38

CHAPTER 3 - INSTALLATION AND CONNECTION

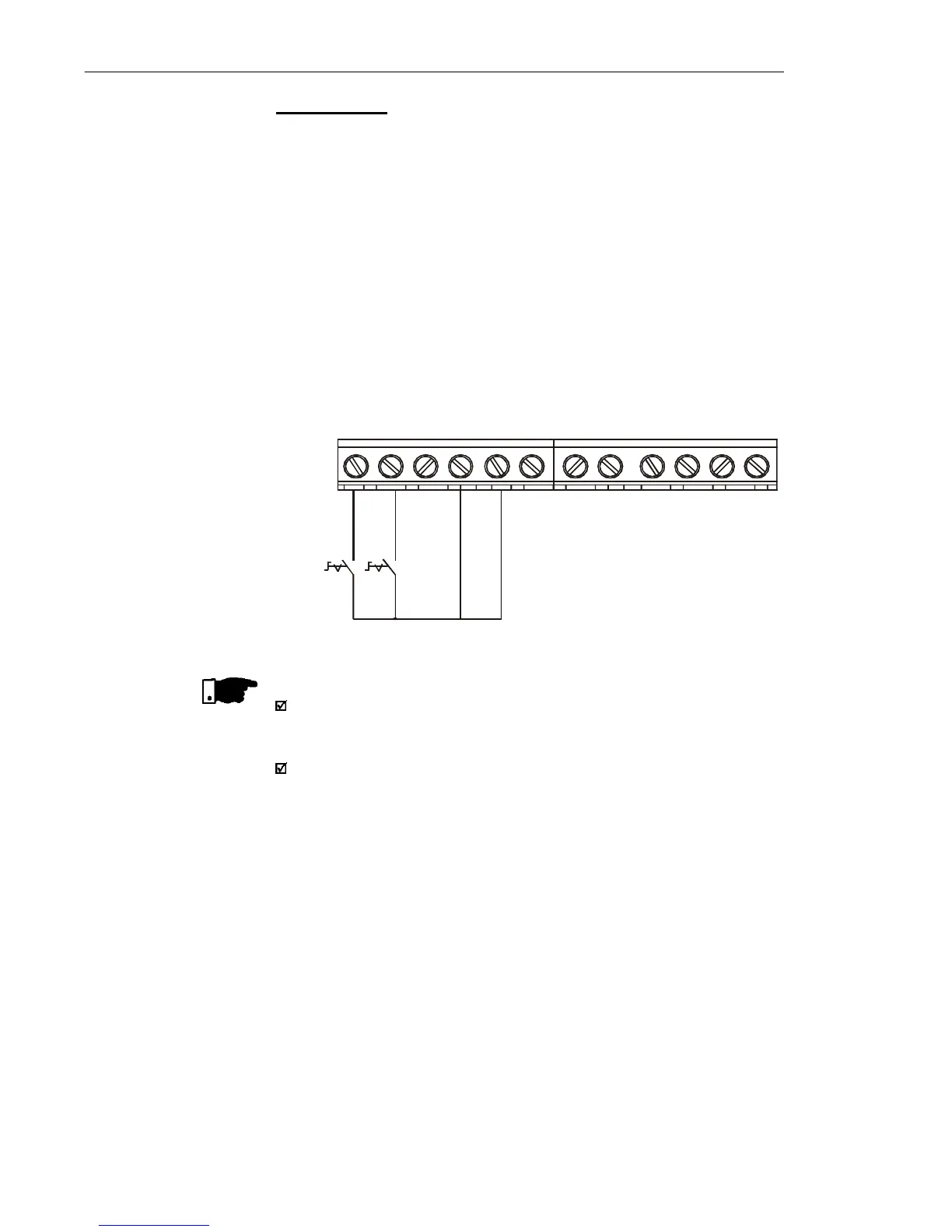

Connection 4

Enabling of the FWD/REV function:

Set DI1 to Forward Run : P263 = 9

Set DI2 to Reverse Run: P264 = 10

Make sure the inverter commands are via terminals, i.e., set

P229 = 1 to local mode.

NOTE!

The speed reference can be realized via Analog Input AI1 (as in

connection 2), via keypad (HMI), or via any other source (see

description of parameters P221 and P222).

When a line fault occurs in this connection mode with switch S1 or

switch S2 is closed, the motor will be enabled automatically as

soon as the line is re-restablished.

Figure 3.12 - Wiring for Connection 4

DI4 - No Function / Ramp

Enabling

S1 open: Stop

S1 closed: Forward Run

S2 open: Stop

S2 closed: Reverse Run

DI1 - Forward Run

DI2 - Reverse Run

DI3 - Local/Remote

GND

AI1 (0.4 to 20 mA)

GND

AI1 (0 to 10 Vdc)

+10 Vdc

NC

Common

NO

S2S1

1 2 3 4 5 6 7 8 9 10 11 12

The CFW-10 inverter series was designed considering all safety and

EMC (ElectroMagnetic Compatibility) aspects.

The CFW-10 units do not have an intrinsic function until connected

with other components (e. g. a motor). Therefore, the basic product is

not CE marked for compliance with the EMC Directive. The end user

takes personal responsibility for the EMC compliance of the whole

installation. However, when ins talled acc ording to the

recommendations described in the product manual and including the

recommended filters and EMC measures the CFW-10 fulfill all

requirements of the (EMC Directive 89/336/EEC) as defined by the

EN61800-3 "EMC Product Standard for Adjustable Speed

Electrical Power Drive Systems - specific standard for variable

speed drives.

The conformity of the complete CFW-10 series is based on tests

performed on sample models. A Technical Construction File (TCF)

was prepared, checked and approved by a Competent Body.

3.3 European EMC

Directive -

Requirements

for Conforming

Installations

Loading...

Loading...