TESTING

FOR

OVERHAUL

HOW

TO

DETERMINE

ENGINE

OVERHAUL

PERIOD

.

Cause

of

Low

Compression

Generally, the time at which

an

engine should be overhauled

is determined

by

various conditions such

as

lowered engine

power output, decreased compression pressure,

and

increased

fuel

and

oil

consumption. The lowered engine power output

is not necessarily due

to

trouble with the engine itself, but

is

sometimes caused

by

injector nozzle wear or injection pump

wear.

The decrease in compression pressure

is

caused

by

many

factors. It is, therefore, necessary

to

determine a cause

or causes

on

the

basis

of

data produced

by

periodic

inspection and maintenance.

Oil analysis on a seasonal basis

is a good means of monitoring engine internal

wear.

When

caused

by

worn

cylinders or piston rings,

the

following

symptoms will occur:

1 Low engine power output

2 Increased fuel consumption

3 Increased oil consumption

4

Hard

engine starting

5 Noisy engine operation

These symptoms often appear together. Symptoms 2

and

4

can result also from excessive fuel injection, improper

injection timing,

and

wear

of

the injectors. They are caused

also by defective electrical devices such

as

the battery,

alternator, starter

and

glow plugs. Therefore it is desirable

to

judge the optimum engine overhaul time

by

the

lowered

compression pressure caused

by

worn cylinders and pistons

plus increased oil consumption. Satisfactory combustion is

obtained only under sufficient compression pressure. If

an

engine lacks compression pressure, incomplete combustion

of fuel will take place even

if

other parts of the engine are

operating properly.

To

determine

the

period of engine

overhaul,

it

is

important

to

measure the engine compression

pressure regularly. At the same time,

the

engine speed

at

which the measurement

of

compression pressure

is

made

should be checked because the compression pressure varies

with engine rpm. The engine rpm

can

be measured at the

front end of the crankshaft.

OVERHAUL

CONDITIONS

Compression pressure tends

to

increase a little

in

a

new

engine until piston rings and valve seats have been broken

in.

Thereafter, it decreases gradually with the progress of wear

of these parts.

When decrease

of

compression pressure reaches the repair

limit, the engine must

be

overhauled.

The engine requires overhaul when oil consumption

is

high,

blowby evident, and compression valves are

at

minimum or

below.

