ENGINE

ADJUSTMENTS

Checking Valve Clearance

•

IMPORTANT

• Valve clearance

must

be checked and adjusted when

engine

is cold.

1.

Remove the head cover.

2.

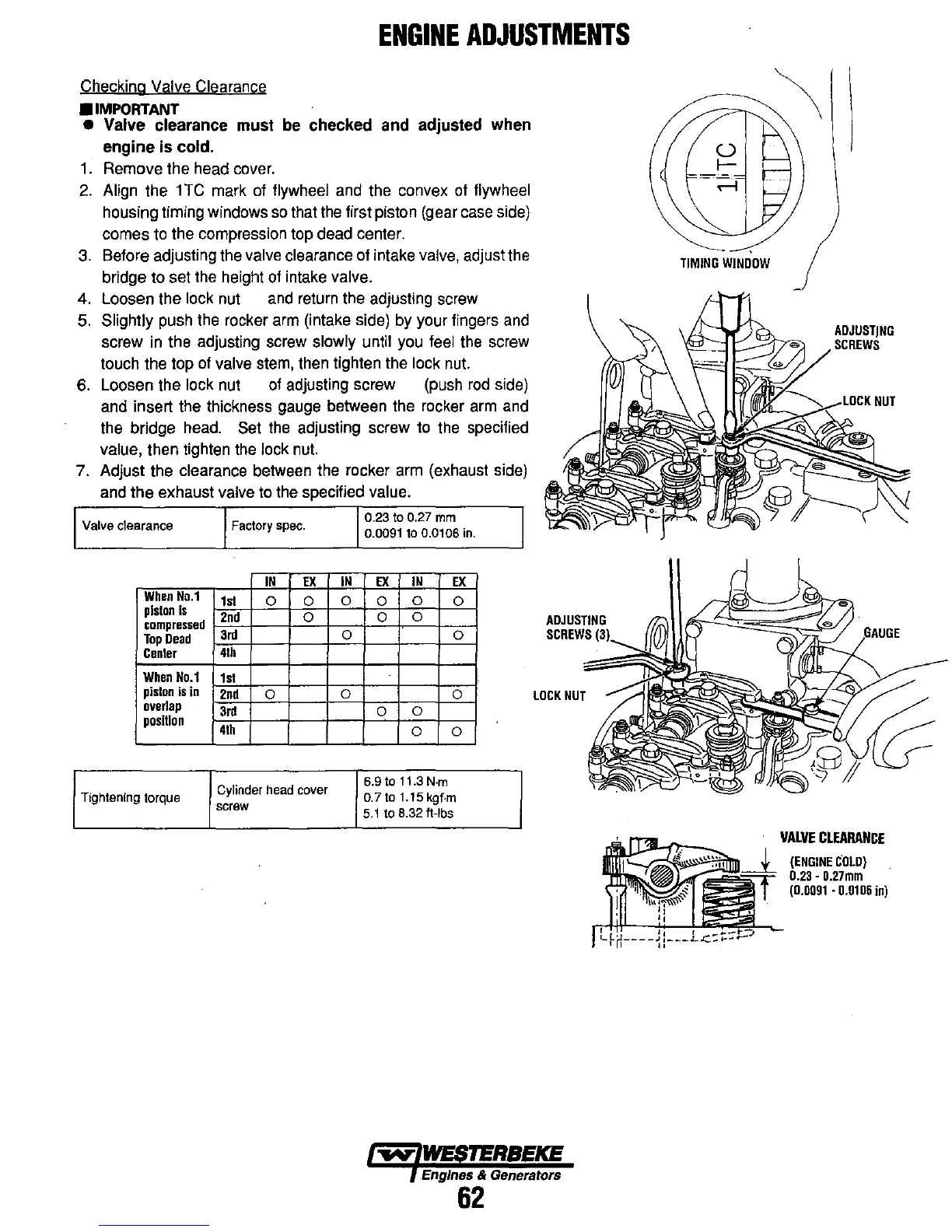

Align the

HC

mark of flywheel and the convex

of

flywheel

housing timing windows

so

that

the

first piston (gear case side)

comes to the compression top dead center.

3.

Before adjusting the valve clearance of intake valve, adjust the

bridge to set the height of intake valve.

4. Loosen the lock nut

and

return the adjusting screw

5.

Slightly push the rocker arm (intake side)

by

your fingers

and

screw

in

the adjusting screw slowly until

you

feel the screw

touch the top

of

valve stem, then tighten the lock nut.

