133

CFW-08 OPTIONS AND ACCESSORIES

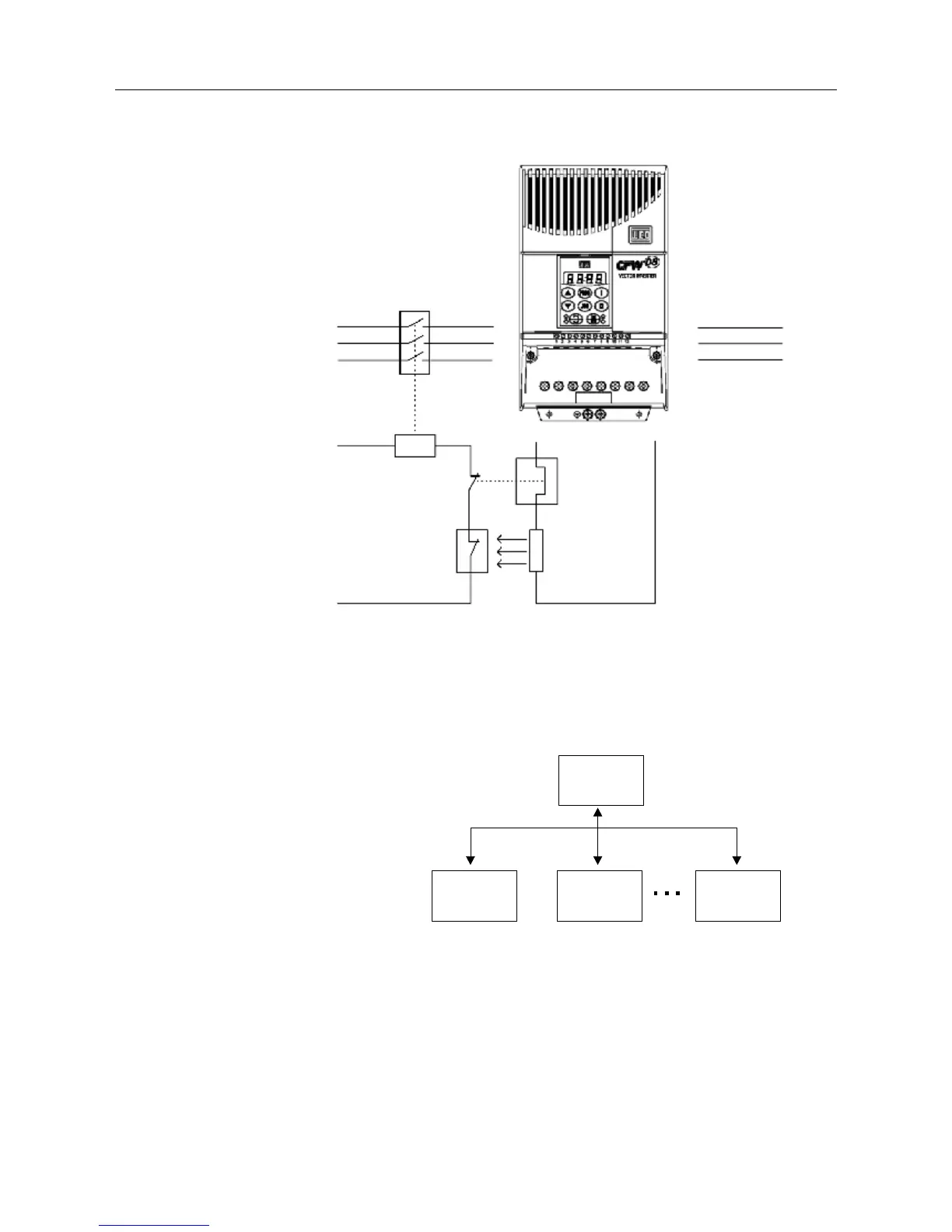

Figure 8.23 - Braking resistor connection

(only for models 7.3-10-16A/200-240V e 2.7-4.3-6.5-10-13-16/380-480V)

