55

START-UP

4.3.2 Start-up

Operation Via Terminals -

Control Mode:

Linear V/F (P202=0)

Connections are according to Figures 3.4 and 3.12.

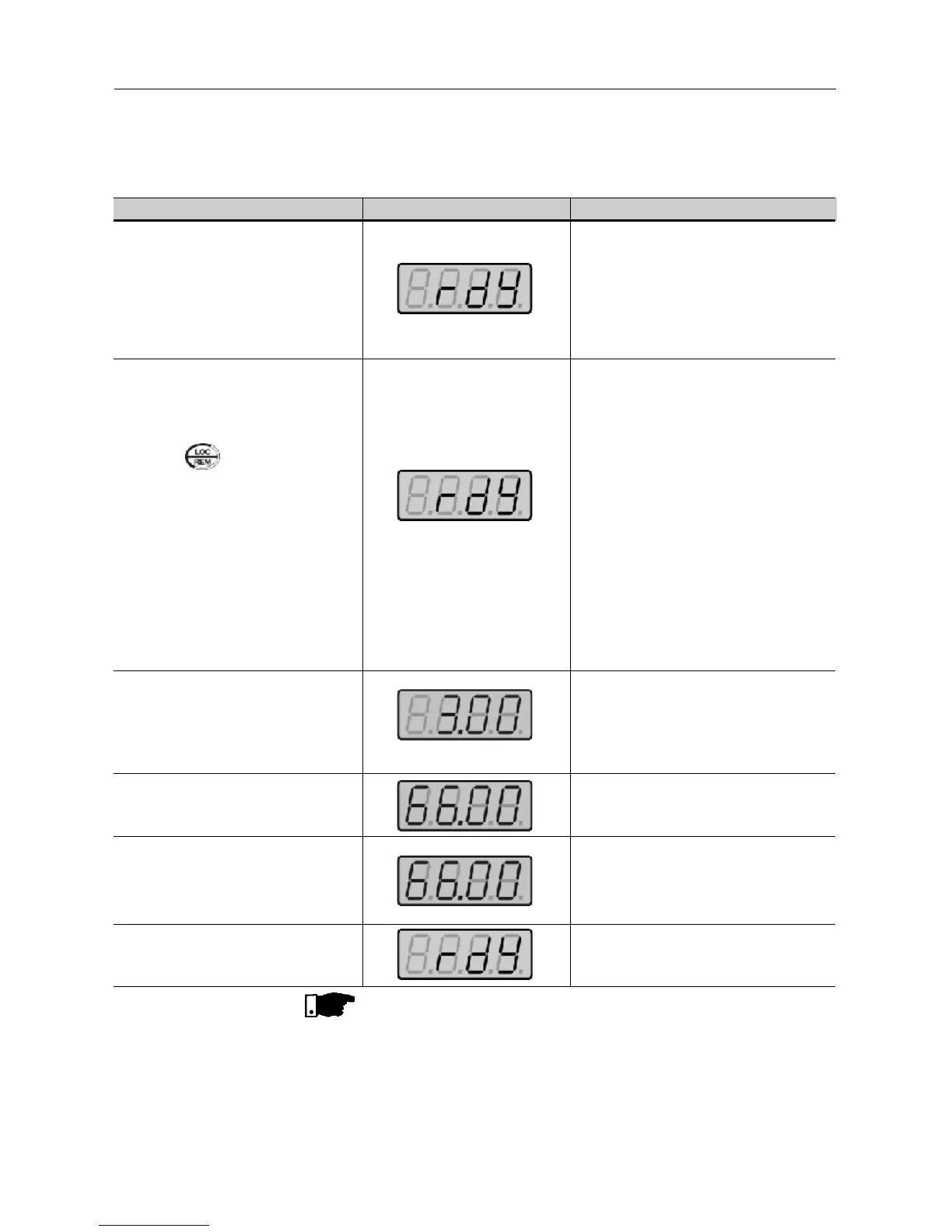

ACTION HMI DISPLAY DESCRIPTION

See Figure 3.12

Switch S1 (FWD / REV)=open

Switch S2 (Reset)=open

Switch S3 (Start/Stop)=open

Potentiometer R1 (Ref.)=totalzly CCW

Power-up inverter

Press the key

This procedure is not necessary when

inverters were delivered dummy panel,

since it will be automatically in remote

mode.

