-

SERVICING

Cylinder Head

Too Clearance

1.

Remove the cylinder head (remove the cylinder head gasket

completely).

2.

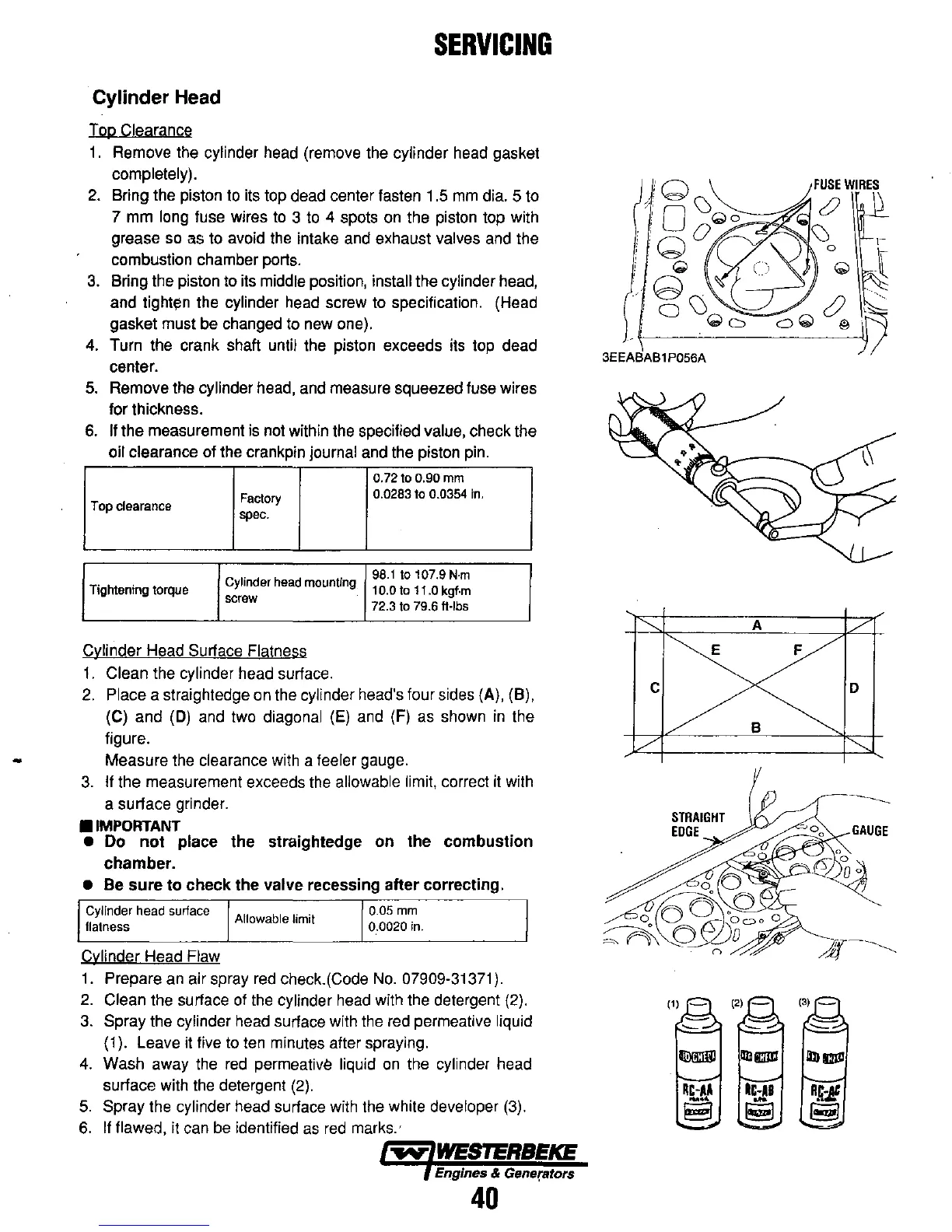

Bring the piston to its top dead center fasten 1.5 mm dia. 5 to

7

mm

long fuse wires to 3 to 4 spots on the piston top with

grease so

as

to avoid the intake and exhaust valves and the

combustion chamber ports.

3. Bring the piston to its middle position, install the cylinder head,

and tighten the

cylinder head screw to specification. (Head

gasket must be changed to new one).

4. Turn the crank shaft until the piston exceeds its top dead

center.

5.

Remove the cylinder head, and measure squeezed fuse wires

for thickness.

6.

If

the

measurement is not within the specified value, check the

oil

clearance

of

the crankpin journal and the piston pin.

0.72

to

0.90

mm

Factory

0.0283

to

0.0354 in.

Top clearance

spec.

Cylinder

head

mounting

98.1

to

107.9

N·m

Tightening

torque

10.0

to

11.0

kgf·m

screw

72.3

to

79.6 ft·lbs

Cylinder Head Surface Flatness

1.

Clean the cylinder head surface.

2.

