Watlow PM PLUS™ 6 • 87 • Chapter 8: Features

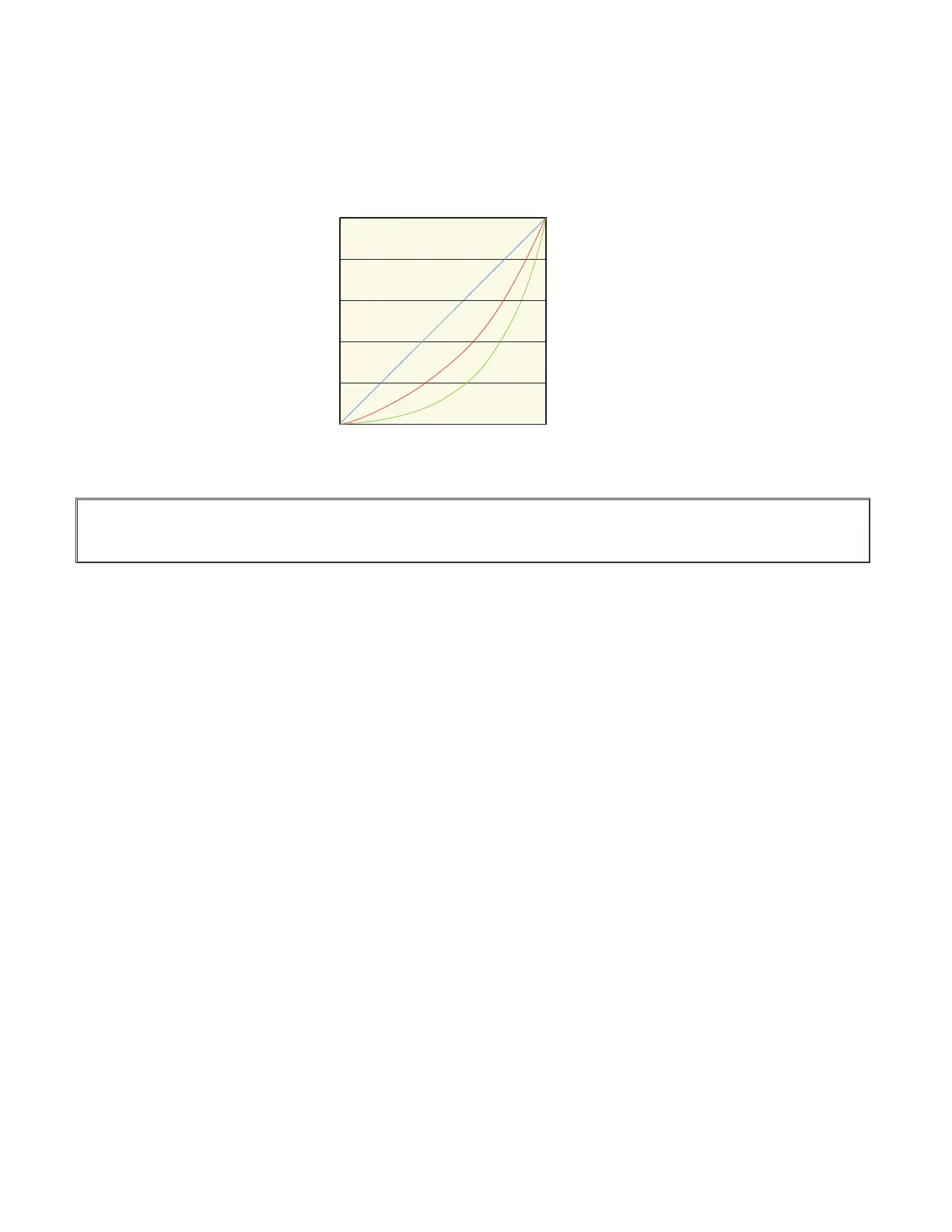

Cool Output Curve

A nonlinear output curve may improve performance when the response of the output device is nonlinear. If a

cool output uses one of the nonlinear curves a PID calculation yields a lower actual output level than a linear

output would provide. These output curves are used in plastics extruder applications: curve A for oil-cooled

extruders and curve B for water-cooled extruders.

To configure a cool output curve, go to Operations — Setup — Control Loop and select Cool Output Curve.

Resetting a Tripped Limit

Applicable on Integrated Limit models. Check your product label to confirm the configuration code shows L or M

in the 9th digit: PM _ _ _ _ _ - _ [L,M] _ _ _ _ _.

On Limit models, output 4 is a Form A (normally open) Mechanical Relay and it is internally tied to the limit

function. When the limit is in a safe state the internal coil for this relay is energized, and the relay will be

closed. When a condition causes the limit to trip, the internal coil de-energizes, causing the relay to latch

open. When the condition that caused the limit to trip is within the limit range, plus the hysteresis value; the

relay remains latched open until manually reset by an operator.

Reset a Tripped Limit (Use one of these four methods)

1. When at the Home Page, and a Limit condition occurs; then "Attention Limit" will appear. It will also state

"Press Home to Request Clear".

2. Set Source Function A to the device that will reset the limit (Digital I/O or Function Key).

3. Use a field bus protocol, i.e., Modbus

®

, EtherNet/IP™, etc. and write a value of zero to the associated

address (navigate to the Operations List — and look for Clear Limit under the Limit Menu to find

appropriate address).

4. Cycle the power to the controller.

Actual Output Power

0

20

40

60

80

100

Linear

Curve 1

Curve 2

Linear

Curve A

Curve B

Loading...

Loading...