28

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.3 Wiring and Fuses for

Power and Grounding

ATENTION!

Provide at least 0.25 m (10 in) spacing between low voltage wiring

and drive/motor cables. For instance: PLC’s, temperature monitoring

devices, thermocouples, etc.

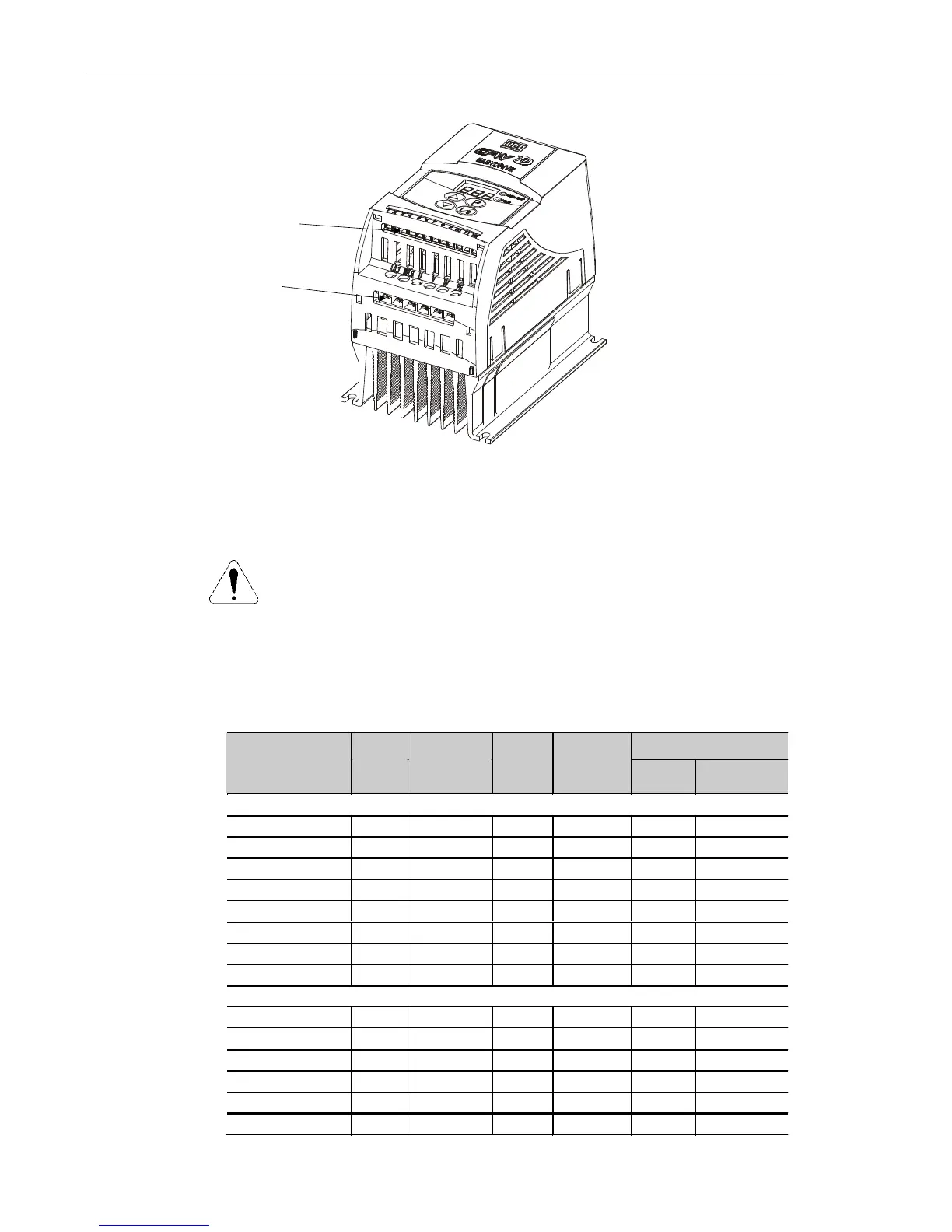

Table 3.3 presents minimum cable diameter and circuit breaker rating

for the CFW-10. Tightening torque shall be as indicated in table 3.4.

All power wiring (cooper) shall be rated for 70 ºC minimum.

