Watlow PM PLUS™ 6 • 91 • Chapter 8: Features

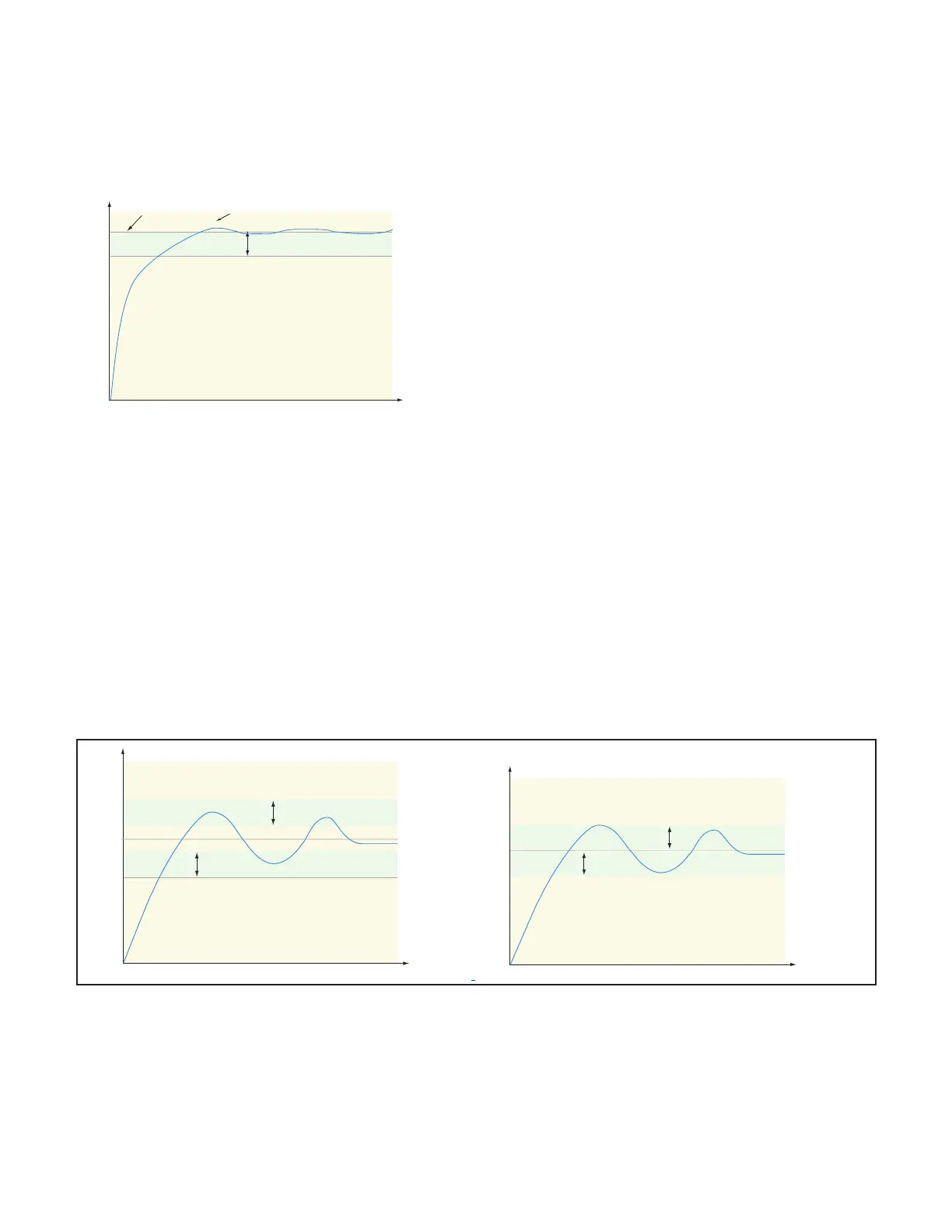

Proportional, Integral and Derivative (PID) Control

Use derivative (rate) control to minimize the overshoot in a PI-controlled system. Derivative (rate) adjusts

the output based on the rate of change in the temperature or process value. Too much derivative (rate) will

make the system sluggish. Adjust the derivative with Time Derivative

td (Operations Page, Loop Menu).