8.19 SERIAL

COMMUNICATION

MOTOR

POWER

SUPPLY

CONTACTOR

CONTROL POWER

SUPPLY

OVERLOAD

RELAY

THERMOSTAT

BRAKING

RESISTOR

U

V

W

R

S

T

BR +UD

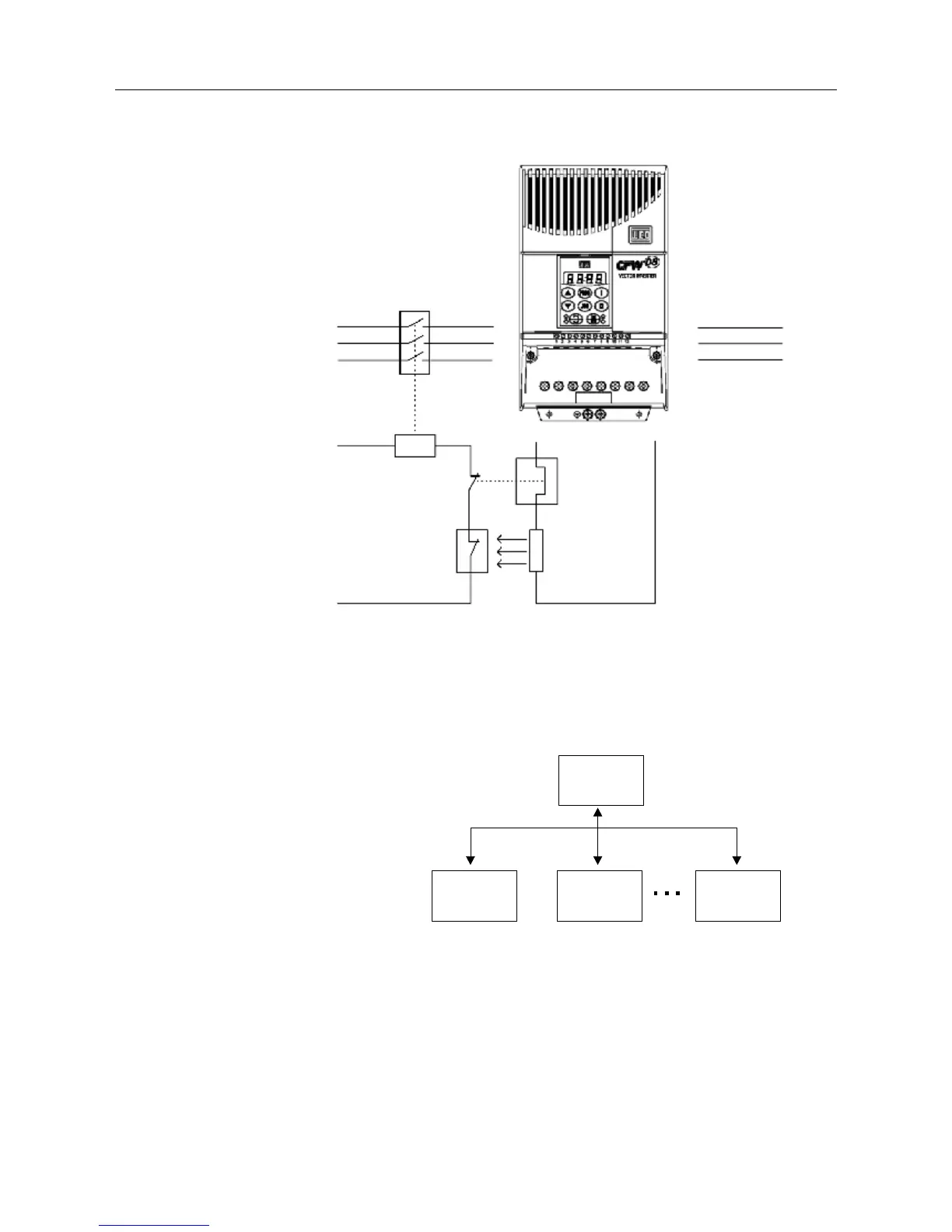

Master PC, PLC, etc.

Slave 1

(Inverter)

Slave 2

(Inverter)

Slave n

(Inverter)

n ≤ 30 for WEG Protocol

n ≤ 247 for Modbus-RTU

8.19.1 Introduction

The basic objective of the serial communication is the physical connection

of the inverters in an equipment network configured as follows:

The inverters have a control software for data transmission/reception through

serial interface, thus facilitating the reception of data that have been sent

by the master and the transmission of the data requested by the master.

This software supports WEG protocol and nine different Modbus-RTU

modes, that can be selected via parameter P312. The subjects broached

in this Section refers to WEG protocol. For more details about the Modbus-

RTU, see item 8.19.

The transfer rate is 9600 bits/s, following an exchange protocol of question/

answer typeby using ASCII characters.

The master is able to realize the following operations related to each

inverter:

Loading...

Loading...