FUEL

SYSTEM

GLOW

FLUGS

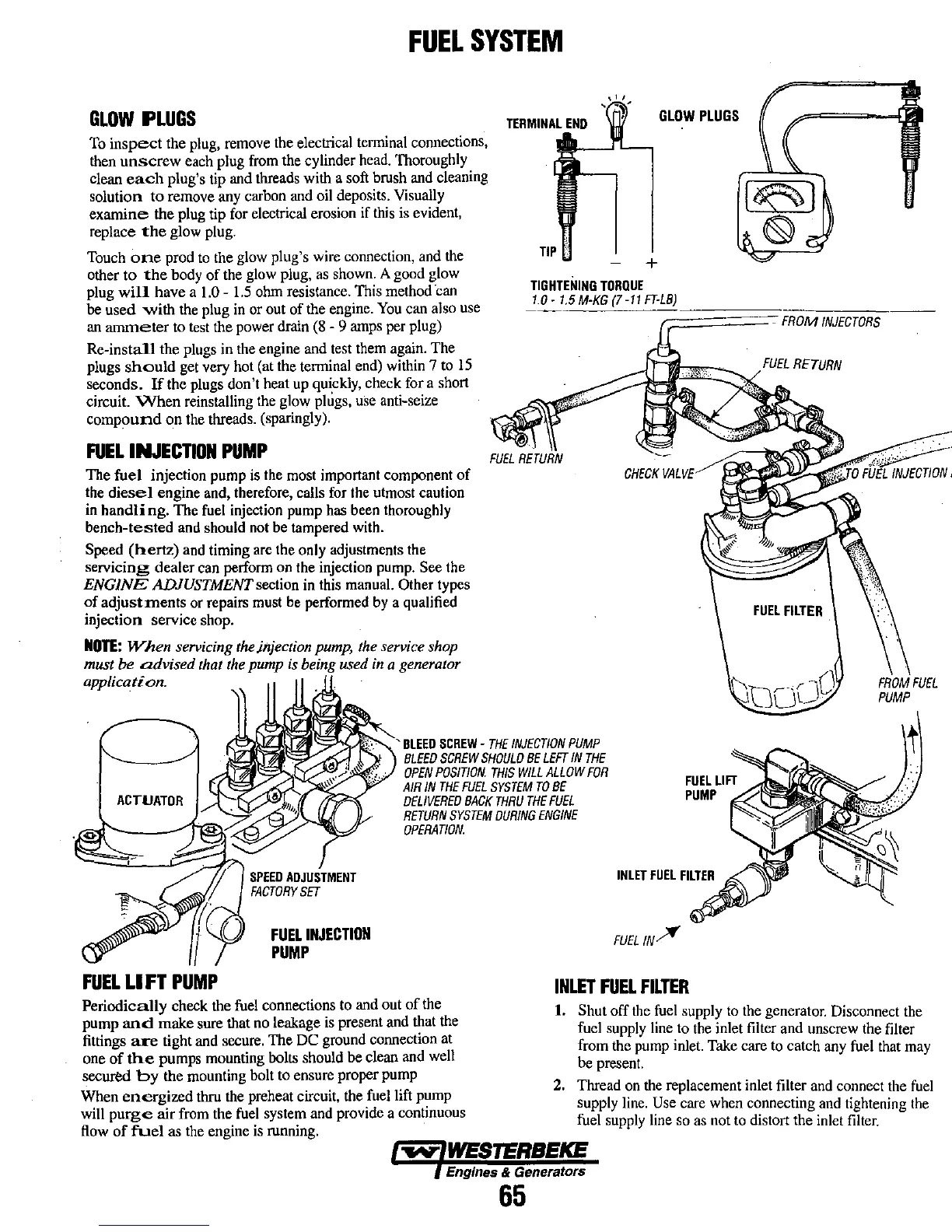

GLOW

PLUGS

To

inspect

the plug, remove the electrical terminal connections,

then

unscrew

each plug from the cylinder head. Thoroughly

clean

each

plug's tip and threads with a soft brush and cleaning

solution

to

remove any carbon and oil deposits. Visually

examine

the plug tip for electrical erosion if this is evident,

replace

the

glow plug.

TIP'

+

Touch

one

prod

to

the glow plug's wire connection, and the

other

to

the

body

of

the glow plug, as shown. A good glow

plug

will

have a 1.0 -

1.5

ohm resistance. This method 'can

TIGHTENING

TORQUE

be

used

with

the plug in or out

of

the engine.

You

can also use

an

ammeter

to test the power drain

(8

- 9 amps per plug)

1.0

-

1.5

M-KG

(7

-11

Fr-LB)

Re-install

the plugs

in

the engine and test them again. The

plugs

should

get very hot (at the terminal end) within 7 to

15

seconds_

If

the plugs don't heat up quickly, check for a short

circuit.

When

reinstalling the glow phigs, use anti-seize

compound

on

the threads. (sparingly).