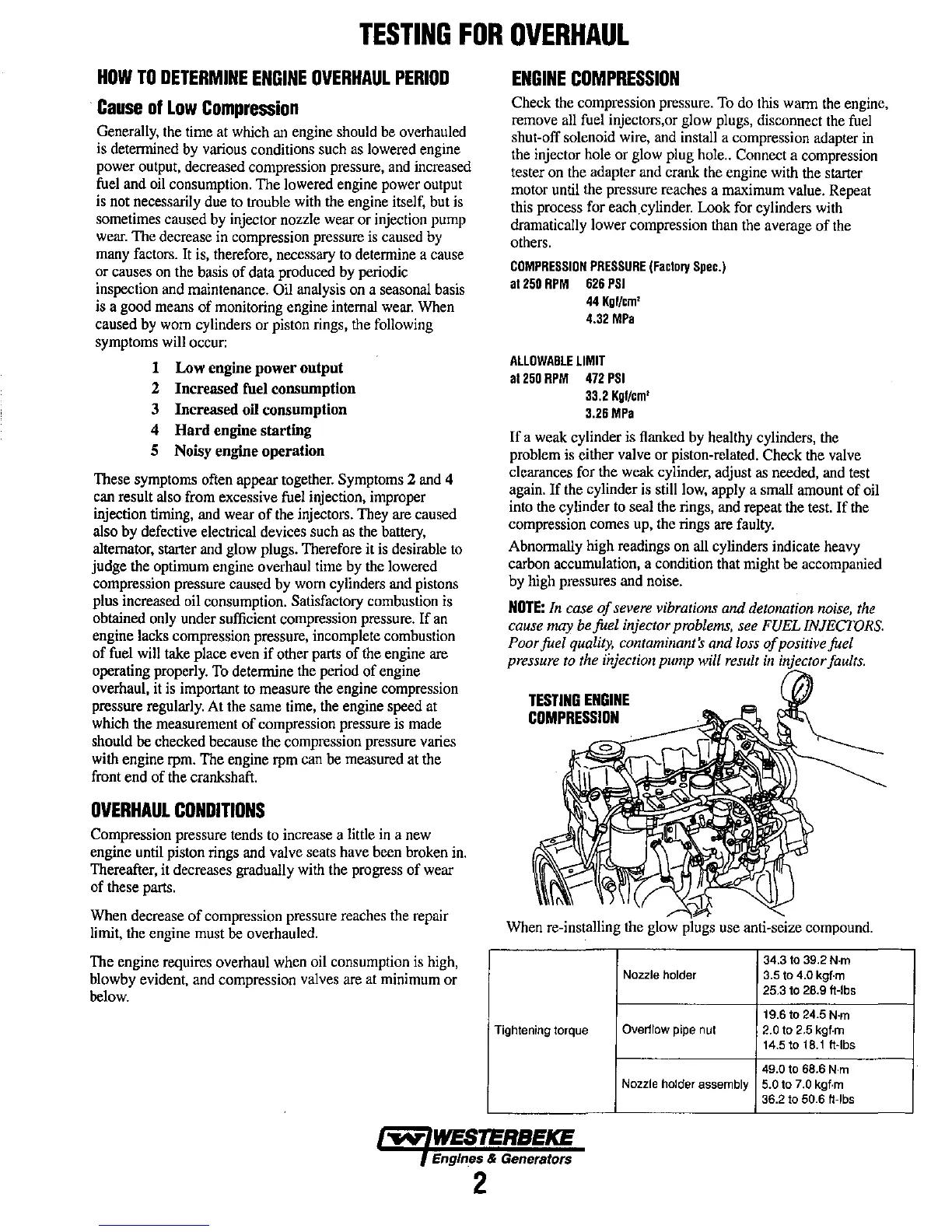

ENGINE

COMPRESSION

Check the compression pressure.

To

do

this warm

the

engine,

remove all fuel injectors,or glow plugs, disconnect the

fuel

shut-off solenoid wire,

and

install a compression adapter

in

the injector hole or glow plug hole

..

Connect a compression

tester on the adapter

and

crank the engine with

the

starter

motor until the pressure reaches a maximum value. Repeat

this process for

each

cylinder. Look for cylinders

with

dramatically lower compression than the average of

the

others.

COMPRESSION

PRESSURE

(Faclary

Spec.)

at

250

RPM

626

PSI

44

Kgl/cm'

4.32

MPa

ALLOWABLE

LIMIT

al250

RPM

472

PSI

33.2

Kgl/cm'

3.26

MPa

If

a weak cylinder is flanked

by

healthy cylinders, the

problem

is

either valve or piston-related. Check the valve

elearances for the weak cylinder, adjust

as

needed, and test

again.

If

the cylinder

is

still

low,

apply a small amount of

oil

into the cylinder

to

seal the rings, and repeat the test. If

the

compression comes up, the rings are

faulty.

Abnormally high readings on all cylinders indicate heavy

carbon accumulation, a condition that might be accompanied

by high pressures and noise.

NOTE:

In case

of

severe vibrations and detonation noise, the

cause may be fuel injector problems, see

FUEL INJECTORS.

Poor

fuel quality, contaminants and loss

of

po

sitive fuel

pressure to the injection pump will result

in

faults.