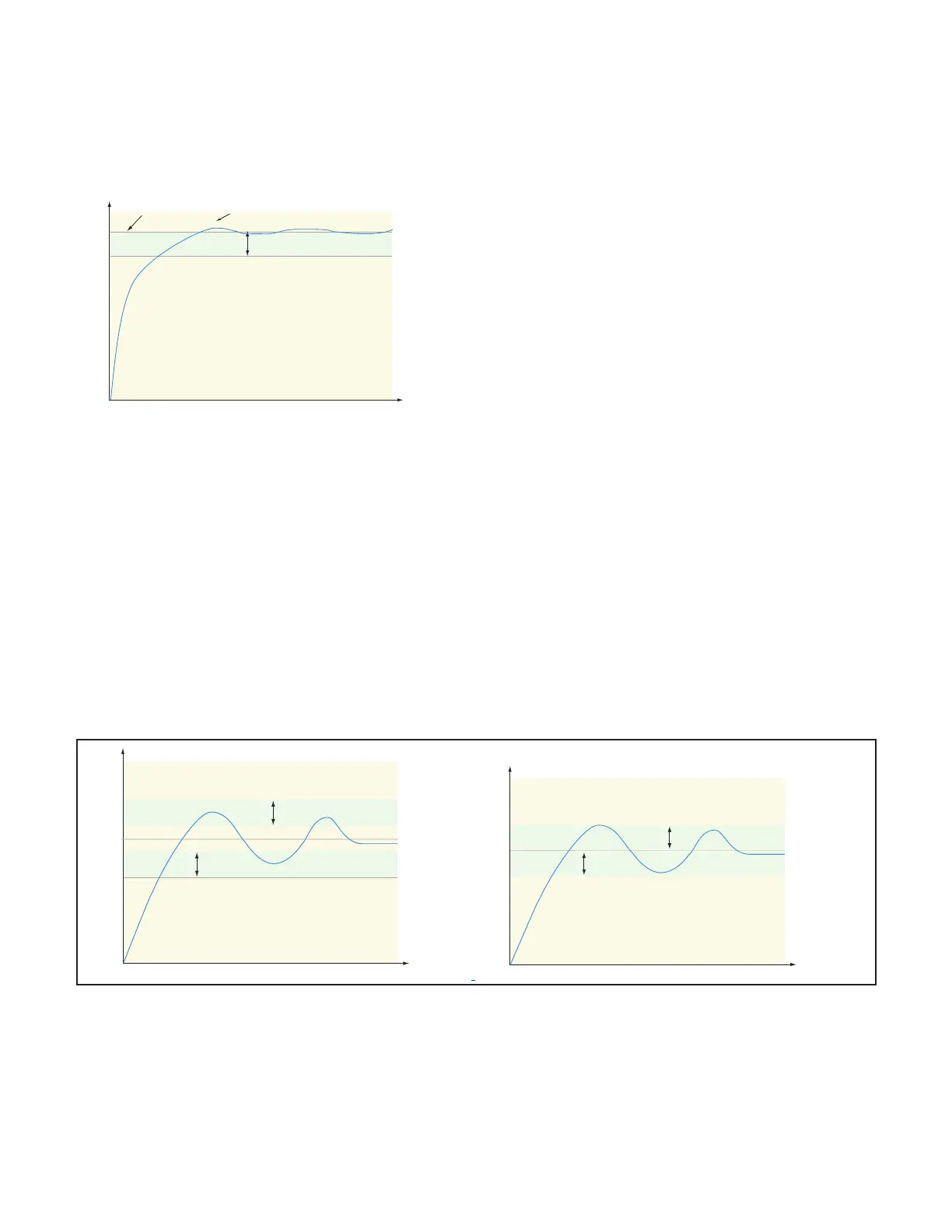

Dead Band

In a PID application the dead bands above and below the set point can save an application’s energy and wear

by maintaining process temperature within acceptable ranges.

Proportional action ceases when the process value is within the dead band. Integral action continues to

bring the process temperature to the set point. Using a

positive dead band value keeps the two systems from

fighting each other.

When the dead band value is zero, the heating output activates when the temperature drops below the set

point, and the cooling output switches on when the temperature exceeds the set point.

Time

Temperature

Positive Dead Band

Set Point

Heat Output Active

Cool Output Active

Time

Temperature

Zero Dead Band

Set Point

Heat Output Active

Cool Output Active

When the dead band value is a negative value, both heating and cooling outputs are active when the tem-

perature is near the set point.

Go to Operations — Setup — Control Loop — Deadband to adjust.

Time

Temperature

PID Control

Set Point

Reduced Overshoot

Proportional Band

Loading...

Loading...