53

START-UP

4.3 START-UP

4.3.1 Start-up

Operation via Keypad

(HMI)- Type of Control:

Linear V/F(P202=0)

Connections according to Figure 3.4.

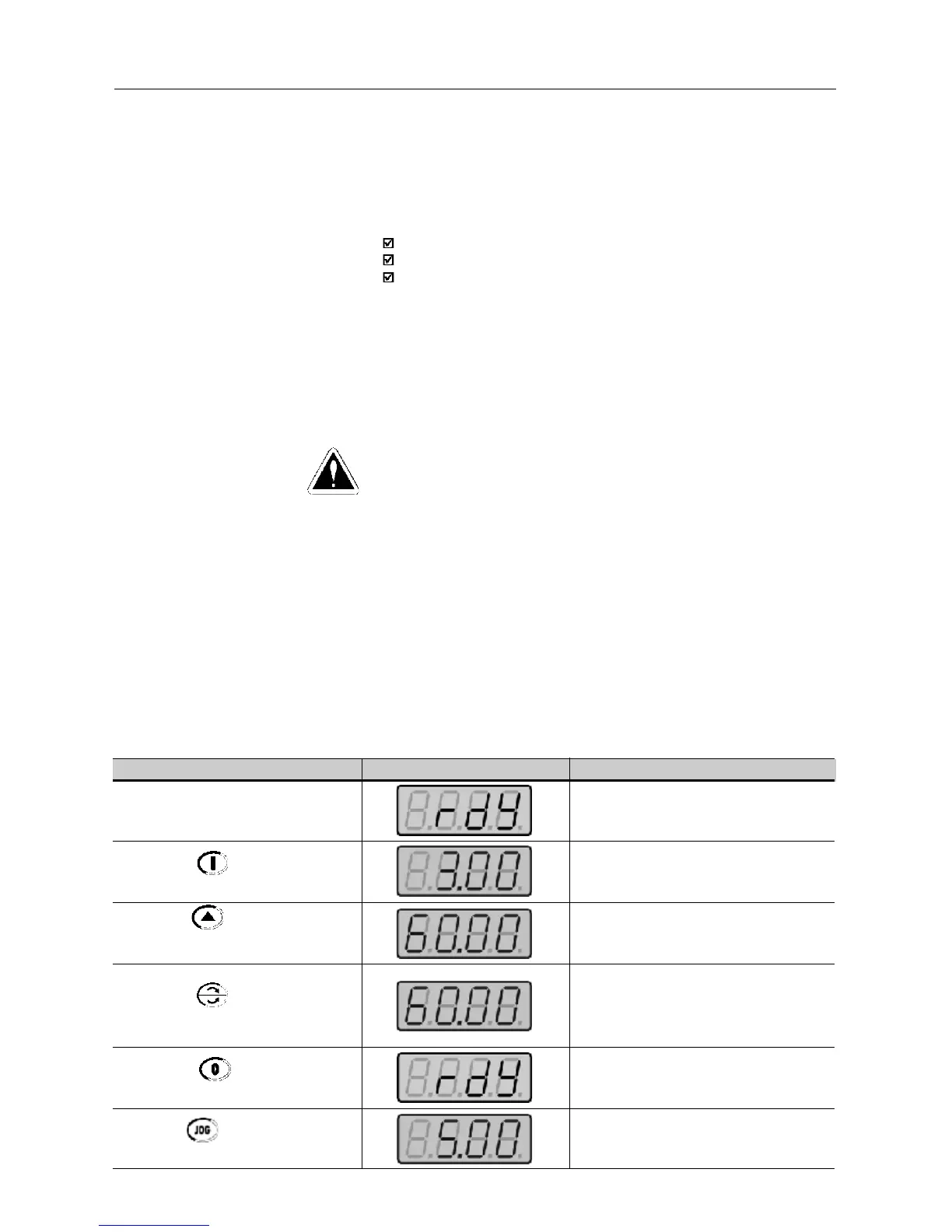

ACTION HMI DISPLAY DESCRIPTION

Power-up the inverter

Press the key

Press the key and hold it

depressed until 60 Hz is reached

Press the key

Press the key

Press the key and hold it

depressed

Inverter is ready to be operated

Motor accelerates from 0Hz to 3Hz*

(min. frequency), in the forward (CW) direction

of rotation

(1)

* 90rpm for 4 pole motor.

Motor accelerates up to 60Hz*

(2)

* 1800rpm for 4-pole motor

Motor decelerates

(3)

down to 0 rpm and

then reverses the direction of rotation

CW⇒CWW accelerating back to 60Hz

Motor decelerates down to 0 rpm

Motor accelerates up to JOG frequency

given by P122. Ex: P122 = 5.00Hz.

Reverse (CCW)

DANGER!

Even after the AC power supply has been disconnected, high voltages

may be still present. Wait at least 10 minutes after powering down to

allow full discharge of the capacitors.

The sequence below is valid for the connection 1 (refer to Section 3.2.5).

Inverter must be already installed and powered up according to Chapter 3

and Section 4.2.

This Section describes start-up procedures when operating via the keypad

(HMI). Two types of control will be considered:

V/F and Vetor Control

The V/F control is recommended in the following cases:

several motors driven by the same inverter;

rated current of the motor is lower than 1/3 of rated inverter current

for test purposes, inverter is start-up without load.

The V/F control can also be used in applications that do not require fast

dynamic responses, accurate speed regulations or high starting torque

(speed error will be a function of the motor slip); when you program

parameter P138 - rated slip - you can obtain a speed accuracy of 1%.

For the most applications, we recommend the vector control mode, that

permits a higher speed control accuracy (typical 0.5%), higher starting

torque and a faster dynamic response.

Loading...

Loading...