8

SYSTEM CALIBRATION

System calibration must be carried out after installation

and during the annual function test. Calibration means

programming all data for the system’s various settings

into the electronic unit’s memory.

WARNING!

Never calibrate while the engine is running.

Two separate calibrations must be performed: system

calibration and control calibration.

System calibration

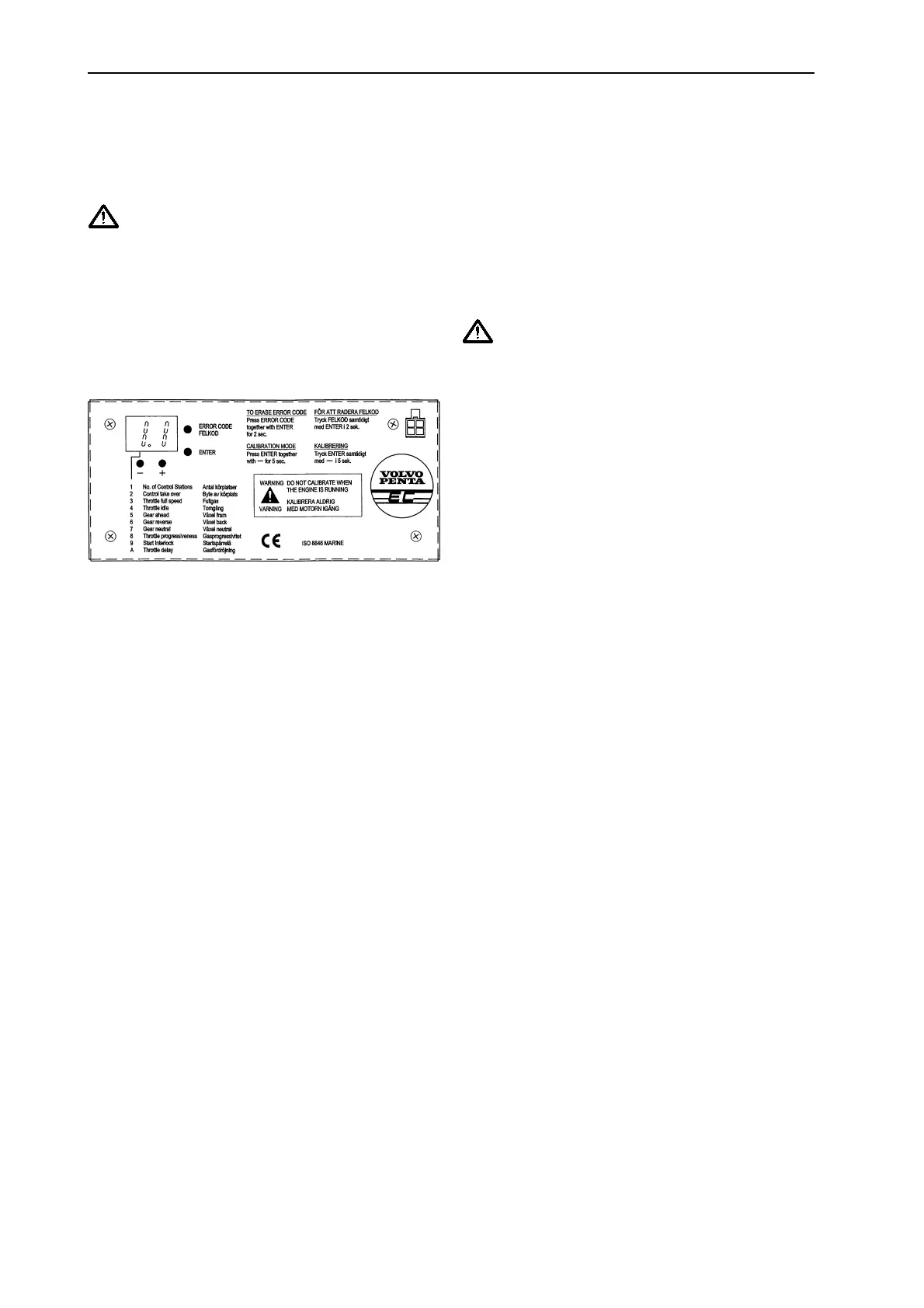

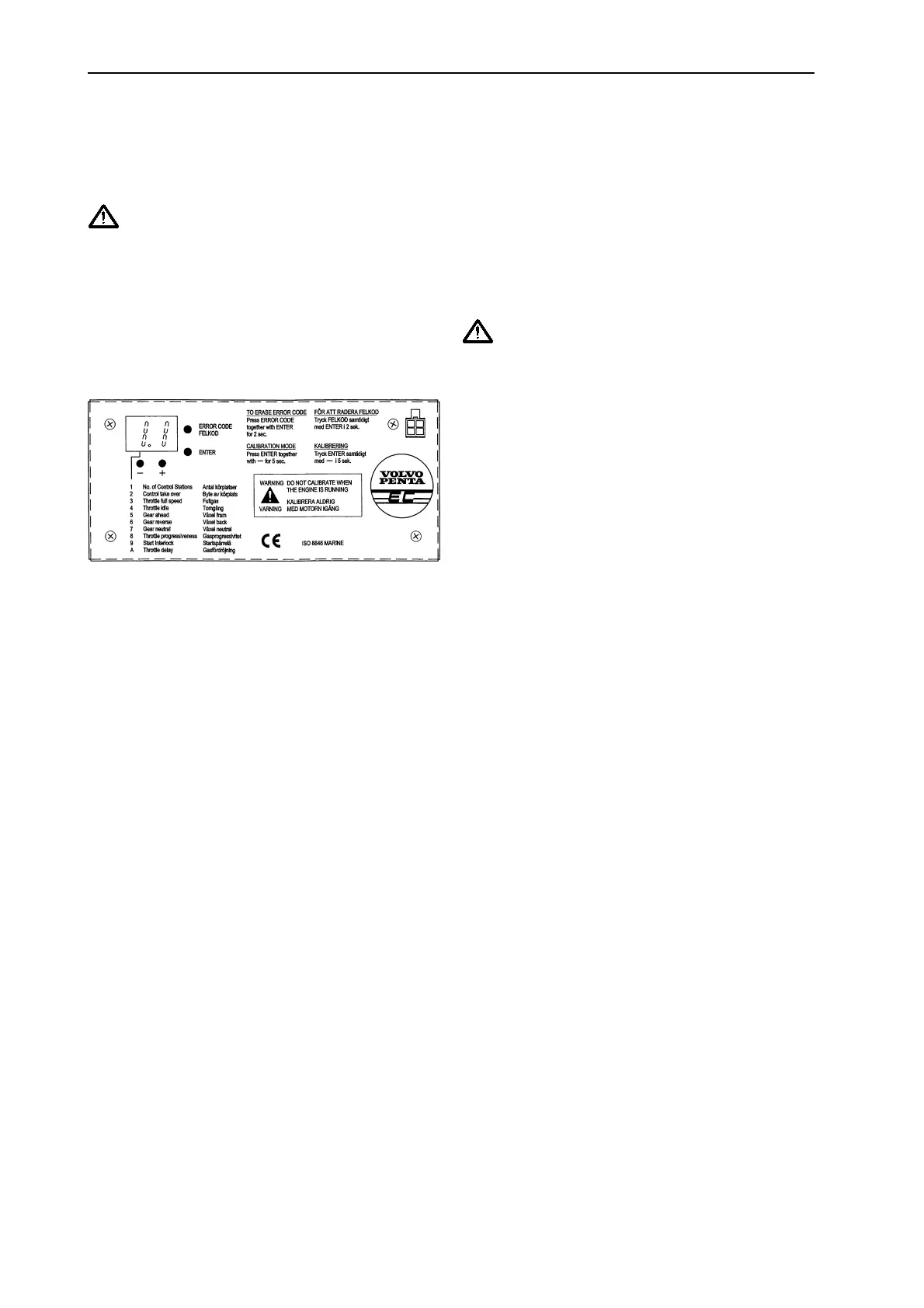

Use the buttons and display on the electronic unit to

perform system calibration. Detach the drive unit cover.

FIG. 6

The first figure on the display indicates which function is

being set. See the figure above. The second states the

current setting of the function in question.

Find out whether the engine’s throttle is pulling or

pushing and which is forward and reverse on the

reverse gear before starting the calibration.

An optional 4 m extension cord can be ordered to

facilitate system calibration. With the extension, the

electronic unit can be detached from the drive unit and

then employed as a “Remote control” when setting

throttle and gear functions.

When setting the stroke length of the mechanical cables

to match the movements of the throttle and gear arm, it

can be adjusted using the (+) and (-) buttons on the

electronic unit. (-) = actuator in, (+) = actuator out.

NB! When adjusting the actuators, take care so as not

to set them too tightly against their respective

mechanical stops. Should the actuators begin to

make noise when set, they are too tight and will

need to be “backed off” (within 10 seconds);

otherwise, the actuator will jam. Should the

actuators jam anyway, follow instructions on page

15.

Starting system calibration

a. Switch off all voltage to the system and ignition

and wait 10 seconds.

b. Switch on the Main pos. (+) and ignition but not

the backup pos.(+).

c. Enter the program by holding down the Enter

button and the (-) button at the same time for 5

seconds. Release, and the display lights up.

1. Setting the number of controls

The display now shows 1.1, which means that one

