STARTER

MOTOR

SERVICE

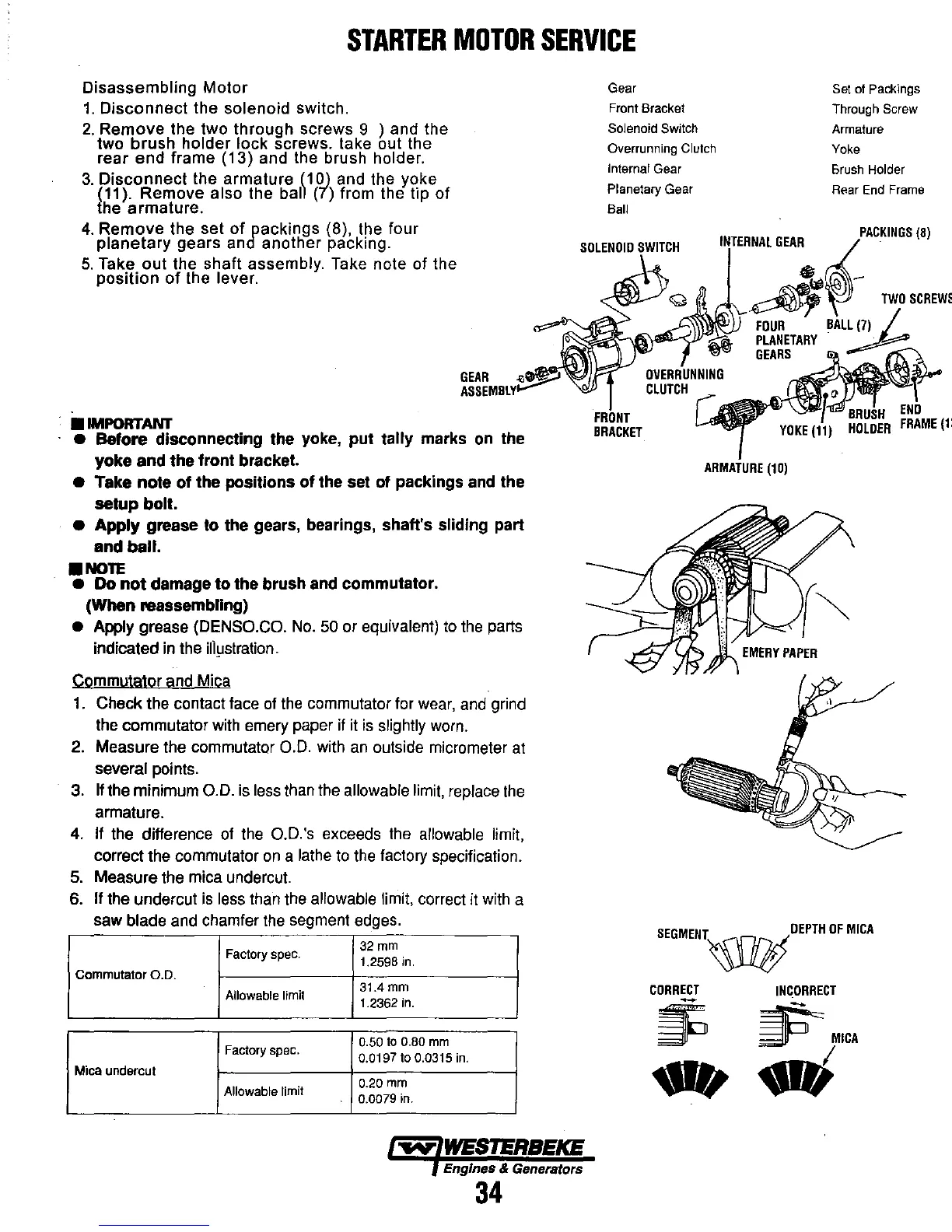

Disassembling

Motor

1.

Disconnect the solenoid switch.

2.

Remove the two through screws 9 ) and the

two

brush

holder lock screws. take out the

rear end frame (13) and the brush holder.

3.

Disconnect

the armature

(10)

and the yoke

(11). Remove also the

ball (7) from the tip

of

{he armature.

Gear

Front Bracket

Solenoid

Switch

Overrunning Clutch

Internal Gear

Planetary Gear

Sail

Set of Packings

Through Screw

Armature

Yoke

Brush

Holder

Rear End Frame

4.

Remove the set

of

packings (8), the four

planetary

gears and another packing.

SOLENOID

SWITCH

'~~~.':,~:~

5.

Take out the shaft assembly. Take note of the

position

of

the lever.

•

IMPORTANT

GEAR

..

_.-?

ASSEMBLY~

•

Before

disconnecting the yoke,

put

tally marks on the

yoke

and

the

front bracket.

• Take

note

of

the

positions

of

the set

of

packings and the

setup

bolt.

•

Apply

grease

to

the gears, bearings, shaft's sliding part

and

ball

.

•

NOTE

• Do

not

damage

to

the brush and commutator.

(When

reassembling)

•

Apply grease (DENSO.CO.

No.

50

or equivalent)

to

the

parts

indicated

in

the

illiJstration.

