GENERAL

DESCRIPTION

PISTON

AND

PISTON

RINGS

This engine employs the E-TVCS VERSION-II

so

that

the improved combustion surface at the

top

of

the piston enables more complete com-

bustion efficiency than the conventional

models.

The profile and the offset

of

the piston are

optimized

to

reduce piston slap. The oil

jet

at

the

small end

of

the connecting rod reduces the

heat

load of the piston.

TOP

RING

I I \

~~~G

r;

I \ -

....

;:.

OILRING

~

PISTON

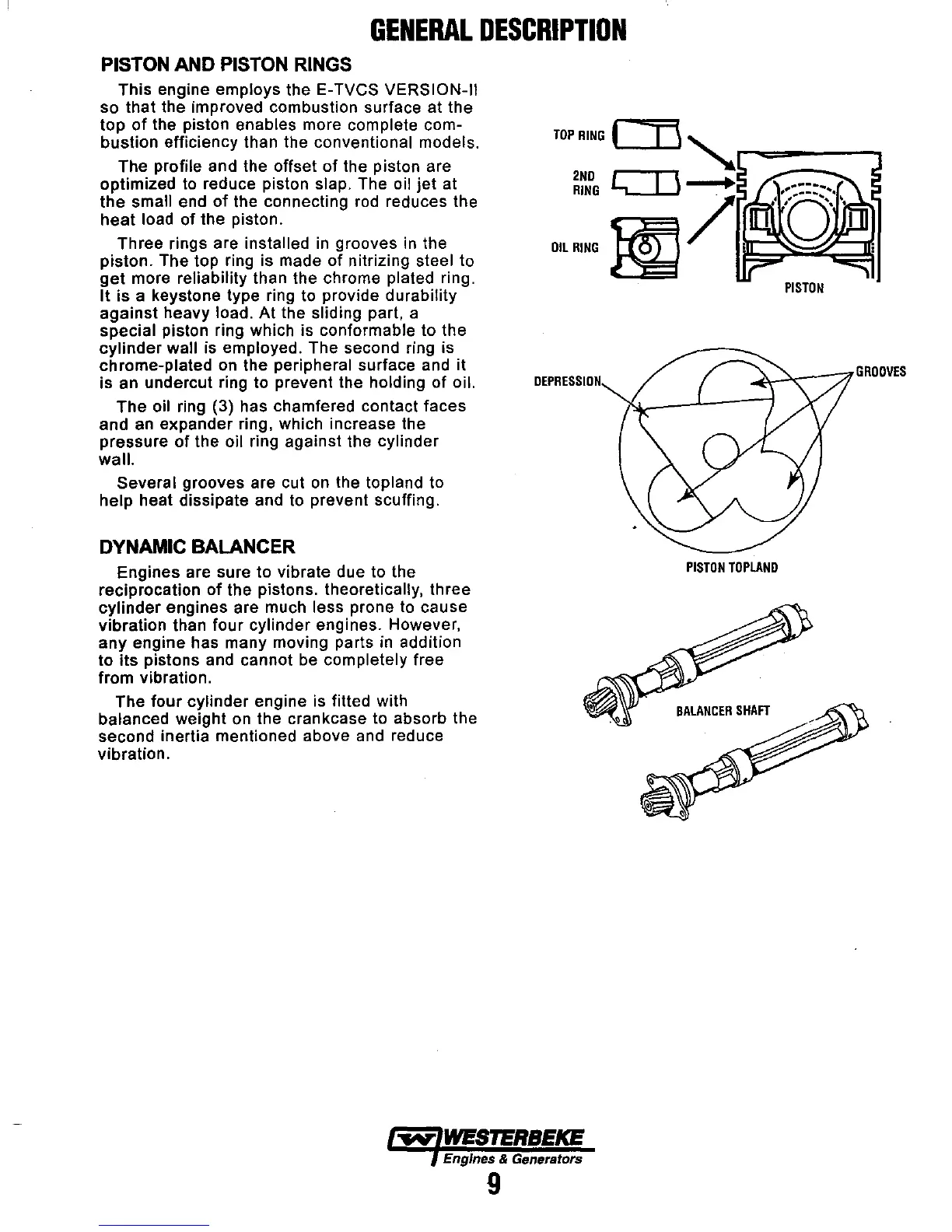

Three rings are installed

in

grooves

in

the

piston. The top ring is made

of

nitrizing steel to

get

more reliability than the chrome plated ring.

It

is

a keystone type ring to provide durability

against heavy load. At the Sliding part, a

special piston ring which is conformable to the

cylinder wall is employed. The second ring is

chrome-plated on the

peripheral surface and it

is

an undercut ring to prevent the holding

of

oil.

DEPRESSION

~~~_77GROOVES

The oil ring (3) has chamfered contact faces

and an expander ring, which increase the

pressure

of

the oil ring against the cylinder

wall.

