GENERAL

DESCRIPTION

FORK

LEVER

2

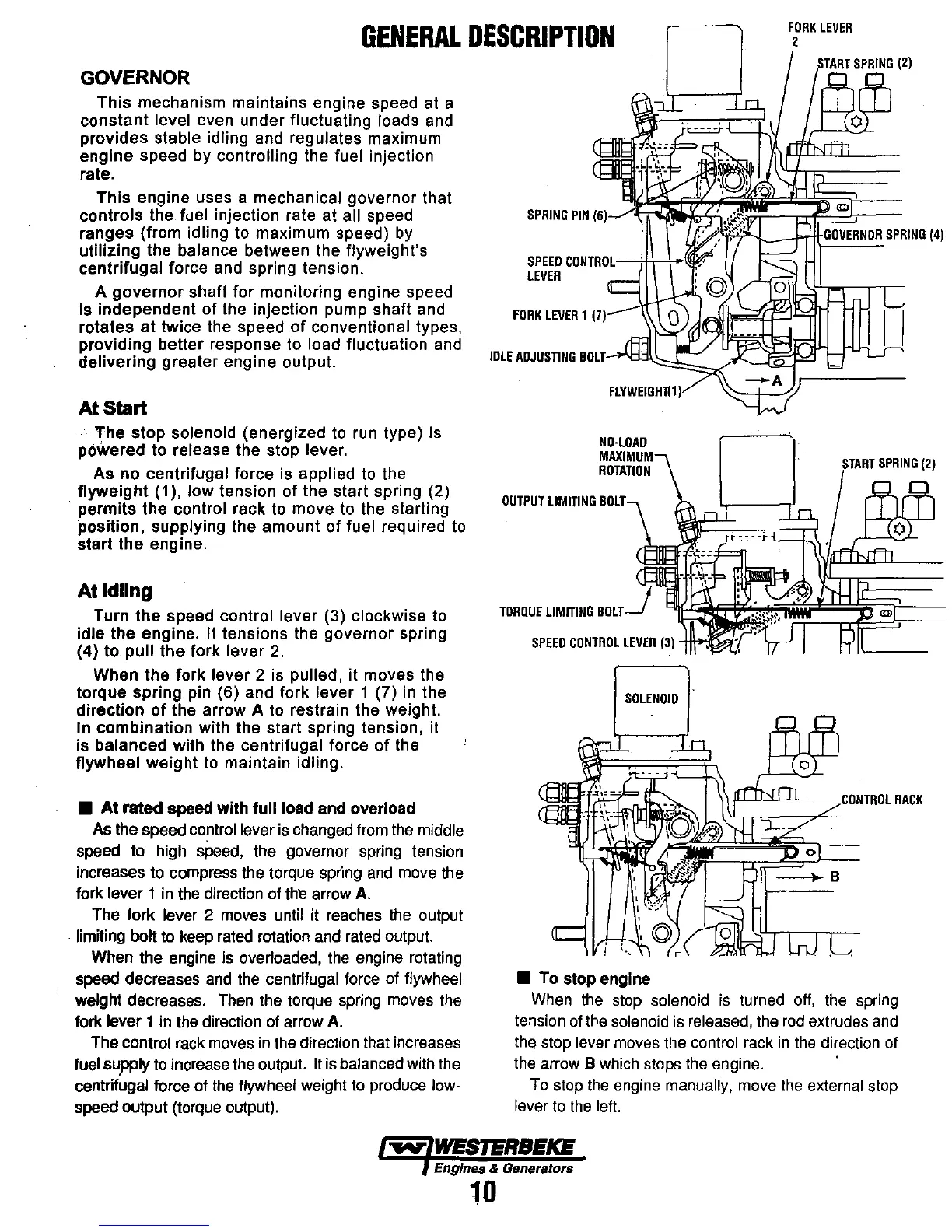

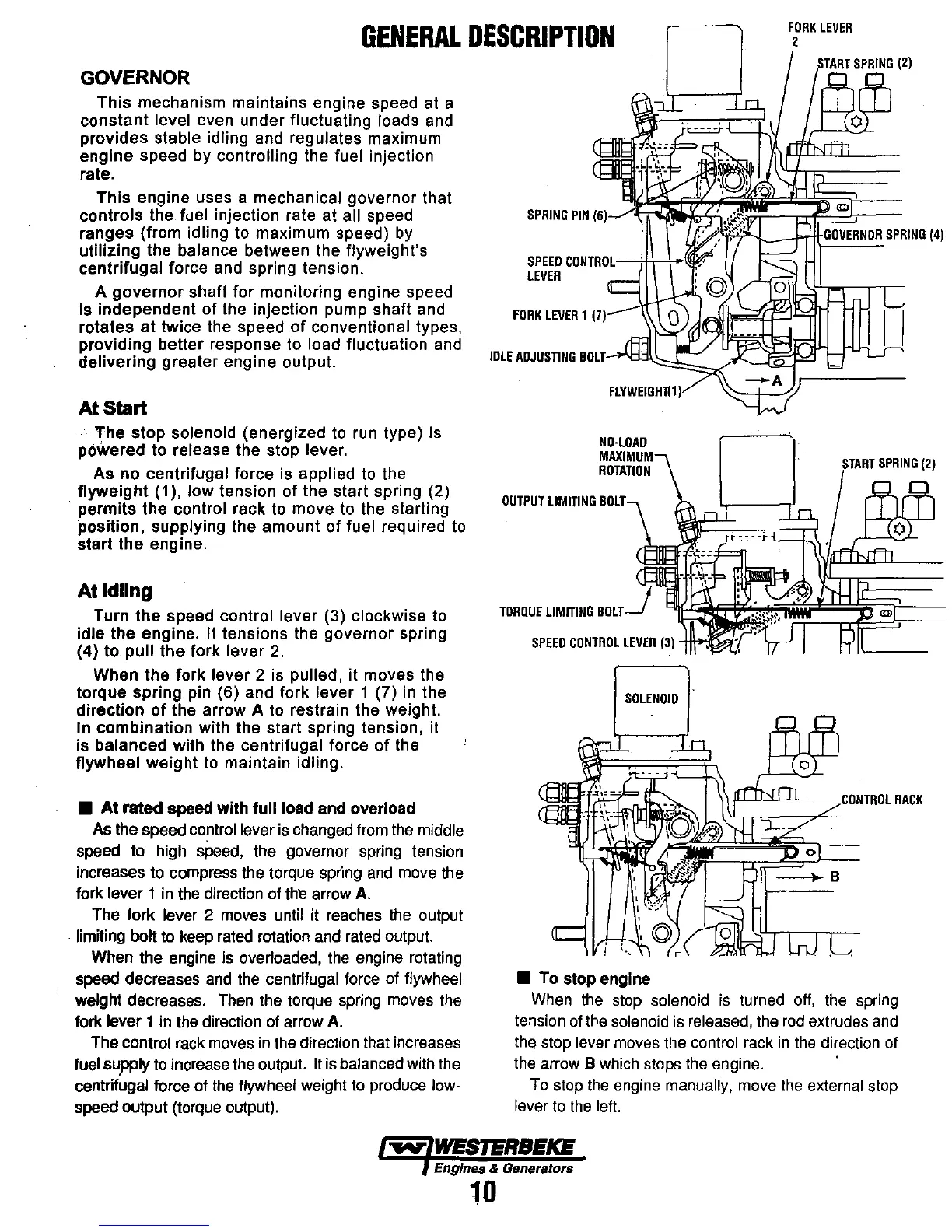

GOVERNOR

This

mechanism maintains engine speed at a

constant

level even under fluctuating loads and

provides

stable idling and regulates maximum

engine speed by

controlling the fuel injection

rate.

This

engine uses a mechanical governor that

controls the fuel injection rate at all speed

ranges (from

idling to maximum speed)

by

utilizing the balance between the flyweight's

centrifugal

force and spring tension.

A

governor

shaft for monitoring engine speed

is independent

of

the injection pump shaft and

rotates

at

twice the speed

of

conventional types,

providing better response to

load fluctuation and

delivering greater engine output.

At

Start

The

stop

solenoid (energized to run type) is

powered to

release the stop lever.

As no centrifugal force is applied to the

flyweight

(1), low tension

of

the start spring (2)

. permits the control rack to move to the starting

position,

supplying the amount

of

fuel required to

start

the

engine.

At

Idling

Turn

the

speed control lever (3) clockwise to

idle the engine. It tensions the governor spring

(4) to

pull

the

fork lever

2.

When the fork lever 2 is pulled, it moves the

torque spring pin (6) and fork

lever 1 (7)

in

the

direction

of

the arrow A to restrain the weight.

In combination with the start spring tension, it

is

balanced with the centrifugal force

of

the

flywheel

weight

to maintain idling.