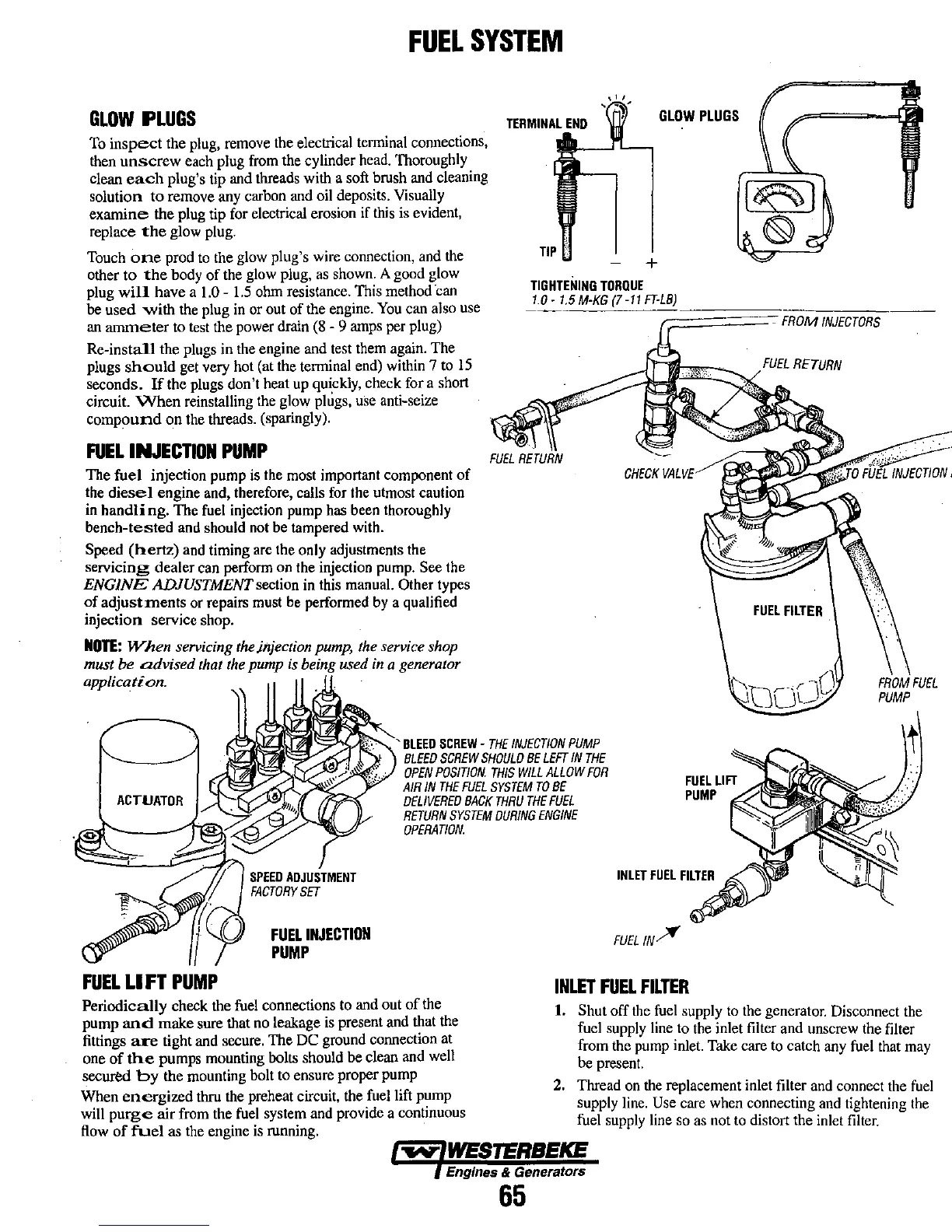

FUEL

INJECTION

PUMP

The

fuel

injection pump is the most important component

of

the

diesel

engine

and,

therefore,

calls

for

the

utmost

caution

in

handli

ng.

The fuel injection pump has been thoroughly

bench-tested

and should not be tampered with.

Speed

(hertz)

and timing are the only adjustments the

servicing

dealer can perform on the injection pump. See the

ENGINE

ADJUSTMENT section in this manual. Other types

of

adjustments

or repairs must be performed by a qualified

injection service shop.

NOn:

When

servicing

the

jnjection pump, the service shop

must

be

advised

that the pump

is

being used

in

a generator

application.

FUEL

RETURN

ACTUATOR

.

<>

,

BLEED

SCREW

-

THE

INJECTION

PUMP

BLEEO

SCREW

SHOULD

BE

LEFr

IN

THE

OPEN

POSITION.

mls

WILL

ALLOW

FOR

AIR

IN

THE

FUEL

SYSTEM

TO

BE

DELIVERED

BACK

THRU

THE

FUEL

RETURN

SYSTEM

DURING

ENGINE

OPERATION

.

,-

FUEL

INJECTION

PUMP

FUELIN~

FUEL

LI

FT

PUMP

INLET

FUEL

FILTER

----

FROM

INJECTORS

FUEL

RETURN

FUEL

FILTER

Periodically

check the fuel connections to and out

of

the

pump

and

make

sure that no leakage is present and that the

fittings

are

tight and secure. The

DC

ground connecl1on at

one

of

the

pumps mounting bolts should be clean and well

secured

by

the mounting bolt to ensure proper pump

1_

Shut off the fuel supply

to

the generator. Disconnect the

fuel supply line to the inlet filter and unscrew the filter

from the pump inlet. Take care to catch any fuel that may

be present.

When

energized

thru the preheat circuit, the fuel lift pump

will

purge

air

from the fuel system and provide a continuous

flow

of

fuel

as the engine is running.

2. Thread on the replacement inlet filter and connect the fuel

supply line.

Use care when connecting and tightening the

fuel supply line so as not to distort the inlet filter.

...v-

WESTERBEKE

Engines & Generators

65

Loading...

Loading...