Watlow PM PLUS™ 6 • 94 • Chapter 8: Features

Differential Control

The PM can be configured for Differential Control with two inputs and enhanced firmware. After configuring

the appropriate inputs and their associated internal functions Differential Control allows the PM to drive an

output based on the difference between those analog inputs. See

Application examples.

Ratio Control

The PM PLUS can be configured for Ratio control with two inputs and enhanced firmware, especially useful

in applications that mix materials. Ratio control is commonly used to ensure that two or more flows are kept

at the same ratio even if the flows are changing. See

Application examples.

Duplex Control

Certain systems require that a single process output controls both heating and cooling outputs. A PM PLUS

with a process output can function as two separate outputs.

With a 4 to 20mA output the heating output, for instance, will operate from 12 to 20mA (0 to +100%) and

the cooling outputs will operate from 12 to 4mA (0 to -100%). In some cases this type of output is required

by the device, such as a three-way valve that opens one way with a 12 to 20mA signal and opens the other

way with a 4 to 12mA signal. This feature reduces the overall system cost using a single output to act as two

outputs.

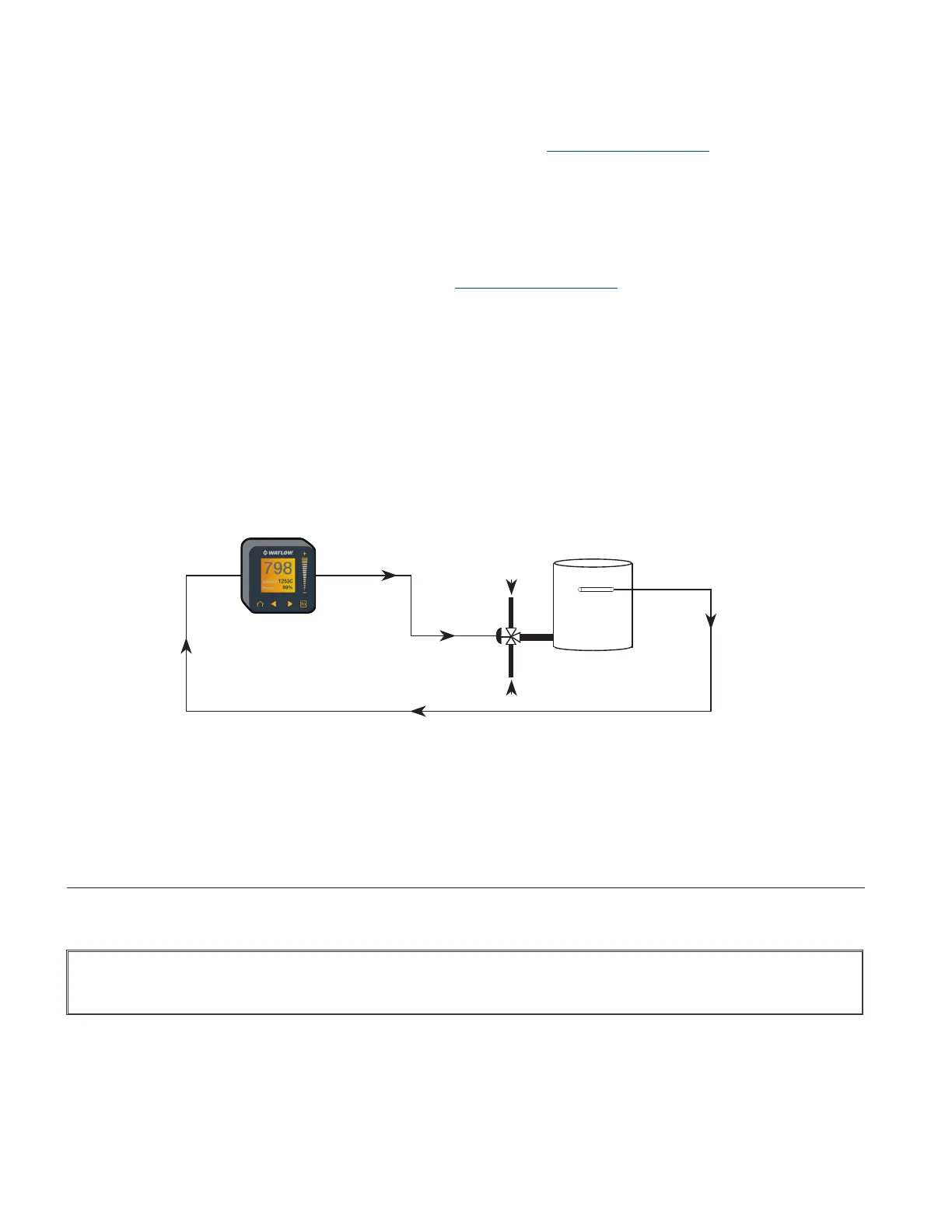

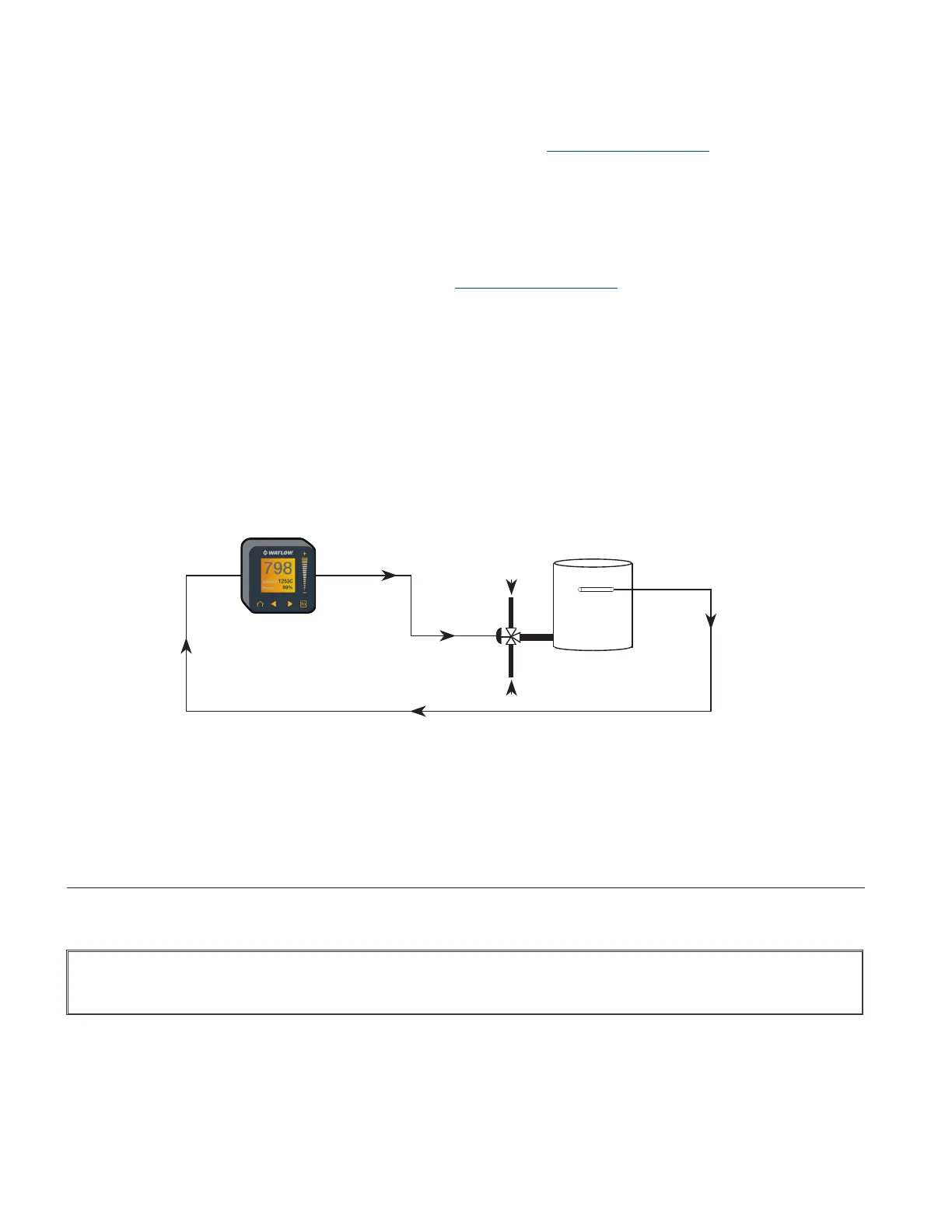

Motorized Valve Control

A motorized valve is used is to regulate the flow of fluid which in turn impacts the loop process value. A

valve is opened or closed by closing contacts to drive the value in the intended direction.

Timer Function

Applicable on models with a countdown timer. Check your product label to confirm the configuration code shows

T in the 4th digit: PM _ T _ _ _ - _ _ _ _ _ _ _.

hot water

cold water

temperature

transmitter

Fluid S ample Cont ainer

Input 1 Output 1

Loading...

Loading...