49

CHAPTER 4 - KEYPAD (HMI) OPERATION

Reference Backup

The last frequency reference, set by the keys the and ,

is stored when inverter is stopped or the AC power is removed,

provided P120 = 1 (reference backup active is the factory default). To

change the frequency reference before inverter is enabled, you must

change the value of the parameter P121.

and

Motor speed (frequency) setting: these keys are enabled for speed

setting only when:

The speed reference source is the keypad (P221 = 0 for LOCAL

Mode and/or P222 = 0 for REMOTE Mode);

The following parameter content is displayed: P002, P005 or P121.

Parameter P121 stores the speed reference set by these keys.

When pressed, it increases the speed (frequency) reference.

When pressed, it decreases the speed (frequency) reference.

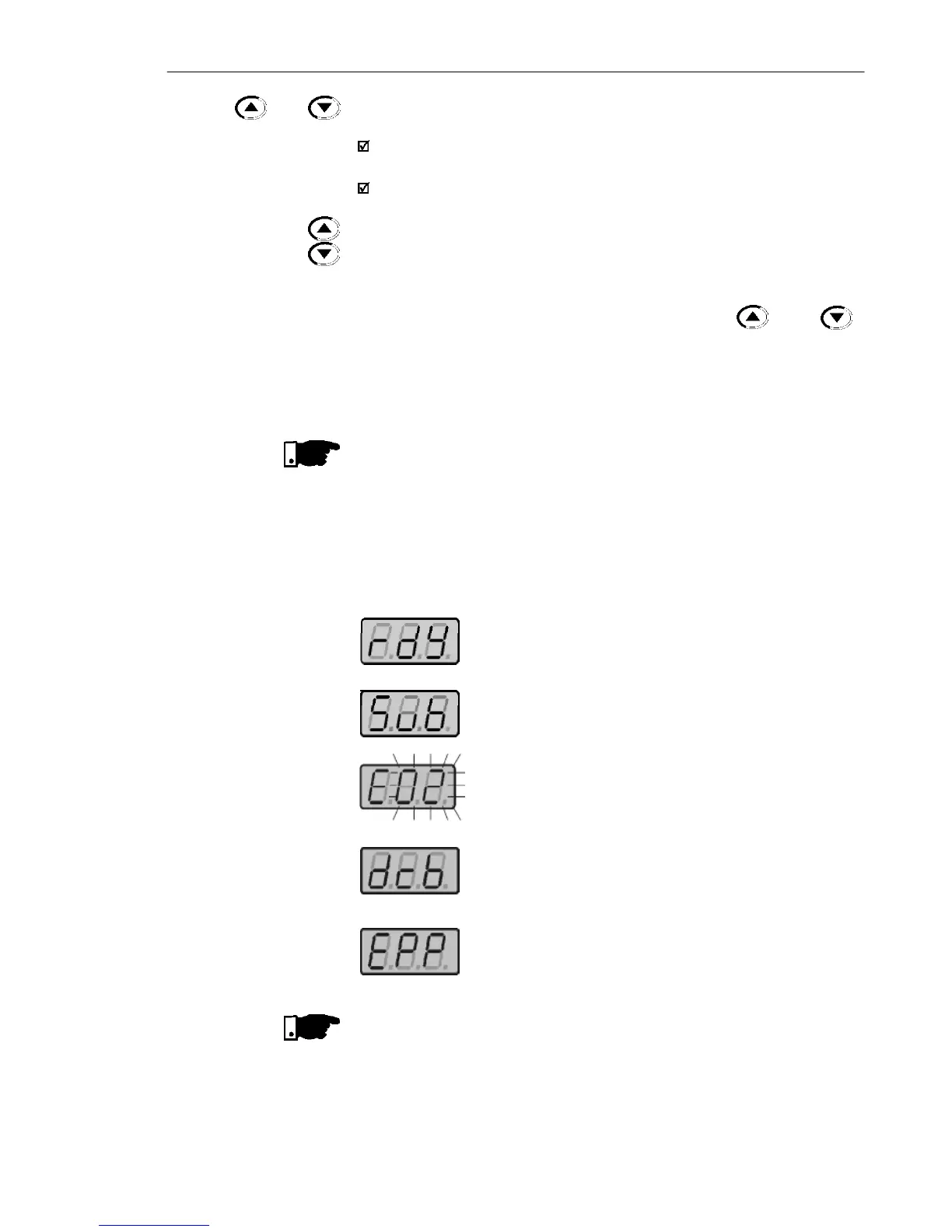

Inverter status:

Inverter is READY to be started.

Line voltage is too low for inverter operation

(undervoltage condition).

Inverter is in a Fault condition. Fault code is flashing

on the display. In our example we have the fault

code E02 (refer to chapter 7).

Inverter is applying a DC current on the motor (DC

braking) according to the values programmed at

P300, P301 and P302 (refer to chapter 6).

Inverter is running self-tuning routine to identify

parameters automatically. This operation is

controlled by P204 (refer to chapter 6).

4.2.2 Inverter Status -

HMI Display

NOTE!

On CFW-10 Plus version, the motor frequency setting function is made

through the HMI potentiometer. However, it is possible to set the mo-

tor frequency through the keys since P221/P222 parameters were

programmed.

NOTE!

Besides the fault conditions, the display also flashes when the inverter

is in overload condition (refer to chapter 7).

Loading...

Loading...