Table 3.3 - Recommended wire cross-section and circuit-breakers - use (70 ºC) copper

wiresonly

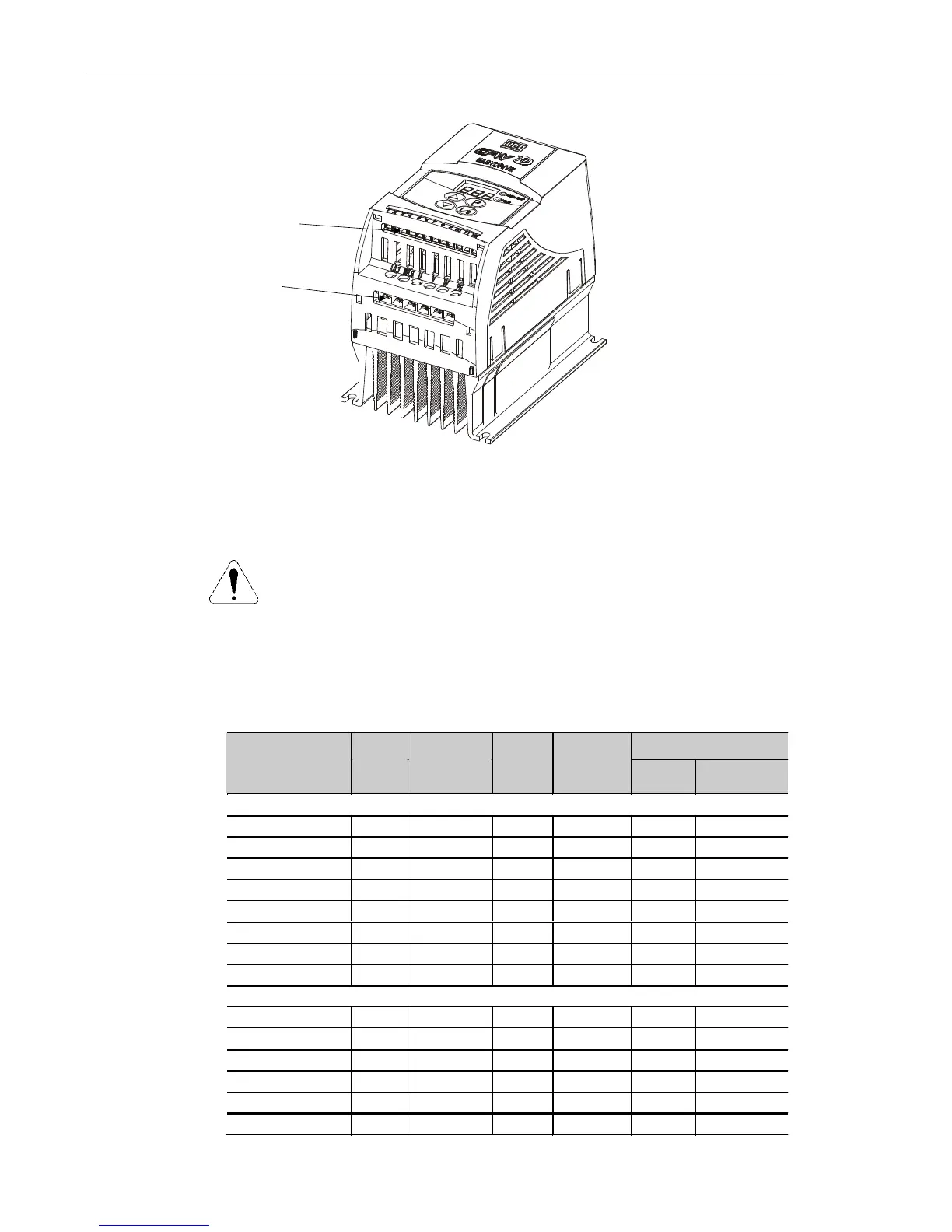

3.2.2 Location of the Power,

Grounding and Control

Connections

Control XC1

Power

Figure 3.5 - Location of the Power and Control Connections

Circuit-Breaker

Rated Inverter

Current [A]

Motor

Wiring

[mm²]

Grounding

Wiring

[mm²]

Power

Cables

[mm²]

Maximum

Cables

[mm²]

Current

WEG

Model

SINGLE-PHASE MODELS

1.6 (200-240 V ) 1.5 2.5 1.5 2.5 6 MPW 25-6.3

1.6 (110-127 V ) 1.5 2.5 1.5 2.5 10 MPW25-10

2.6 (200-240 V ) 1.5 2.5 1.5 2.5 10 MPW25-10

2.6 (110-127 V ) 1.5 2.5 2.5 2.5 16 MPW25-16

4.0 (200-240 V ) 1.5 2.5 1.5 2.5 16 MPW25-16

4.0 (110-127 V ) 1.5 4.0 2.5 4.0 20 MPW25-20

7.3 (200-240 V ) 2.5 4.0 2.5 4.0 20 MPW25-20

10.0 (200-240 V) 2.5 4.0 4.0 4.0 25 MPW25-25

THREE-PHASE MODELS

1.6 (200-240 V ) 1.5 2.5 1.5 2.5 2.5 MPW 25-2.5

2.6 (200-240 V ) 1.5 2.5 1.5 2.5 6.3 MPW 25-6.3

4.0 (200-240 V ) 1.5 2.5 1.5 2.5 10 MPW25-10

7.3 (200-240 V ) 2.5 4.0 2.5 4.0 15 MPW25-15

10.0 (200-240 V) 2.5 4.0 4.0 4.0 20 MPW25-20

15.2 (200-240 V) 4.0 4.0 4.0 4.0 25 MPW25-25

Loading...

Loading...