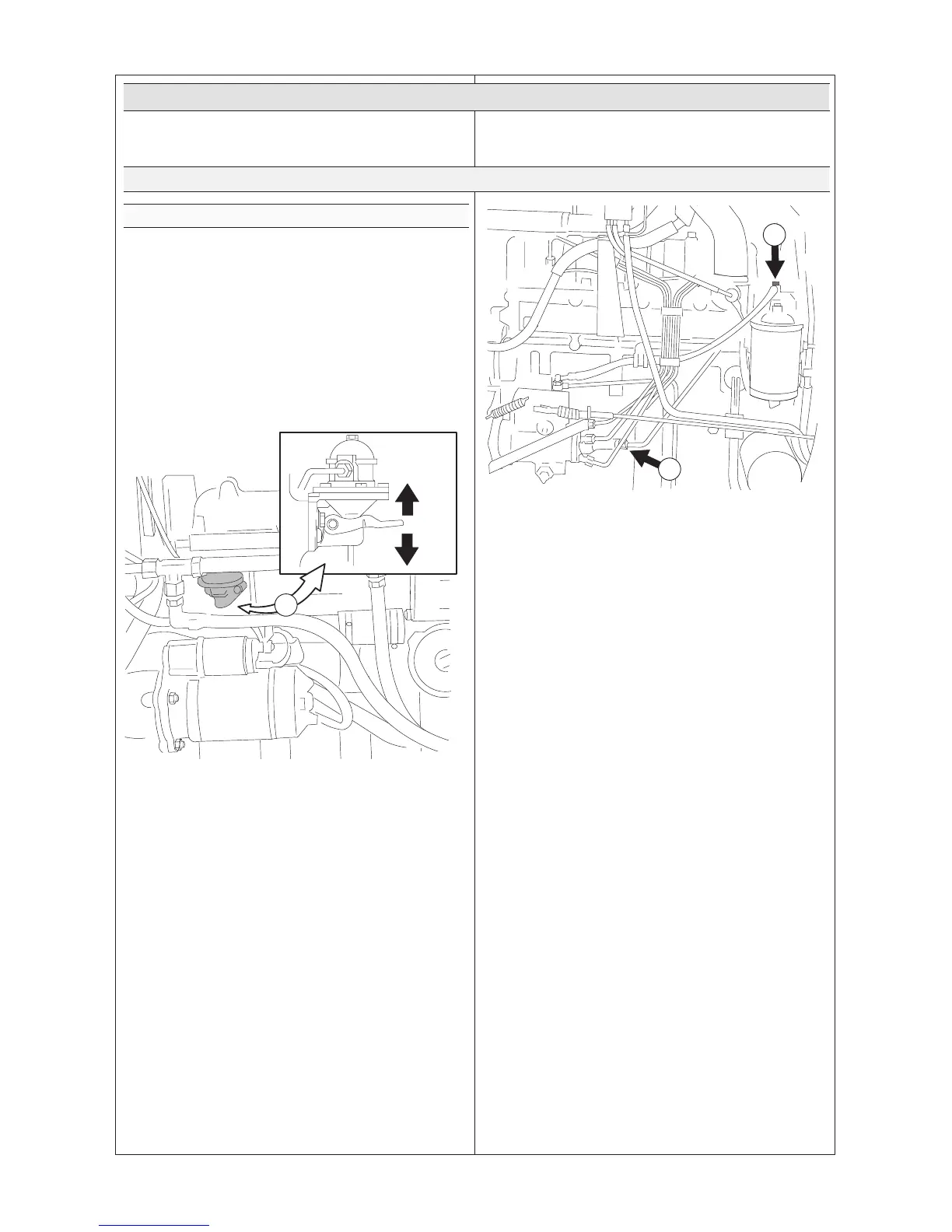

3. Continue pumping and open the bleeding union (3)

which is in the middle of the rearside of the pump, until

there are no air bubbles in the fuel which runs out.

Tighten the union.

CAUTION: When the pump is empty of fuel, do not

leave the tractor switched on for a long time, as there

is a stop solenoid in the injection pump which could

be damaged.

After bleeding the system as detailed above, the fuel

pump will fill up once the starter motor starts to turn the

engine.

4. Start the engine and check that there are no leaks.

Loading...

Loading...