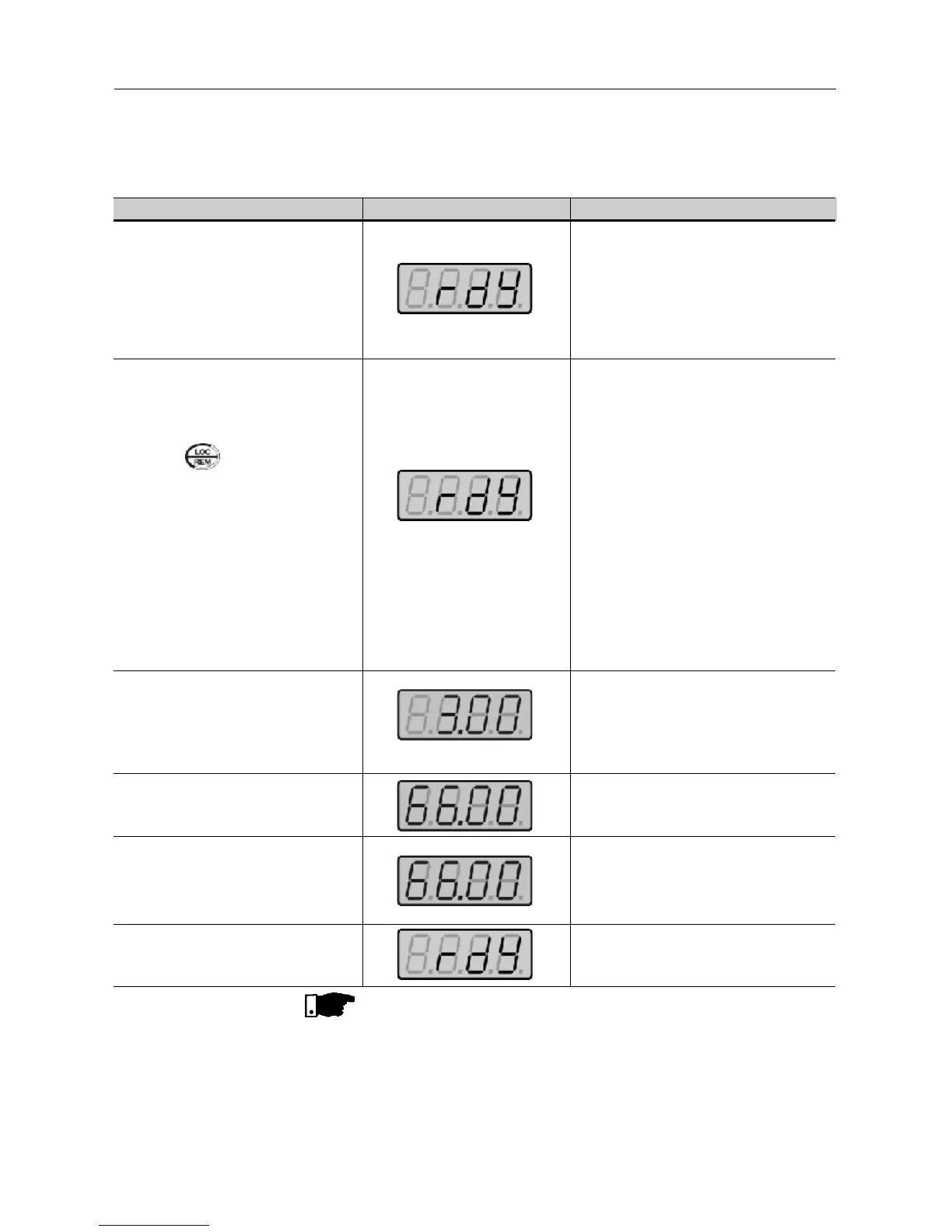

Close S3 – Start/Stop

Turn potentiometer totally CW.

Clse S1 – FWD / REV

Open S3 – Start / Stop

Inverter is ready to be operated.

Led LOCAL switches OFF and led

REMOTE switches ON. Control and

Reference are are switched to REMOTE

(via terminals).

To maintain inverter permanently in

REMOTE mode, set P220 = 1.

Note: If the inverter is switched off and

afterwards switched on, it will now

operate in local mode because P220=2

(factory setting). This setting means that

the local/remote selection source is via

keypad and the default mode (that is the

mode when the inverter is switched on)

is local. For further information see

description of P220 in Chapter 6.

Motor accelerates from 0Hz to 3Hz* (min.

frequency), CW direction

(1)

* 90rpm for 4-pole motor

The frequency reference is given by the

potentiometer R1.

Motor accelerates up to the the maximum

frequency (P134 = 66Hz)

(2)

Motor decelerates

(3)

down to 0 rpm (0Hz),

reverses the direction of rotation (CW ⇒

CWW) accelerating back up to the

maximum frequency (P134 = 66Hz).

Motor decelerates

(3)

down to 0 rpm.

NOTES!

(1) If the direction of roation of the motor rotation is not correct, switch off

the inverter. Wait 10 minutes to allow a complete capacitor discharge

and the swap any two wires at the motor output.

(2) If the acceleration current becomes too high, mainly at low frequencies,

set the torque boost (IxR compensation) at P136.

Increase/decrease the content of P136 gadually until you obtain an

operation with constant current over the entire frequency range.

For the case above, refer to Parameter Description in Chapter 6.

(3) If E01 fault occurs during deceleration, increase the deceleration time

at P101 / P103.

Loading...

Loading...