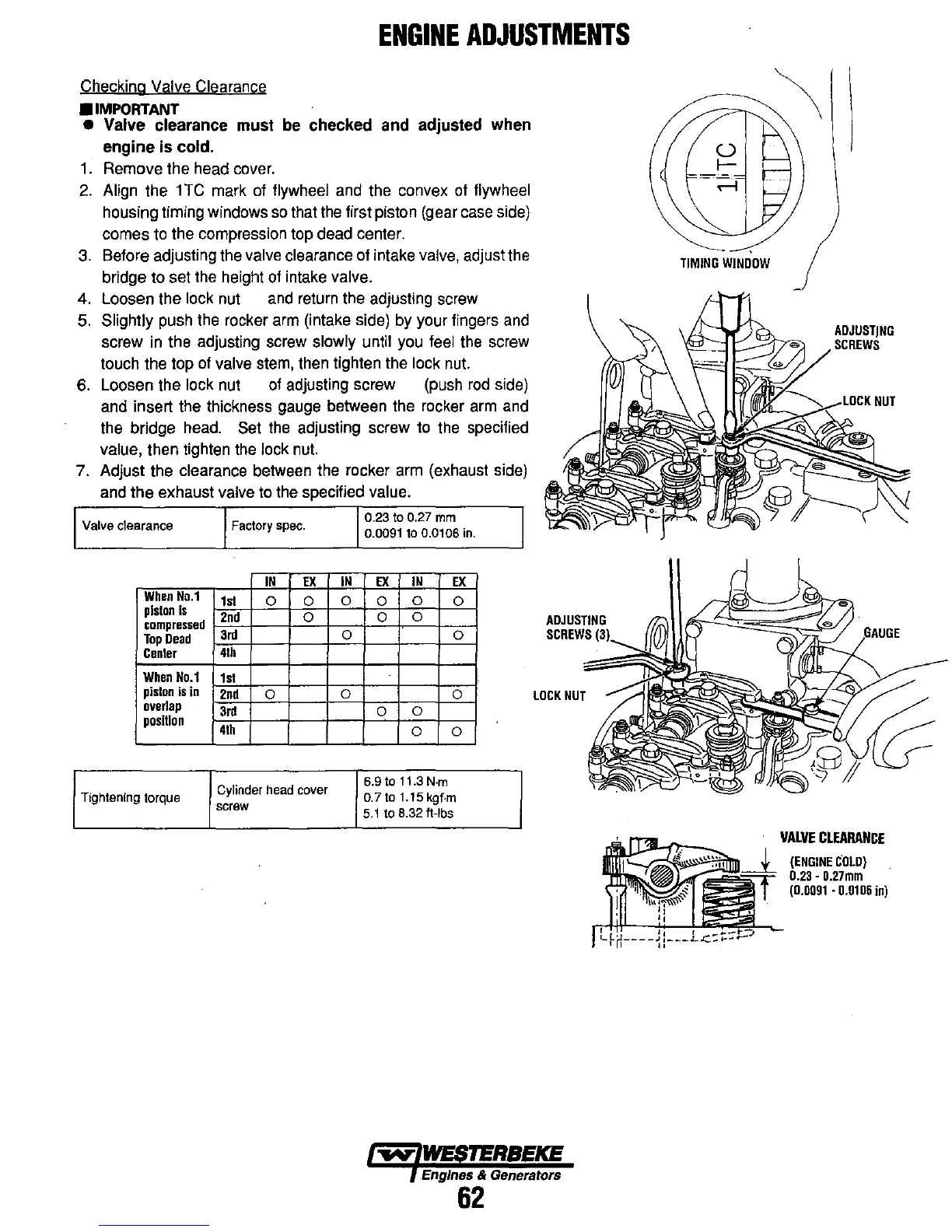

6. Loosen the lock nut of adjusting screw (push

rod

side)

and insert the thickness gauge between the rocker

arm

and

the bridge head. Set

the

adjusting screw to

the

specified

value, then tighten

the

lock nut.

7. Adjust the clearance between the rocker arm (exhaust side)

and the exhaust valve to the specified value.

Valve

clearance

Factory

spec.

IN

EX

When

No.1

1s1

0 0

piston

Is

2nd

0

cDmpressed

3rd

Top

Dead

Cenler

41h

When

No.1

1st

piston

is

in

2nd

0

overlap

3rd

posilion

41h

Cylinder

head

cover

Tightening

torque

screw

IN

0

0

0

0.23

to

0.27

mm

0.009t

to

O.OtOS

in.

EX

IN

EX

0

0

0

0

0

0

.

0

0

0

0 0

S.9

to

11.3

N'm

0.7

to

1.15

kgl·m

5.1

to

8.32

ft-Ibs

62

ADJUSTING

SCREWS

LOCK

NUT

TIMING

WINDOW

ADJUSTING

SCREWS

(ENGINE

COLD)

0.23

-

0.27mm

(0.0091

.

0.0106

in)

Loading...

Loading...