control can be connected. To select two controls, press

the (+) button once so that 1.2 appears on the display.

For three controls, press the (+) button again so that 1.3

appears.

2. Setting “station changeover” options

Press Enter and 2.0 appears, which means that

changeover is only possible in neutral. Press (+) so that

2.1 appears on the display = changeover underway is

now programmed.

WARNING!

When performing a changeover at speed, the

active operating position must not be left

unmanned.

3. Setting full throttle position

Press Enter. A value between 3.3 and 3.7 will appear on

the display.

3.3 = actuator fully retracted.

3.7 = actuator fully extended. Adjust the actuator

position using the (+) and (-) buttons.

4. Setting idle position

Press Enter. A value between 4.3 and 4.7 will appear on

the display.

4.3 = actuator fully retracted.

4.7 = actuator full extended. Adjust using the (+) and (-)

buttons.

5. Setting forward gear position

Press Enter. A value between 5.3 and 5.7 will appear on

the display.

5.3 = actuator fully retracted.

5.7 = actuator fully extended. Adjust using the (+) and (-)

buttons.

6. Setting reverse gear position

Press Enter. A value between 6.3 and 6.7 will appear on

the display.

6.3 = actuator fully retracted.

6.7 = actuator fully extended. Adjust using the (+) and (-)

buttons.

7. Setting neutral gear position

Press Enter. A value between 7.3 and 7.7 will appear on

the display.

7.3 = actuator fully retracted.

7.7= actuator fully extended. Adjust using the (+) and (-)

buttons.

8. Setting throttle progression (5 different curves)

Press Enter. 8.0, 8.1, 8.2, 8.3 or 8.4 will appear on the

display. Each figure combination indicates a specific

throttle curve. See diagram page 9. Select throttle curve

using the (+) and (-) buttons. Normal standard curve =

8.1.

9. Setting starting lock function

Press Enter. 9.0 or 9.1 will appear on the display. Using

the (+) and (-) buttons, select 9.0 if no starting lock relay

is fitted or 9.1 if a starting lock relay has been installed.

User Instructions

Loading...

Loading...