GENERATOR

INFORMATION

USE

OF

ELECTRIC

MOTORS

The power required

to

start an electric motor

is

considerably

more than is required to keep it running after it is started.

Some

motors

require

much

more

current

to

start

them

than

others. Split-phase (AC) motors require more current to start,

under

similar

circumstances,

than

other

types.

They

are

com-

monly used on easy-starting loads, such as washing

machines, or where loads are applied after the motor is

started, such as small power tools. Because they require 5 to

7 times as much current to start

as

to run, their use should be

avoided, whenever possible,

if

the electric motor is

to

be dri-

ven

by

a

small

generator.

Capacitor

and

repulsion-induction

motors

require

from

2

to

4

times

as

much

current

to

start

as

to

run. The current required to start any motor varies with the

load

connected

to

it.

An

electric

motor

connected

to

an

air

compressor, for example, will require more current than a

motor to which no load is connected.

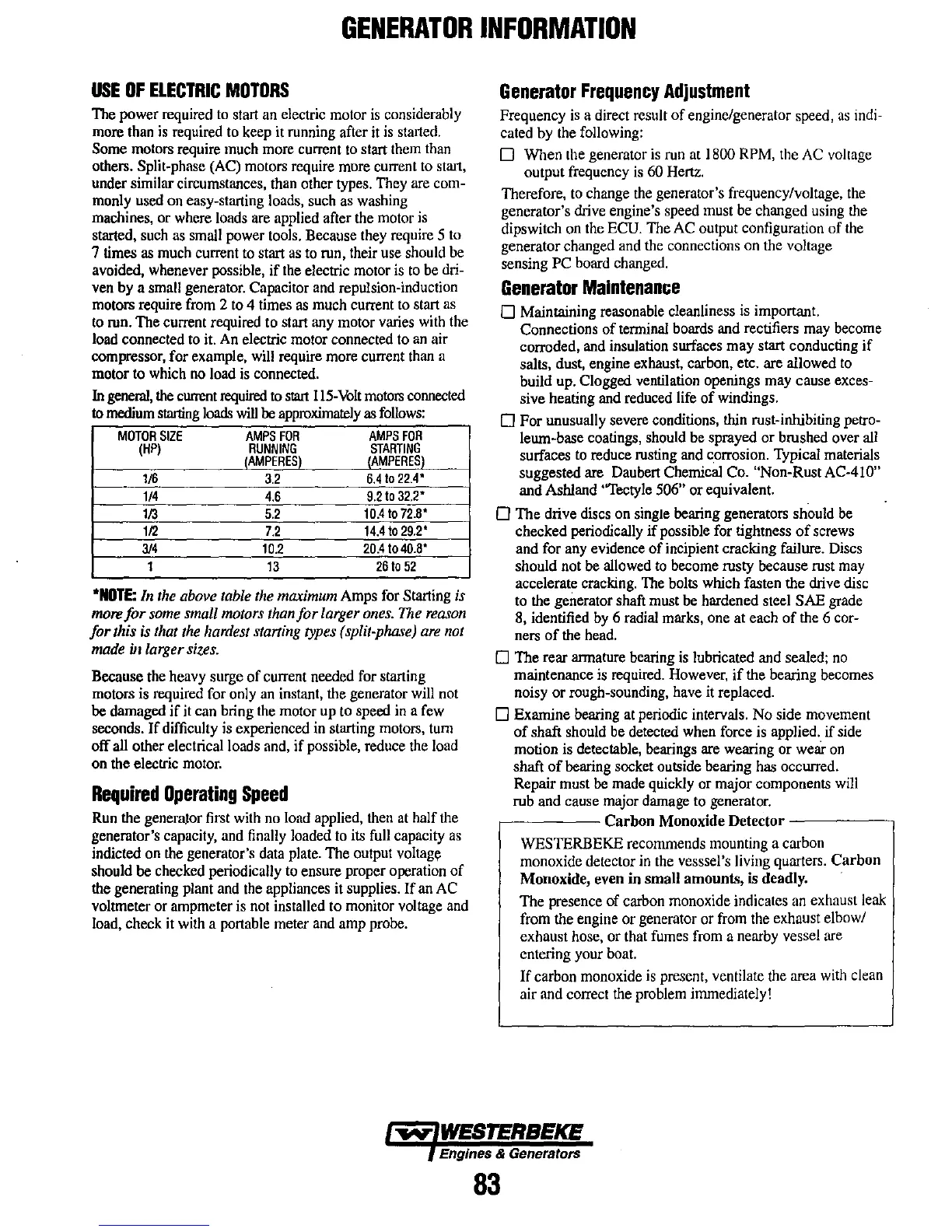

In

general, the cunent required

to

start

115-

\bIt

motors connected

to medium starting loads will be approximately as follows:

MOTOR

SIZE

AMPS

FOR

AMPS

FOR

(HPJ

RUNNING

(~TARTIN~)

(AMPERES)

AMPERES

1/6

3.2

6.4

to

22.4'

114

4.6

9.2

to

32.2'

113

5.2

10.4

to

72.8'

112

7.2

14.4

to

29.2'

314

10.2

20.4

to

40.8'

1

13

26

to

52

"NOTE:

In

Ihe

above

lable

Ihe

maximum

Amps for Starting is

more

for

some

small

molors

Ihan

for

larger

ones.

The

reason

for

Ihis

js

Ihallhe

hardesl

slaning

types

(Splil-phase)

are

nol

made

jn

larger

sizes.

Because the heavy surge

of

current needed for starting

motors

is

required

for

only

an

instant,

the

generator

will

not

be damaged

if

it can bring the motor up to speed in a few

seconds.

If

difficulty is experienced in starting motors, turn

off all other electrical loads and,

if

possible, reduce the load

on the electric motor.

Required

Operating

Speed

Run the genera)or first with no load applied, then at half the

generator's capacity, and finally loaded

to

its full capacity

as

indicted on the generator's data plate. The output voltage

should be checked periodically to ensure proper operation

of

the generating plant and the appliances it supplies.

If

an AC

voltmeter or ampmeter is not installed to monitor voltage and

load, check it with a portable meter and amp probe.

Generator

Frequency

Adjustment

Frequency

is

a direct result

of

engine/generator speed,

as

indi-

cated by the following:

o When the generator

is

run at 1800 RPM, the AC voltage

output frequency is

60 Hertz.

Therefore, to change the generator's frequency/voltage, the

generator's drive engine's speed must be changed using the

dips witch on the

ECU. The

AC

output configuration

of

the

generator

changed

and

the

connections

on

the

voltage

sensing PC board changed.

Generator

Maintenance

o Maintaining reasonable cleanliness is important.

Connections

of

terminal boards and rectifiers may become

corroded, and insulation surfaces

may

start conducting

if

salts, dust, engine

exhaus~

carbon, etc. are allowed

to

build up. Clogged ventilation openings may cause exces-

sive heating and reduced life

of

windings.

o For unusually severe conditions, thin rust-inhibiting petro-

leum-base coatings, should be sprayed

or

brushed over all

surfaces to reduce rusting and corrosion. Typical materials

suggested are Daubert Chemical Co.

"Non-Rust AC-4!o"

and Ashland "Tectyle 506"

or

equivalent.

o

The

drive discs on single bearing generators should be

checked periodically

if

possible for tightness

of

screws

and for any evidence

of

incipient cracking failure. Discs

should not be allowed

to

become rusty because rust may

accelerate cracking. The bolts which fasten the drive disc

to the generator shaft must be hardened steel

SAE

grade

8, identified by 6 radial marks, one at each

of

the 6 cor-

ners

of

the head.

o The rear armature bearing is lubricated and sealed;

no

maintenance

is

required.

However,

if

the

bearing

becomes

noisy

or

rough-sounding, have it replaced.

o Examine bearing at periodic intervals.

No

side movement

of

shaft should be detected when force is applied.

if

side

motion

is

detectable,

bearings

are

wearing

or

wear

on

shaft

of

bearing socket outside bearing has occurred.

Repair must be made quickly or major components

wiJI

rub

and

cause

major

damage

to

generator.

,-----

Carbon

Monoxide

Detector

-----,

WESTERBEKE recommends mounting a carbon

monoxide detector in the vesssel's Jiving quarters.

Carbon

Monoxide, even in

small

amounts,

is deadly.

The presence of carbon monoxide indicates an exhaust leak

from the engine

or

generator or from the exhaust elbow/

exhaust hose,

or

that

fumes

from

a

nearby

vessel

are

entering your boat.

If

carbon monoxide is present, ventilate the area with clean

air and correct the problem immediately!

Eng/nes & Generators

83

Loading...

Loading...