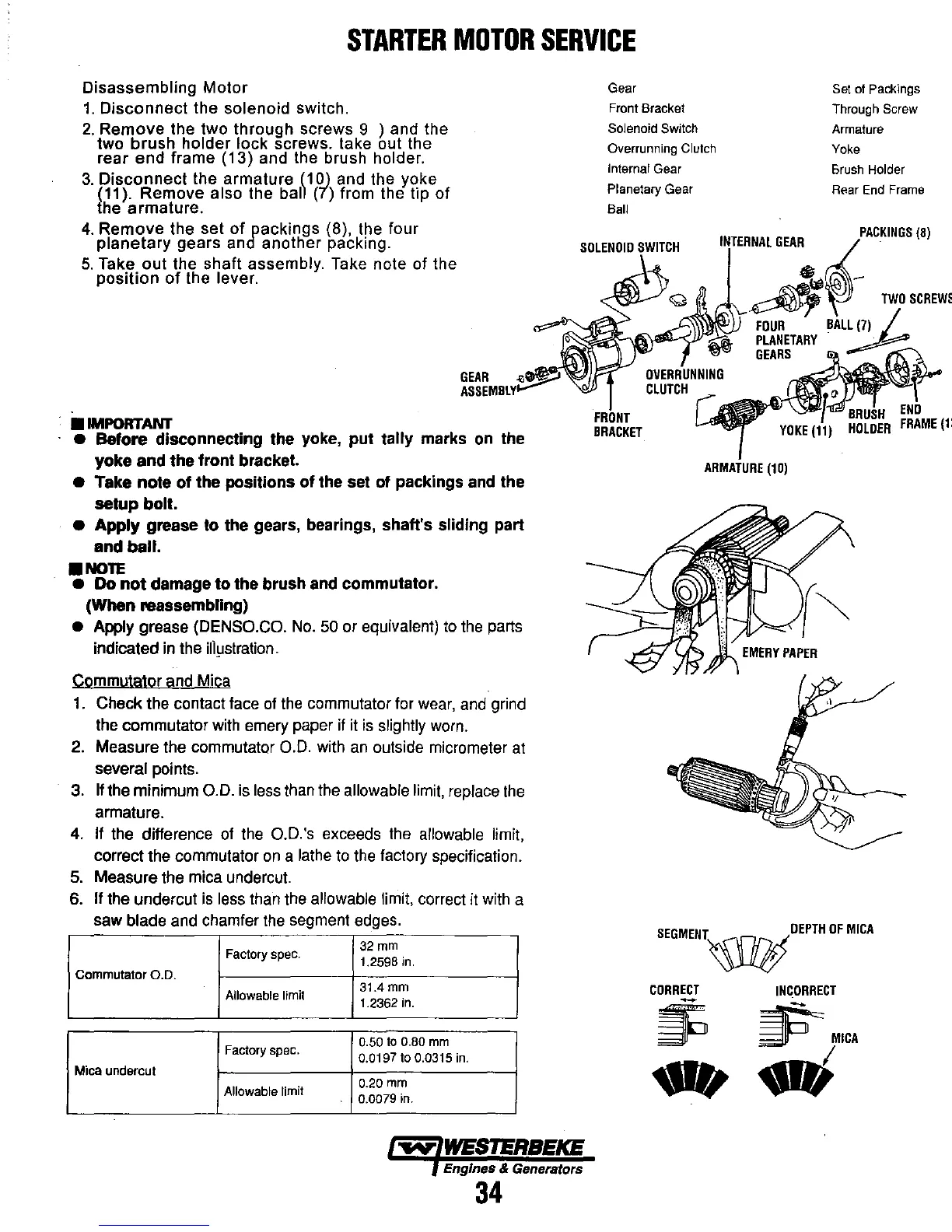

Commutator and Mica

1.

Check the contact face

of

the

commutator for

wear,

and

grind

the

commutator

with

emery paper

if

it

is

slightly

worn.

2. Measure the commutator

0.0.

with

an

outside micrometer

at

several points.

3.

If

the minimum

0.0.

is

less

than

the

allowable

limit,

replace

the

armature.

4.

If

the

difference

of

the

O.D.'s exceeds

the

allowable limit,

correct the commutator

on

a

lathe

to

the

factory specification.

5.

Measure the mica undercut.

6.

If the undercut

is

less

than

the

allowable limit, correct

it

with

a

saw blade and chamfer

the

segment edges.

Factory spec.

32mm

1.2598

in.

Commutator

0.0.

Allowable limit

31.4

mm

1.2362

in.

Factory spec.

0.50

to

0.80

mm

0.0197

to

0.0315

in.

Mica

undercut

Allowable limit

0.20

mm

0.0079 in.

-..yo"

WESTERBEKE

Engines & Generators

34

fi~\i~

FOUR

BAL~(7)

rl'-\ll.'I'I''''-""''

PLANETARY

FRONT

BRACKET

GEARS

ARMATURE

(10)

SEGMENT~OEPTH

OF

MICA

CORRECT

~

-

INCORRECT

~MICA

.;

Loading...

Loading...