ENGINE

ADJUSTMENTS

Injection Timing

1.

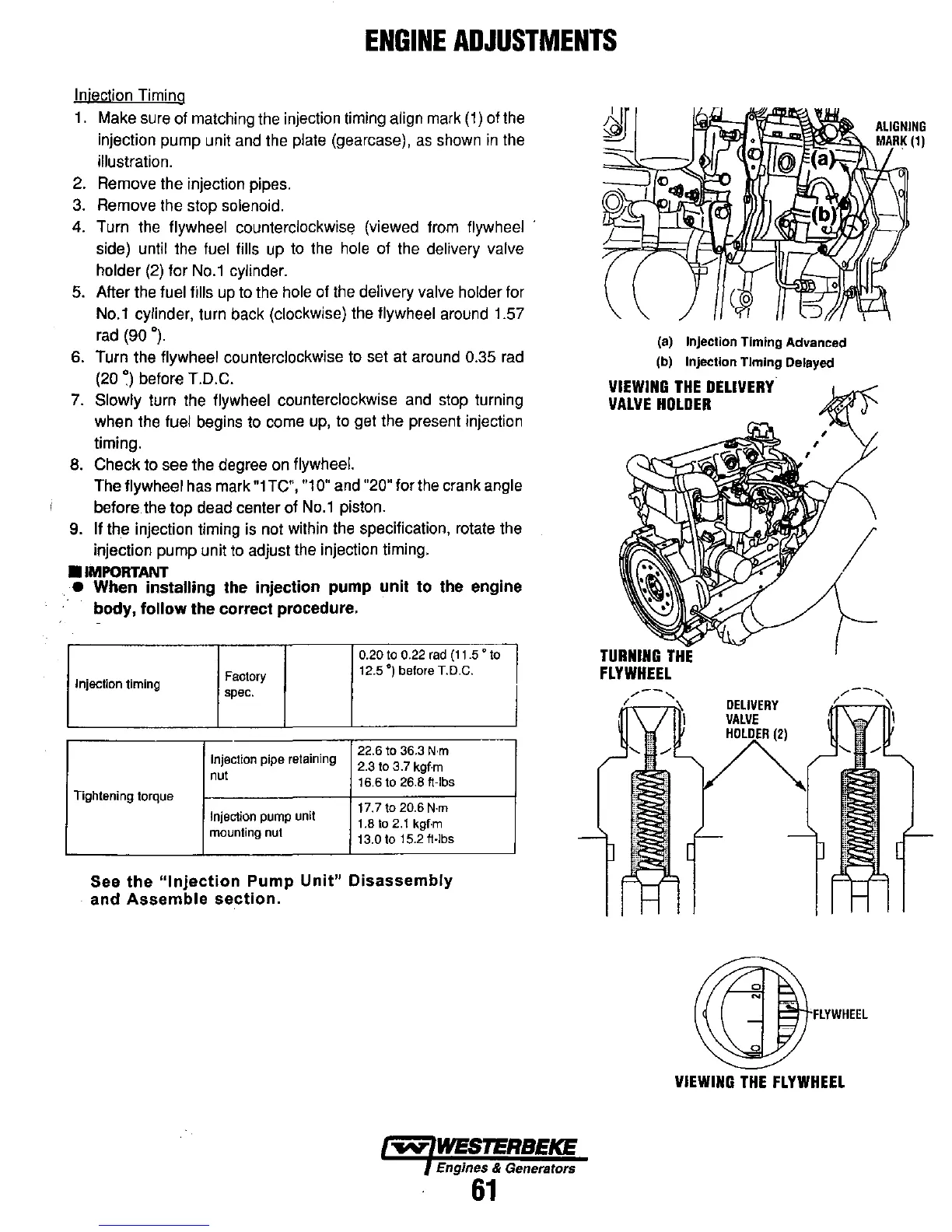

Make sure of matching the injection timing align

mark

(1)

of the

injection pump unit

and

the plate (gearcase),

as

shown

in

the

illustration.

2. Remove the injection pipes.

3.

Remove the stop solenoid.