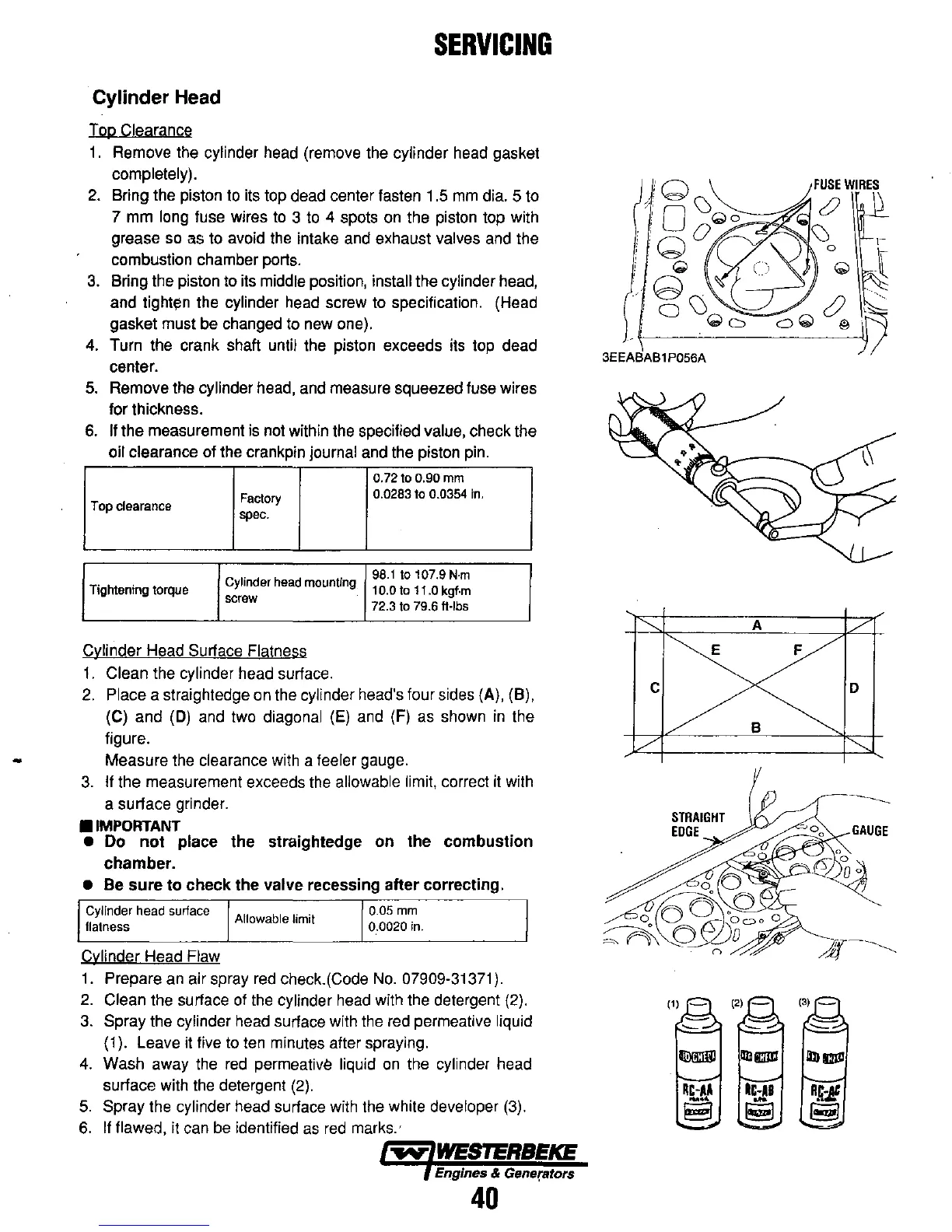

Place a straightedge on the cylinder head's four sides (A), (B),

(C)

and

(D) and two diagonal (E) and (F) as shown

in

the

figure.

Measure the clearance with a

feeler gauge.

3.

If the measurement exceeds the allowable limit, correct it with

a surface grinder.

• IMPORTANT

•

Do

not

place

the

straightedge

on

the

combustion

chamber.

•

Be

sure

to

check

the

valve

recessing

after

correcting.

Cylinder

head

surface

flatness

Cylinder Head Flaw

Allowable limit

0.05 mm

0.0020 in.

1.

Prepare an air spray red check.(Code No. 07909·31371).

2.

Clean the surface of the cylinder head with the detergent (2).

3.

Spray the cylinder head surface with the red permeative liquid

(1). Leave it five to ten minutes after spraying.

4. Wash away the red permeative

liquid on the cylinder head

surface with the detergent (2).

5.

Spray the cylinder head surface with the white developer (3).

6.

If

flawed, it can be identified

as

red marks.'

~~~WESTERBEKE

Engines & Generators

40

3EEABAB1P056A

A

E

F

c o

B

Ilil!mll

IDi

s:m:r

illIl:IJIl

Ac-AA

Ie-AS

A!i;f

8

~

~

Loading...

Loading...