FUEL

SYSTEM

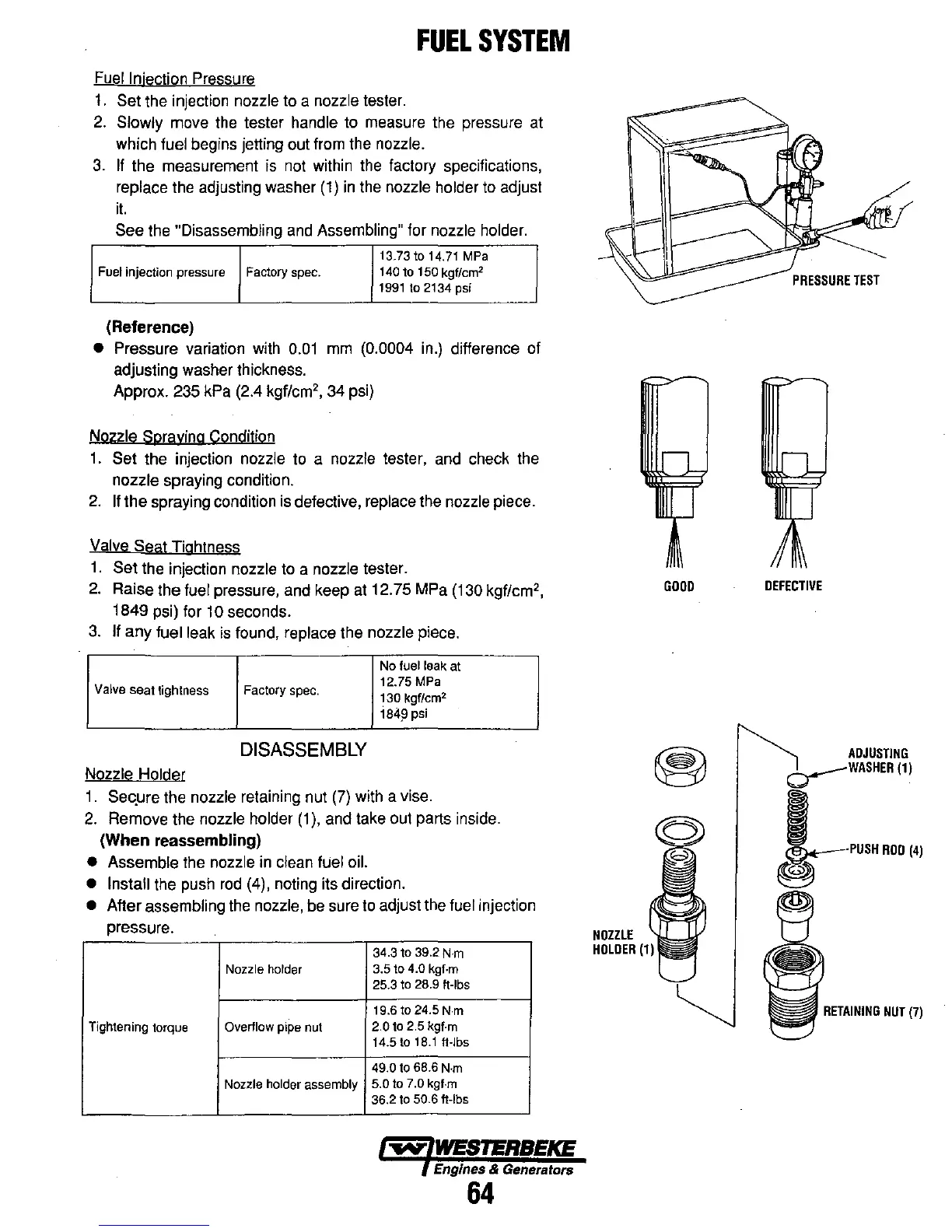

Fuel Injection Pressure

1.

Set the injection nozzle to a nozzle tester.

2.

Slowly move the tester handle to measure the pressure at

which

fuel begins jetting out from the nozzle.

3.

If

the measurement

is

not within the factory specifications,

replace the adjusting washer

(1)

in

the nozzle holder

to

adjust

it.

See the "Disassembling and Assembling" for nozzle holder.

13.73

to

14.71

MP.

Fuel

injection pressure Factory

spec.

140

to

150 kgffem'

1991102134 psi

(Reference)

• Pressure variation with

0.01

mm

(0.0004 in.) difference of

adjusting washer thickness.

Approx. 235

kPa (2.4 kgf/cm', 34 psi)

Nozzle Spraying Condition

1.

Set the injection nozzle to a nozzle tester, and check the

nozzle spraying condition.

2.

If

the spraying condition is defective, replace the nozzle piece.

Valve Seat Tightness

1.

Set the injection nozzle to a nozzle tester.

2.

Raise the fuel pressure, and keep at 12.75 MPa (130 kgf/cm',

1849 psi) for

10 seconds.

3.

If any fuel leak

is

found, replace the nozzle piece.

