STARTER

MOTOR

SERVICE

Brush Wear

1.

If

the contact face of the brush is dirty or dusty,

clean

it with

emery paper.

2.

Measure the brush length (A) with vernier calipers.

3.

If the length is less than

the

allowable limit, replace

the

yoke

assembly and brush holder.

Factory

spec.

18.0mm

0.7086 in.

Brush

length

CA)

Allowable

limit

t t.O

mm

0.433t in.

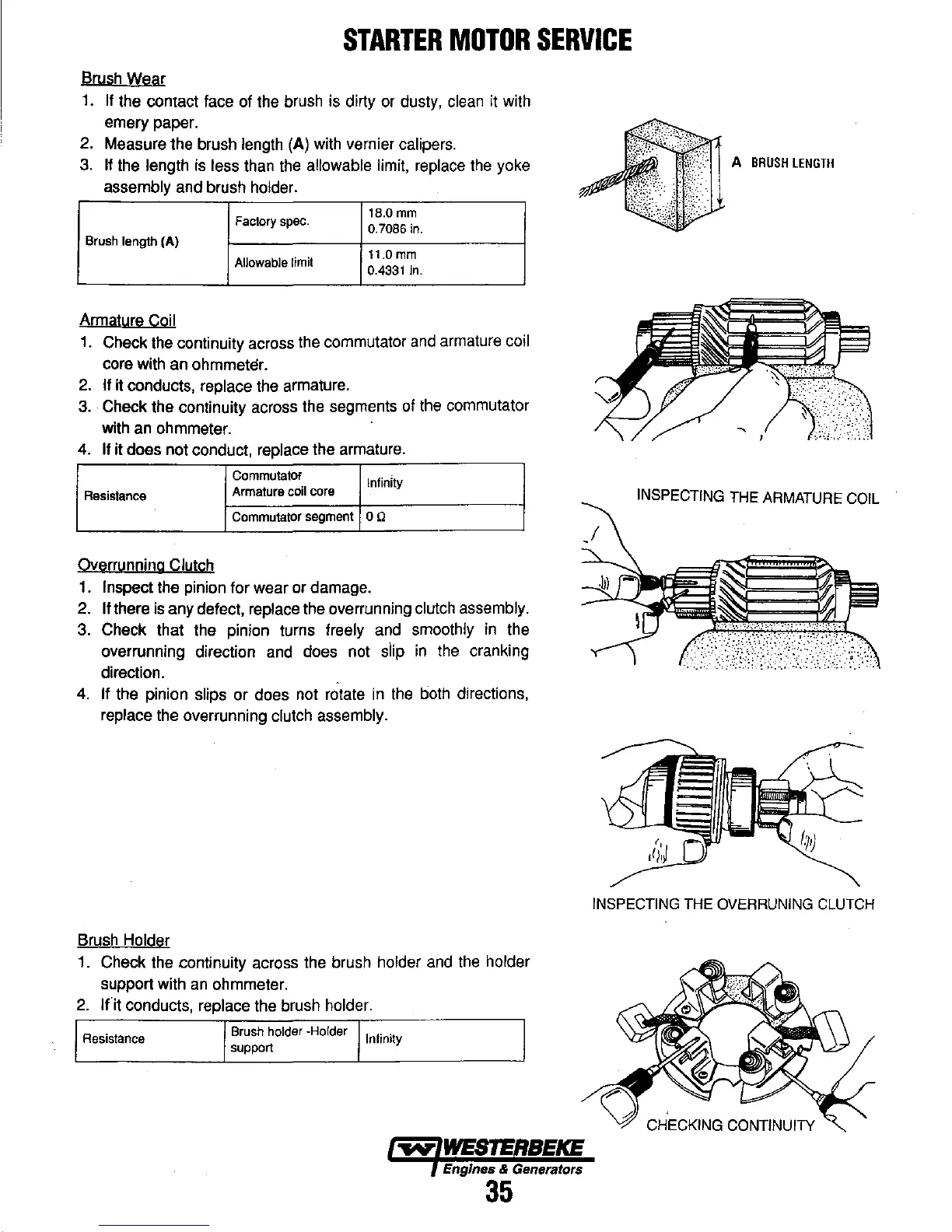

Armature Coil

1.

Check the continuity across the commutator

and

armature coil

core with an ohmmeter.

2.

If it conducts, replace the armature.

3.

Check the continuity across the segments of the commutator

with an ohmmeter.

4.

If it does not conduct, replace the armature.

