128

CFW-08 OPTIONS AND ACCESSORIES

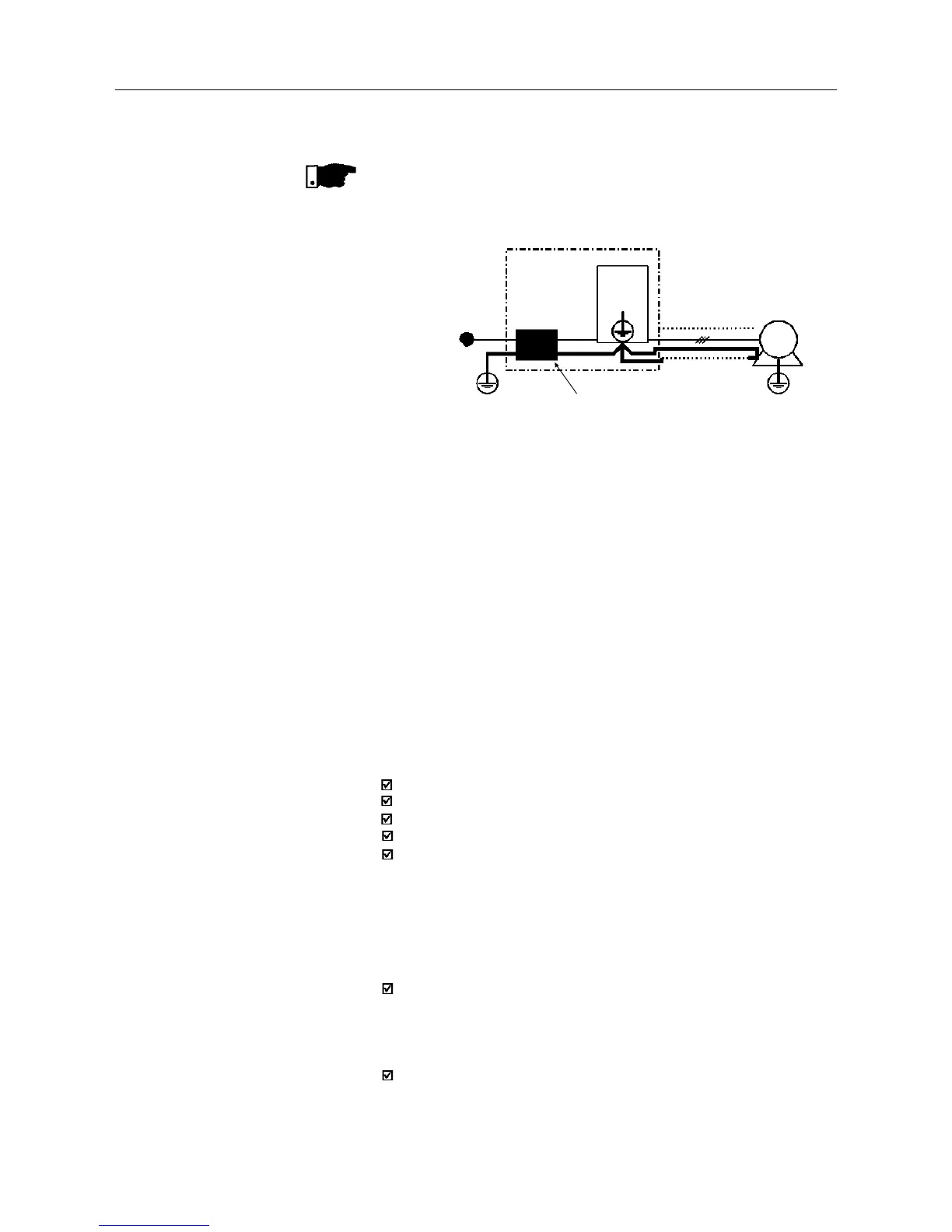

Power

Supply

Ground

Filter

CFW-08

Driving Panel

Conduit or

Shielded Cable

Motor

Motor Ground

(frame)

PE

PE

Figure 8.20 - Connection of the external RFI filter - Class B

8.16 LINE REACTOR

Due to the input circuit characteristic, common to the most inverters

available on the market, consisting of a diode rectifier and a capacitor

bank, the input current (drained from the power supply line) of inverters is

a non sinusoidal waveform and contains harmonics of the fundamental

frequency (frequency of the power supply - 60 or 50Hz).

These harmonic currents circulate through the power supply line and

cause harmonic voltage drops which distort the power supply voltage of

the inverter and other loads connected to this line. These harmonic currents

and voltage distortions may increase the electrical losses in the

installation, overheating the components (cables, transformers, capacitor

banks, motors, etc.), as well as lowering the power factor.

The harmonic input currents depend on the impedance values that are

present in the rectifier input/output circuit.

The installation of a line reactor reduces the harmonic content of the

input current, providing the following advantages:

increasing the input power factor;

reduction of the RMS input current;

reduction of the power supply voltage distortion;

increasing the life of the DC link capacitors.

reduction of the overvoltage transients that may occur in the power

supply line.

8.16.1 Application Criteria

In a general manner, the CFW-08 series inverters can be connected

directly to the power supply line without line reactors. But in this case,

ensure the following:

To ensure the inverter expected life, a minimum line impedance

that introduces a voltage drop as shown in table 8.3, as a function of

the motor load, is recommended. If the line impedance (transformers

+ wirings) is lower than these values, it is recommended to use line

reactor(s).

When it is necessary to add a line reactor to the system, it is

recommended to size it considering a 2 to 4% voltage drop (for

nominal output current). This pratice is results in a compromise between

motor voltage drop, power factor improvement and harmonic current

distortion reduction.

Install it as close as

possible to the

inverter

NOTE!

For installations that must meet the European standards refer to item 3.3.

Loading...

Loading...