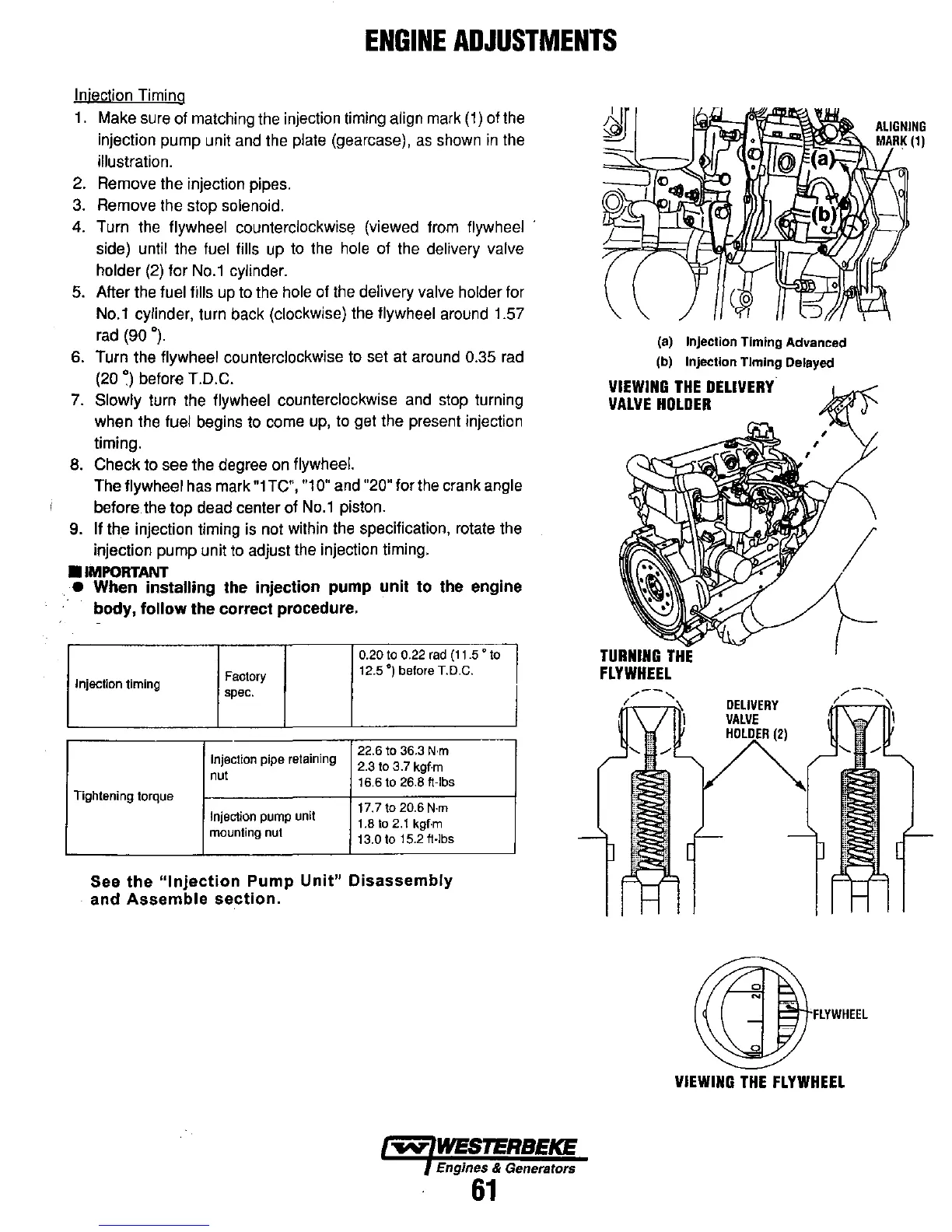

4. Turn the

flywheel counterclockwise (viewed from flywheel

side)

until the fuel fills up to the hole of the delivery valve

holder

(2)

for

No.1

cylinder.

5.

After the fuel fills

up

to the hole of

the

delivery valve holder for

No.1

cylinder, turn back (clockwise) the flywheel around 1.57

rad

(90

0).

6.

Turn the flywheel counterclockwise to set at around 0.35

rad

(20

~)

before T.D.C.

7.

Slowly turn the flywheel counterclockwise

and

stop turning

when the

fuel begins to come

up,

to get the present injection

timing.

8. Check to see the degree

on

flywheel.

The flywheel has mark

"1

TC", "10" and "20" for the crank angle

before the top dead center of

No.1

piston.

9.

If the injection timing

is

not within the specification, rotate the

injection pump unit

to

adjust the injection timing .

•

IMPORTANT

•

When

installing

the

injection

pump

unit

to

the engine

body,

follow

the

correct

procedure.

0.20 to 0.22

rad

(t t

.5

" to

Factory

12.5")

before T.D.C.

Injection

timing

spec.

Injection pipe retaining

22.6 to 36.3

N·m

2.3 to 3.7 kgf·m

nut

16.6 to 26.8

ft-Ibs

Tightening torque

Injection

pump

unit

17.7 to 20.6

N·m

1.8 to

2.1

kgf·m

mounting

nut

13.0 to t 5.2 ft-Ibs

See

the

"Injection

Pump

Unit"

Disassembly

and

Assemble

section.

~

WESTERBEKE

Engines & Generators

61

(a)

Injection

Timing

Advanced

(b)

Injection

Timing

Delayed

VIEWING

THE

DELIVERY

VALVE

HOLDER

DELIVERY

VALVE

FLYWHEEL

VIEWING

THE

FLYWHEEL

Loading...

Loading...