• At rated speed with full load and overload

As

the speed control lever

is

changed

from

the

middle

speed to high

speed,

the governor spring tension

increases to compress the torque spring

and

move

the

fork lever 1

in

the

direction

of

the

arrow

A.

The fork lever 2

moves

until it

reaches

the

output

limiting bolt

to

keep

rated

rotation

and

rated

output.

When the engine

is

overloaded,

the

engine rotating

speed decreases

and

the

centrifugal force of flywheel

weight decreases.

Then

the torque

spring

moves

the

fork lever 1

in

the

direction

of

arrow

A.

The control

rack

moves

in

the

direction that increases

fuel supply

to

increase

the

output.

It

is

balanced with the

centrifugal force of

the

flywheel weight

to

produce low-

speed output (torque output).

SPRING

PIN

(6)';~~~~Q\;;;;~-.T'J'!:="'5---

SPEEO

CONTROL--ttt+~r

LEVER

FORK

LEVER

1

(7)

IDLE

ADJUSTING

BOLT-'Oll~::h;",,<

FLYWEIGH1l1

)

NO·LOAD

ROTATION

OUTPUT

LIMITING

BOLT

TORQUE

LIMITING

BOLT

SPEEO

CONTROL

LEVER

131-H\+l

• To stop engine

GOVERNOR

SPRING

(4)

/ll-l.l..>..w.J--

CONTROL

RACK

When

the

stop

solenoid

is

turned

off,

the

spring

tension

of

the

solenoid

is

released,

the

rod

extrudes

and

the stop lever

moves

the control

rack

in

the

direction

of

the

arrow B

which

stops

the

engine.

To

stop

the

engine

manually,

move

the

external stop

lever

to

the

left.

'9Y'

WESTERBEKE

Engines & Generators

10

Loading...

Loading...