DISASSEMBLY

I

ASSEMBLY

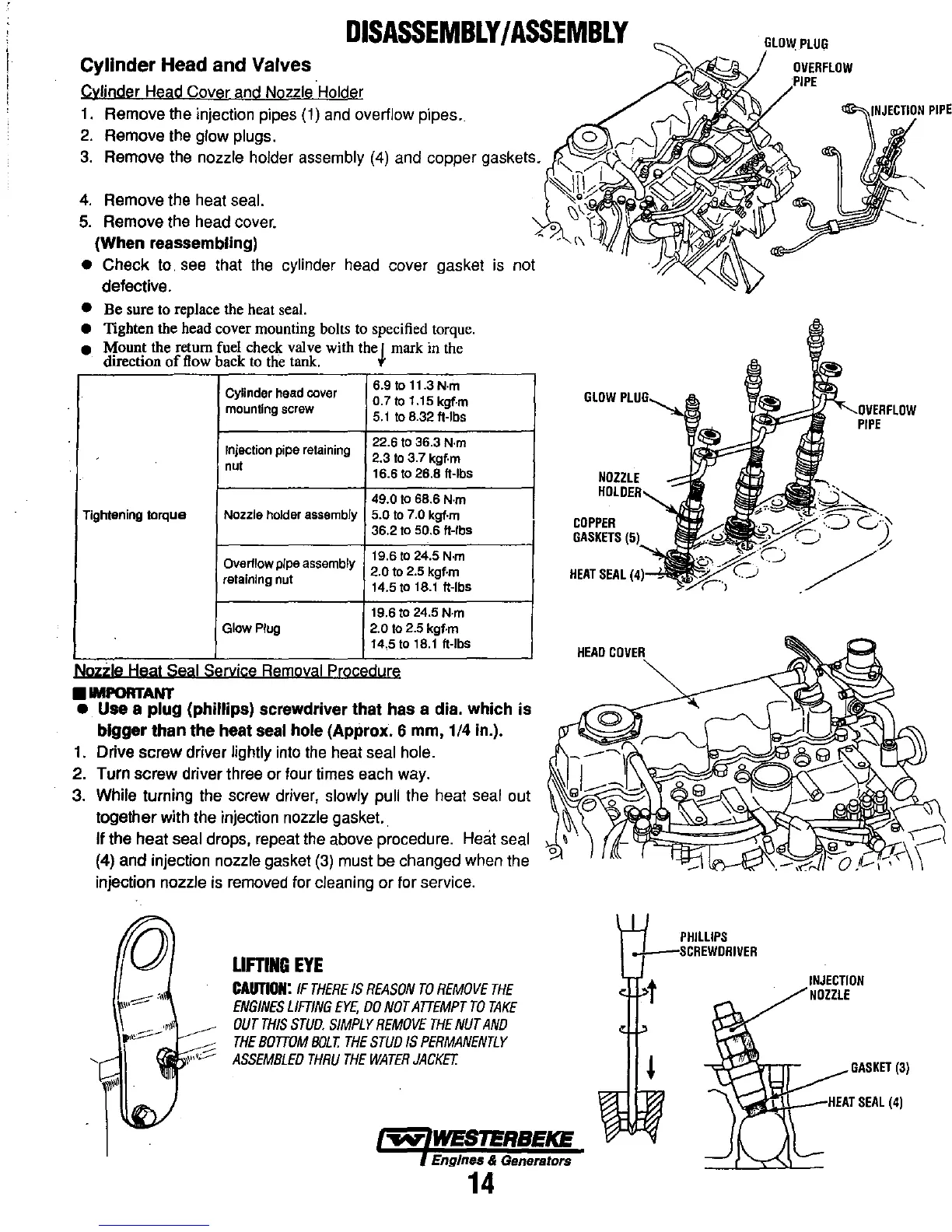

Cylinder Head and Valves

Cylinder Head Cover and Nozzle Holder

1.

Remove the injection pipes

(1)

and

overflow pipes.

2.

Remove the glow plugs.

3.

Remove the nozzle holder assembly

(4)

and copper gaskets.

4.

Remove the heat seal.

5.

Remove the head cover.

(When reassembling)

• Check to.

see

that the cylinder head cover gasket is not

defective.

•

Be

sure to replace the heat seal.

• TIghten the head cover mounting bolts to specified torque.

