98

CHAPTER 7 - DIAGNOSTICS AND TROUBLESHOOTING

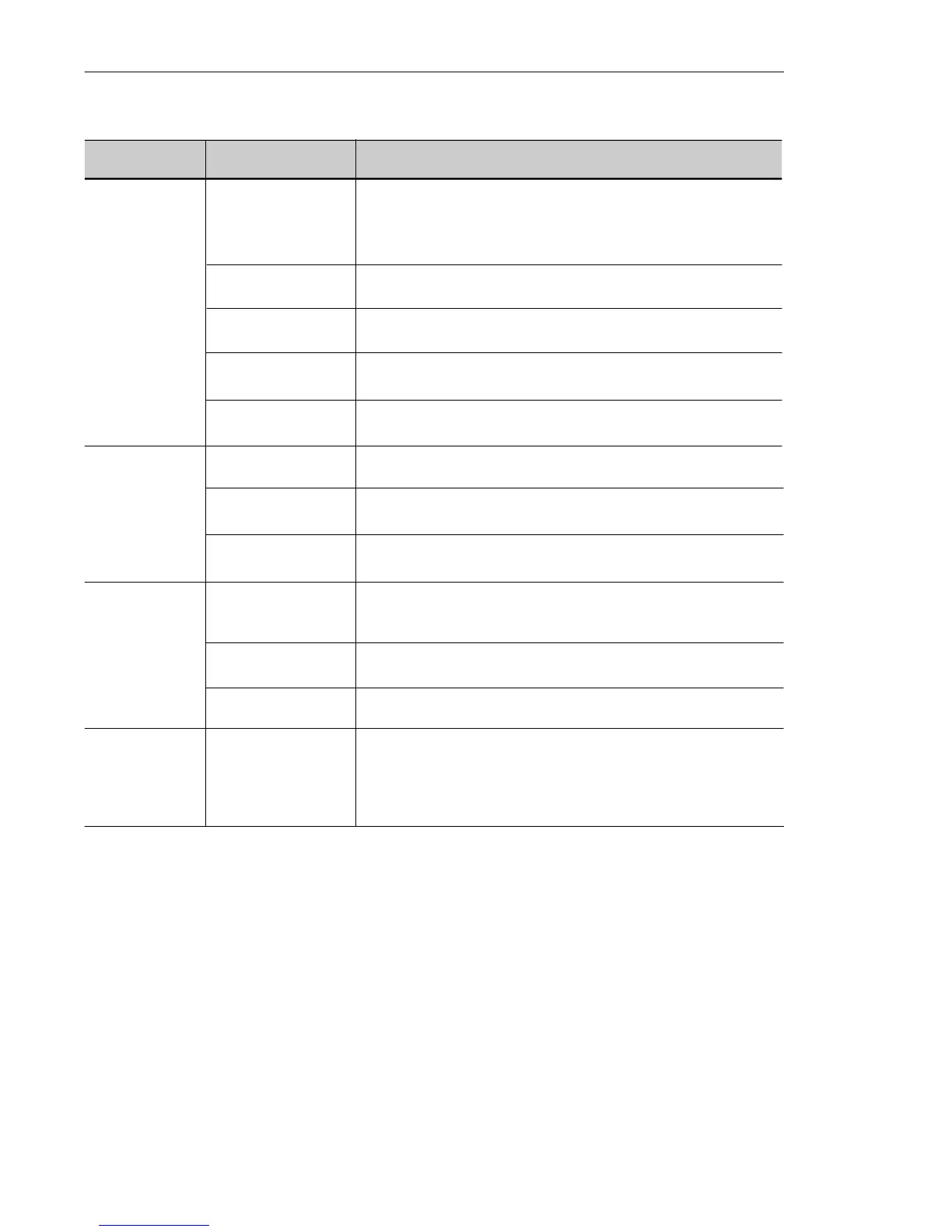

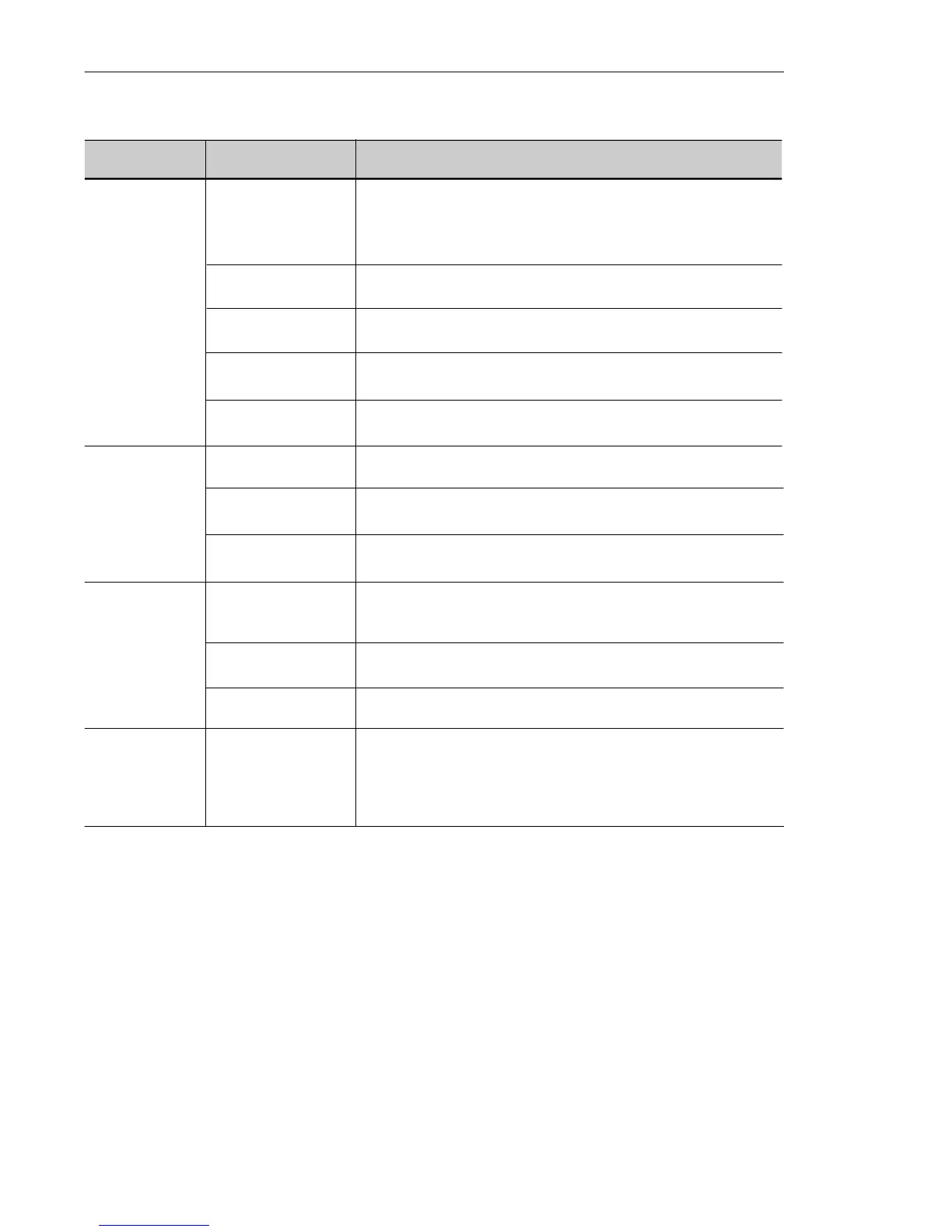

7.2 TROUBLESHOOTING

PROBLEM

POINT TO BE

CORRECTIVE ACTION

CHECKED

Motor does Incorrect wiring 1.Check the power and the control connections. For example,

not run the digital inputs DIx programmed for Start/Stop or General Enable

or No External Fault must be connected to GND (pin 5 of the

control connector XC1).

Analog reference 1.Check if the external signal is properly connected.

(if used) 2.Check the status of the speed potentiometer (if used).

Incorrect programming 1.Check if the parameters are properly programmed for the

application.

Fault 1.Check if the inverter has not been disabled due to detected fault

condition (refer to table above).

Motor stall 1.Reduce the motor load.

2.Increase P169 or P136/P137.

Motor speed Loose connections 1.Disable the inverter, switch OFF the power supply and tighten all

oscillates connections.

Defective speed 1.Replace the defective speed potentiometer.

potentiometer

Variation of the external 1.Identify the cause of the variation.

analog reference

Motor speed Programming error 1.Check if the contents of P133 (minimum frequency)

too high or (reference limits) and P134 (maximum frequency) are according to the motor

too low and the application.

Signal of the 1.Check the control signal level of the reference.

reference control 2.Check the programming (gains and offset) at P234 to P236.

Motor nameplate 1.Check if the used motor meets the application requirements.

data.

Display OFF Power supply 1.The power supply must be within the following ranges:

200-240 V models: - Min: 170 V

- Max: 264 V

110-127 V models: - Min: 93 V

- Max: 140 V

Loading...

Loading...