Several

grooves are cut

on

the topland to

help heat dissipate and to prevent scuffing.

DYNAMIC

BALANCER

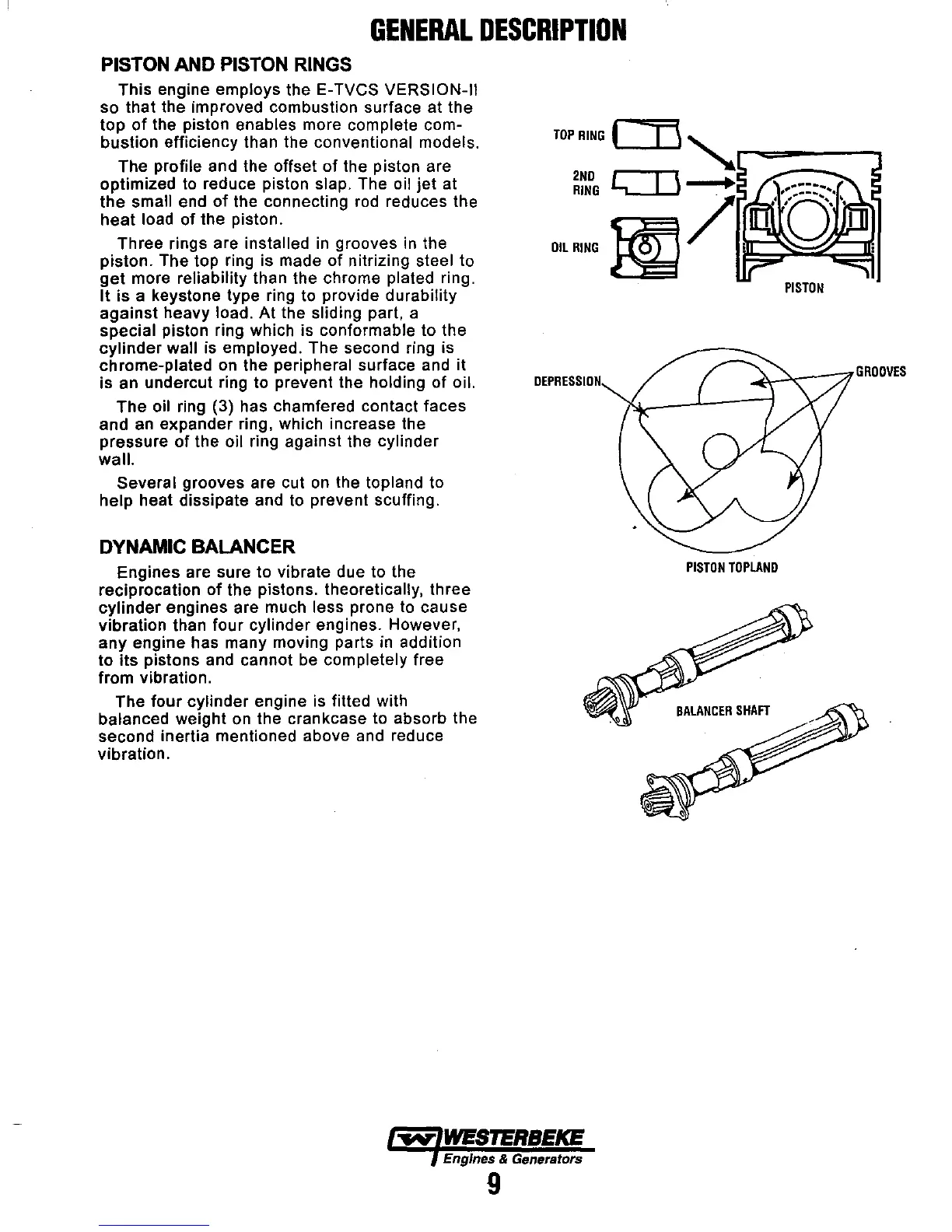

Engines are sure to vibrate due to the

reciprocation

of

the pistons. theoretically, three

cylinder engines are much less prone to cause

vibration than four

cylinder engines. However,

any engine has many moving parts

in

addition

to its pistons and cannot be

completely free

from vibration.

The

four

cylinder engine is fitted with

balanced weight

on

the crankcase to absorb the

second inertia mentioned above and reduce

vibration.

-.v

WESTERBEKE

Engines &

Generators

9

PISTON

TOPLAND

BALANCER

SHAFT

Loading...

Loading...