131

CFW-08 OPTIONS AND ACCESSORIES

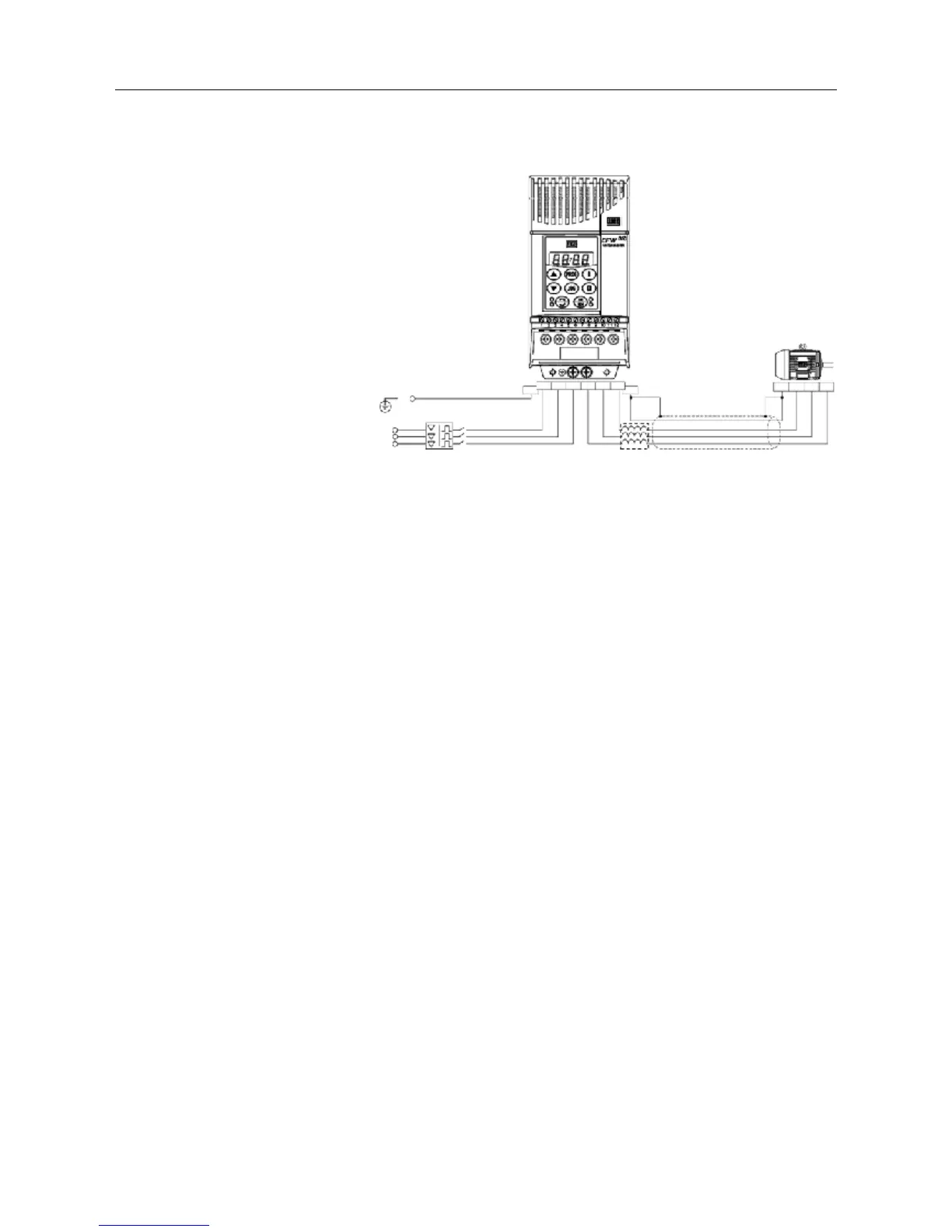

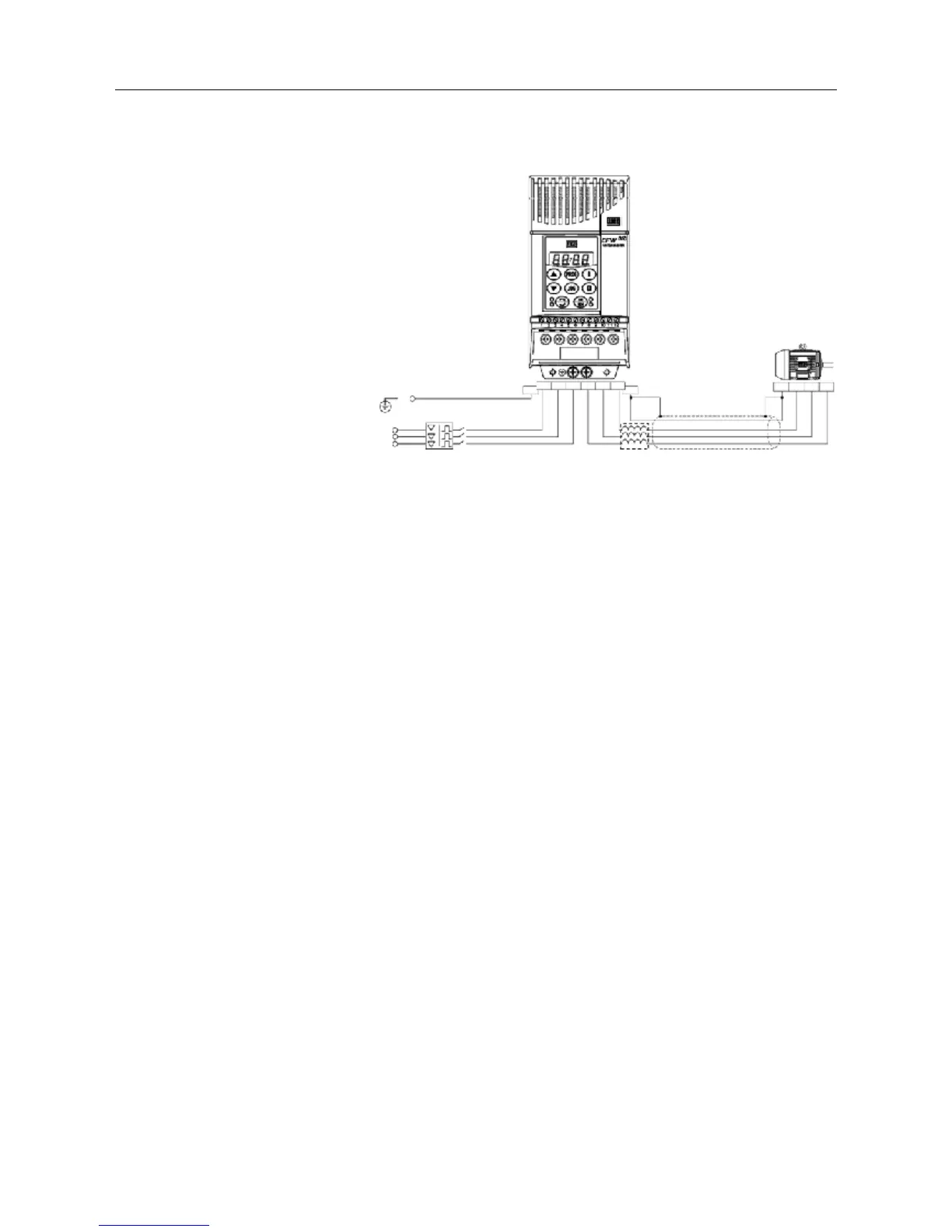

Figure 8.22 - Load Reactor Connection

8.18 DYNAMIC BRAKING

The dynamic braking is used where short deceleration times are required

or where high inertia is present.

For the correct sizing of the braking resistor, application data such as,

deceleration time, load inertia, braking duty cycle must be considered.

In any case, the rms current capacity and the maximum peak current

must be considered.

The maximum peak current defines the minimum permitted ohmic value

for the braking resistor. Refer to table 8.4.

The DC link voltage level for the actuation of the dynamic braking is as

follows:

Inverter supplied with 200...240V: 375Vcc

Inverters supplied with 380...480V: 750Vcc

R

S

T

PE

PE

RSTUVW

U

V

W

8.18.1 Resistor Sizing

The braking torque, that can be obtained through the frequency inverter,

without using the dynamic braking module, varies from 10 to 35% of the

rated motor torque. During the deceleration process, the kinetic energy of

the load is regenerated into the inverter DC link. This energy loads up the

capacitors by increasing the DC link voltage. When this energy is not

fully dissipated, it may generate a DC link overvoltage trip (E01) and

disabling the inverter.

To obtain higher braking torques, the use of dynamic braking is

recommended where the excess of the regenerated energy is dissipated

in a resistor mounted externally to the inverter. The braking resistor is

defined according to the deceleration time, load inertia and resistive torque.

In most cases, a resistor with an ohmic value as indicated on the table

below and a power rating of 20% of the driven motor can be used.

Use wire type or tape type resistors with suitable insulation to withstand

the instantaneous current peaks.

For critical applications with very short braking times, high inertia loads

(ex.: centrifuges) or with very short and frequent duty cycles, contact

WEG to define the most suitable resistor.

PE

DISCONNECTING

SWITCH

PE

LOAD

REACTOR

SHIELD

Loading...

Loading...