TESTING

ENGINE

COMPRESSION

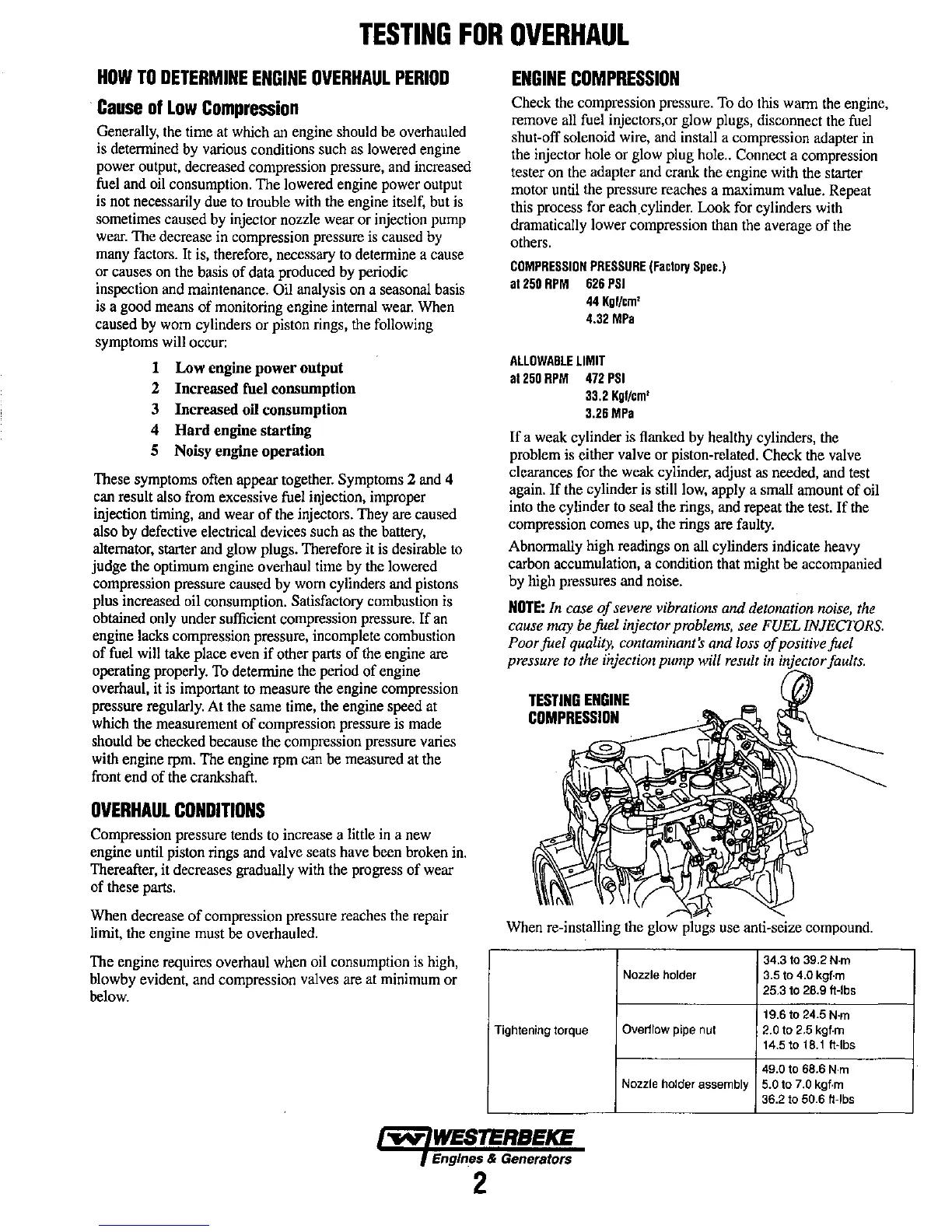

When re-installing the glow use anti-seize compound.

34.3

to

39.2

N·m

Nozzle holder

3.5

to

4.0

kgf·m

25.3

to

2B.9

ft-Ibs

t9.6

to

24.5

N·m

Tightening torque

Over1low pipe nut

2.0

to

2.5

kgf·m

14.5

to

tB.t

ft·lbs

49.0

to

6B.6

N·m

Nozzle holder assembly

5.0

to

7.0

kgl·m

36.2

to

50.6

ft·lbs

Engines & Generators

2

Loading...

Loading...