• Mount the return fuel check valve with the I mark in the

direction

of

flow back to the taok. t

Cylinder head cover

6.9 to 11.3

N·m

0.7

to

1.15 kgf·m

mounting

screw

5.1

to 8.32 It-Ibs

Injection

pipe

retaining

22.6 to 36.3 N·m

2.3 to 3.7 kgf·m

nut

16.6 to 26.8

It-Ibs

49.0

to 68.6 N·m

Tightening

torque

NOlzle holder assembly 5.0 to 7.0 kgf·m

36.2

to

50.6 It-Ibs

Overflow pipe assembly

19.6 to 24.5

N·m

2.0

to 2.5 kgf·m

retaining nut

14.5

to

18.1

It-Ibs

19.6 to 24.5 N·m

Glow Plug 2.0 to 2.5 kgf-m

14.5 to

18.1

It-Ibs

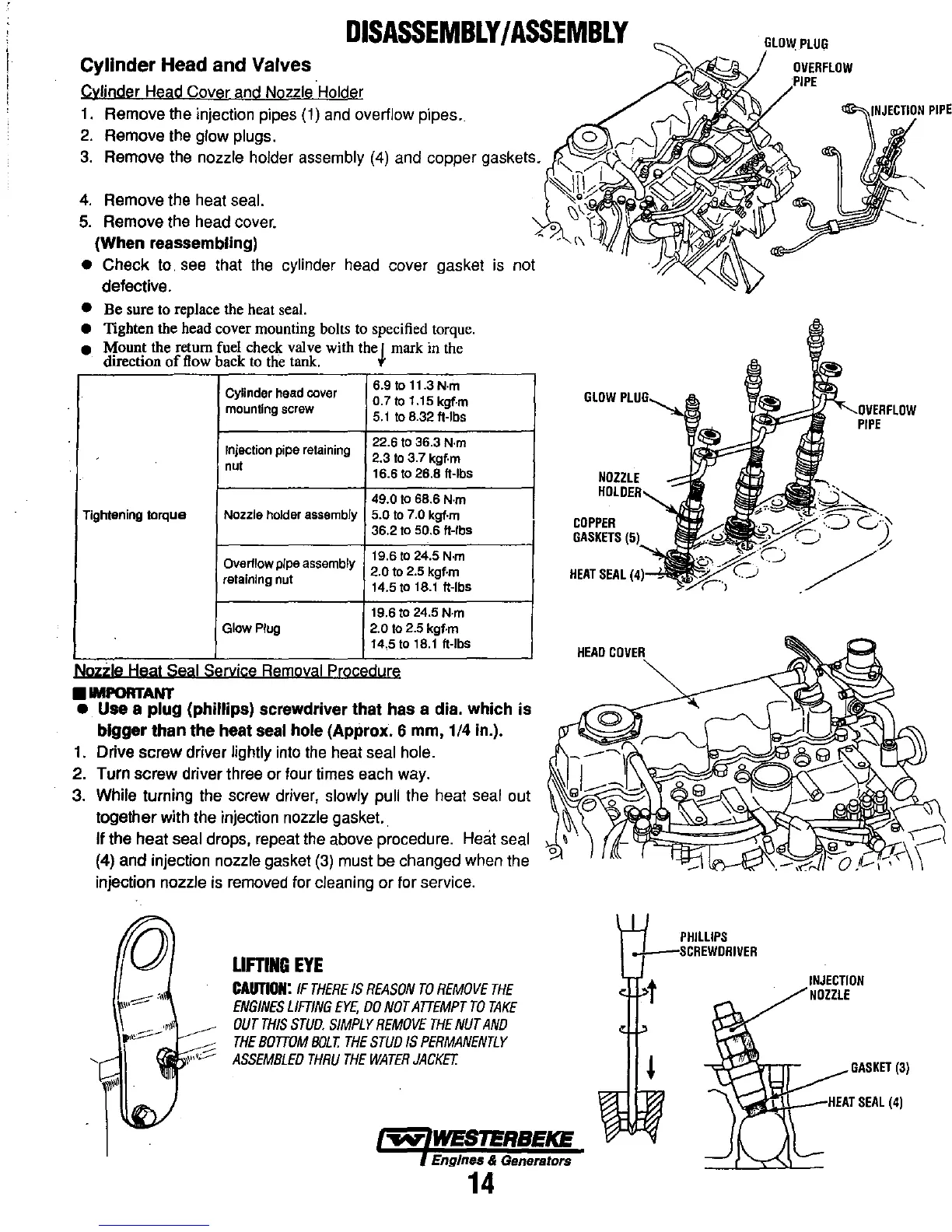

Nozzle Heat Seal Service Removal Procedure

•

IMPORTANT

•

Use

a

plug

(phillips) screwdriver

that

has

a dia.

which

is

bigger

than

the

heat seal hole (Approx. 6 mm, 1/4 in.).

1.

Drive screw driver lightly into

the

heat seal hole.

2. Turn screw driver three or four times each way.

3. While turning the screw driver, slowly pull the heat seal out

together with the injection nozzle gasket. .

If the heat seal drops, repeat the above procedure. Hmit seal

(4) and injection nozzle gasket

(3)

must be changed when the

injection nozzle is removed for cleaning or for service.

LIFTING

EYE

CAUTION:

IF

THERE

IS

REASON

TO

REMOVE

THE

ENGINES

LIFTING

EYE,

00

NOT

ATTEMPT

TO

TAKE

OUT

THIS

STUO.

SIMPLY

REMOVE

THE

NUT

AND

THE

BOTTOM

BOLT.

THE

STUD

IS

PERMANENTLY

ASSEMBLED

THRU

THE

WATER

JACKET.

o

GLOW

NOZZLE

COPPER

GASKETS

HEAT

SEAL

HEAD

COVER

Engines & Generators

14

PHilLIPS

_",IN,JEClrION

PIPE

PIPE

INJECTION

NOZZLE

GASKET

(3)

=:r.:3::s..\..L=-

HEAT

SEAL

(4)

Loading...

Loading...