Commutator

Infinity

Resistance

Armature

coil

core

Commutator

segment

OQ

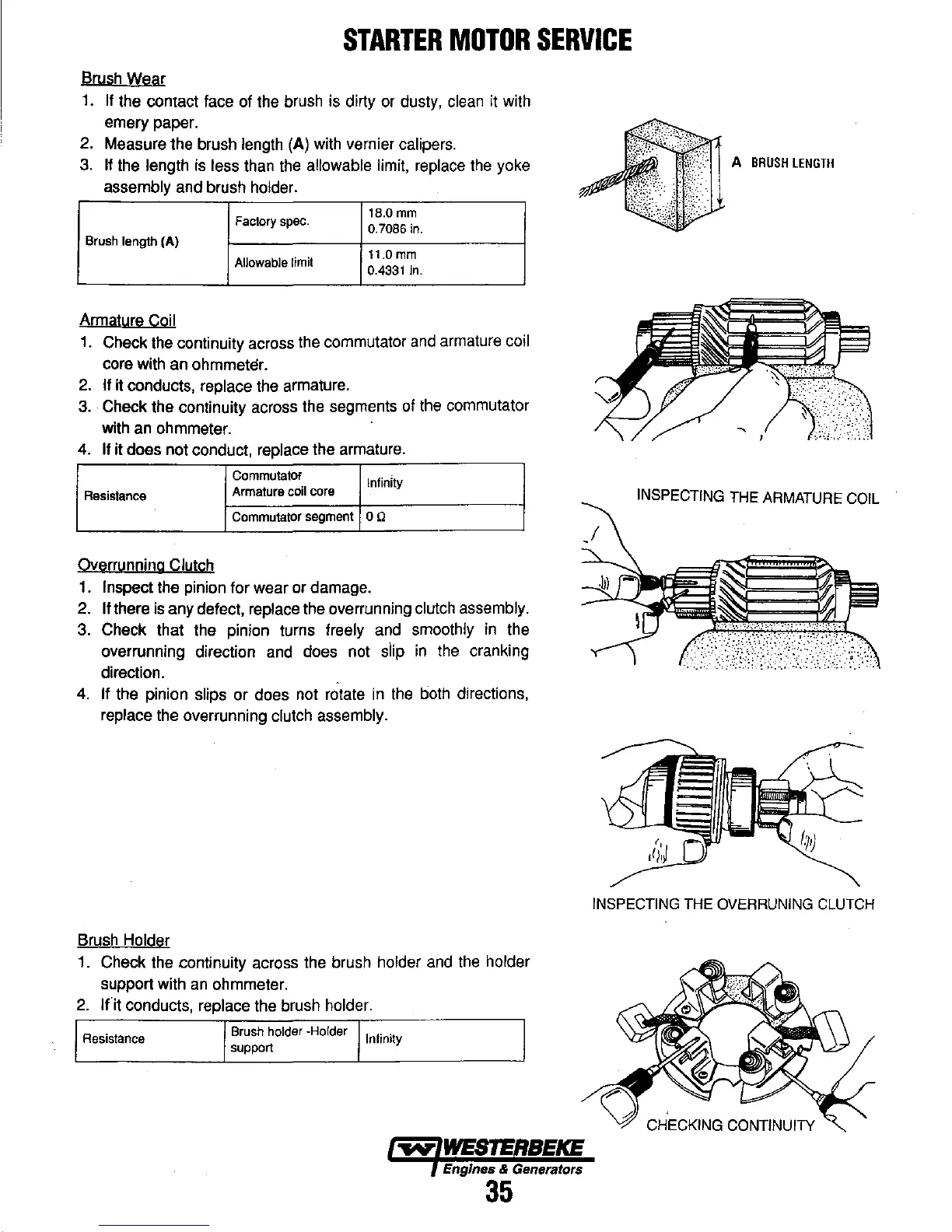

Overrunning Clutch

1.

Inspect the pinion for wear or damage.

2.

If there is any defect, replace the overrunning clutch assembly.

3.

Check that the pinion turns freely and smoothly

in

the

overrunning direction

and

does not siip

in

the

cranking

direction.

4.

If the pinion slips or does not rotate

in

the

both directions,

replace the overrunning clutch assembly.

Brush Holder

1.

Check the continuity across the brush holder

and

the

holder

support with an ohmmeter.

2.

lfit

conducts, replace the brush holder.

Resistance

Brush

holder

-Holder

support

Infinity

Engines & Generators

35

A

BRUSH

lENGTil

INSPECTING THE ARMATURE COIL

INSPECTING

THE OVERRUNING CLUTCH

Loading...

Loading...