No fuel leak

at

Valve

seat tightness Factory

spec.

12.75

MP.

130 kgffem'

iB4~

psi

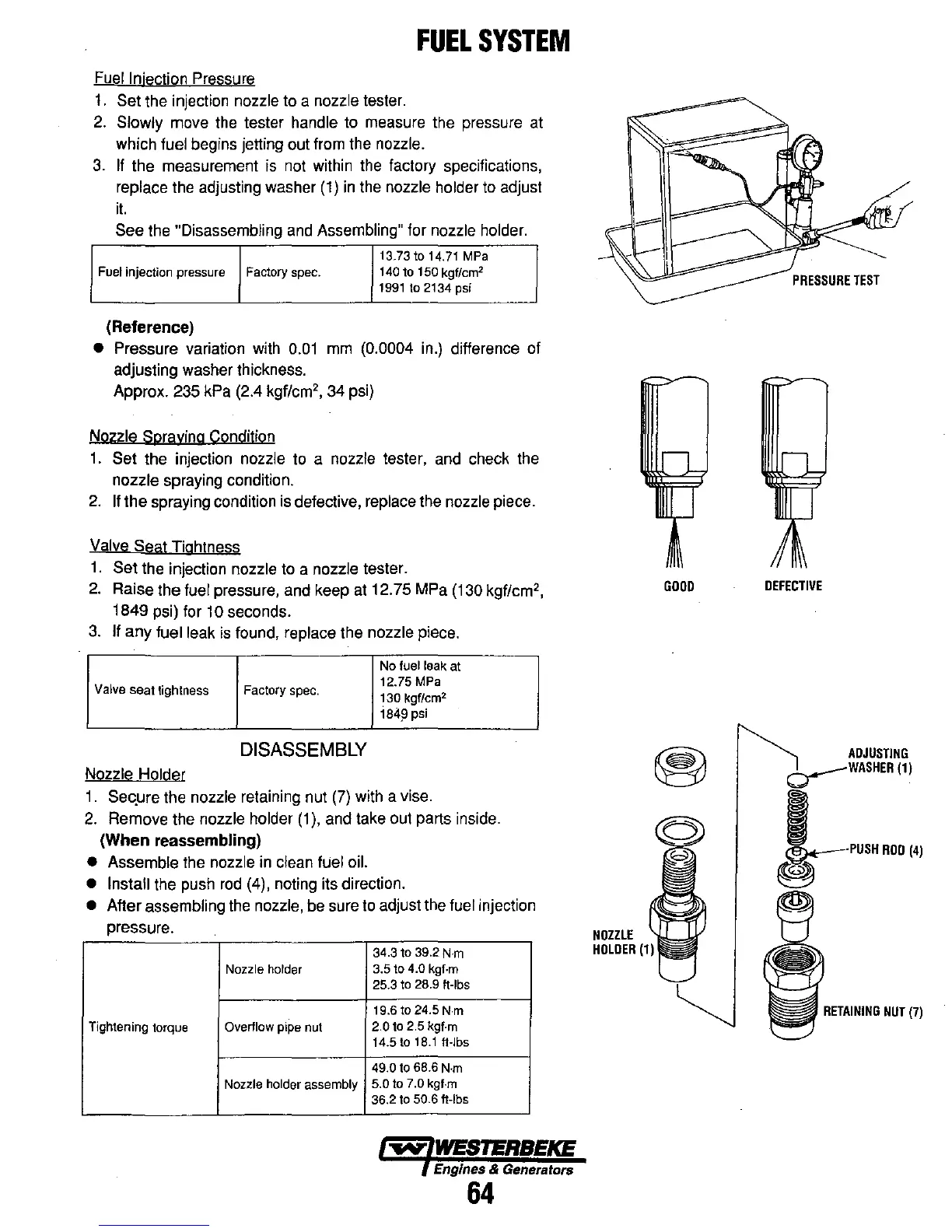

DISASSEMBLY

Nozzle Holder

1.

Sec.ure the nozzle retaining nut

(7)

with a vise.

2.

Remove the nozzle holder (1), and take out parts inside.

(When reassembling)

• Assemble the nozzle in clean fuel oil.

• Install

the push

rod

(4), noting its direction.

• After assembling the nozzle, be sure to adjust the fuel injection

pressure.

34.3

to

39.2

Nm

Nozzle holder 3.5

to

4.0 kgf·m

25.3

to

28.9 ft·lbs

19.6

to

24.5

N·m

Tightening torque Overflow pipe nut

2.0

to

2.5 kgf·m

14.5

to

18. I ft-Ibs

49.01068.6

N·m

Nozzle holder assembly

5.0

to

7.0 kgf·m

36.2

to

50.6 ft-Ibs

...,yo

WESTERBEKE

Engines & Generators

64

NOZZLE

HOLDER

(1)

GOOD

PRESSURE

TEST

DEFECTIVE

ADJUSTING

J....._-WASHER

(1)

RETAINING

NUT

(7)

Loading...

Loading...