Flywheel and Crankshaft

Flywheel

DISASSEMBLY

I

ASSEMBLY

1.

Install the flywheel lock

so

that the flywheel does

not turn .

•

NOTE

•

Do

not

use an impact wench. Serious damage will occur.

2. Detach

the

flywheel

screws.

3. Remove the flywheel.

(When reassembling)

• Apply ergine

oil

to

the

flywheel

screws.

• Before fitting the flywheel

and

the

crankshaft together, wipe

oil, dust and other foreign substances

off

their

mating

faces.

• The flywheel

and

the

crankshaft

are

fitting together

in

just

one

position. Make sure they

are

tightly fit

and

drive

the

bolts.

Tightening torque

Flywheel

screw

Bearing Case Cover

•

NOTE

98.110 107.9

N·m

10.0 to 1 t

.0

kgf·m

72.3 to 79.6 «-Ibs

• Before disassembling, check the side clearance

of

crankshaft. Also check

it

during reassembly.

1.

Remove the bearing

case

over

mounting screws.

2.

Screw two removed screws into

the

screw

hole

(3)

of

bearing

case cover

to

remove

it.

(When reassembling)

•

IMPORTANT

• In case

of

replacing the oil seal, use caution when

installing

the seal in the bearing case cover as not to

install

it

tilted. The seal should

be

flush with the cover.

• Confirm that the liquid gasket coating surface is free

of

water,

dust

and oil

in

order to maintain sealing effect.

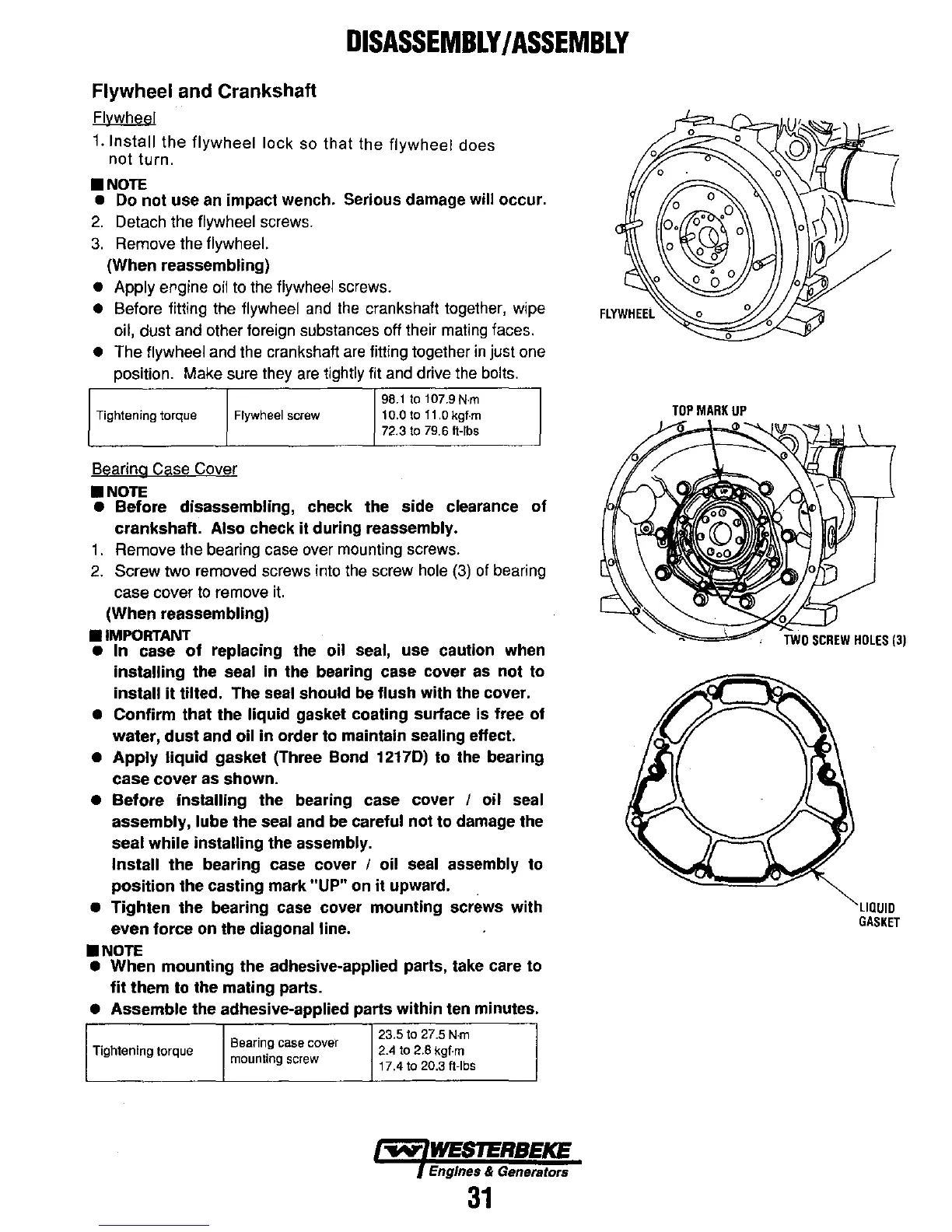

•

Apply

liquid gasket (Three Bond 12170) to the bearing

case cover as shown.

• Before installing the bearing case cover I

oil

seal

assembly,

lube the seal and be careful not to damage the

seal while installing the assembly.

Install

the bearing case cover I oil seal assembly to

position

the casting mark "UP" on

it

upward.

• Tighten the bearing case cover mounting screws with

even force on the diagonal

line .

•

NOTE

• When mounting the adhesive-applied parts, take care to

fit

them to the mating parts.

• Assemble the adhesive-applied parts within ten minutes.

Bearing

case

cove'r

23.5 to 27.5

N·m

Tightening torque

2.4 to 2.8 kgf·m

mounting

screw

17.4 to 20.3 «-Ibs

Engines & Generators

31

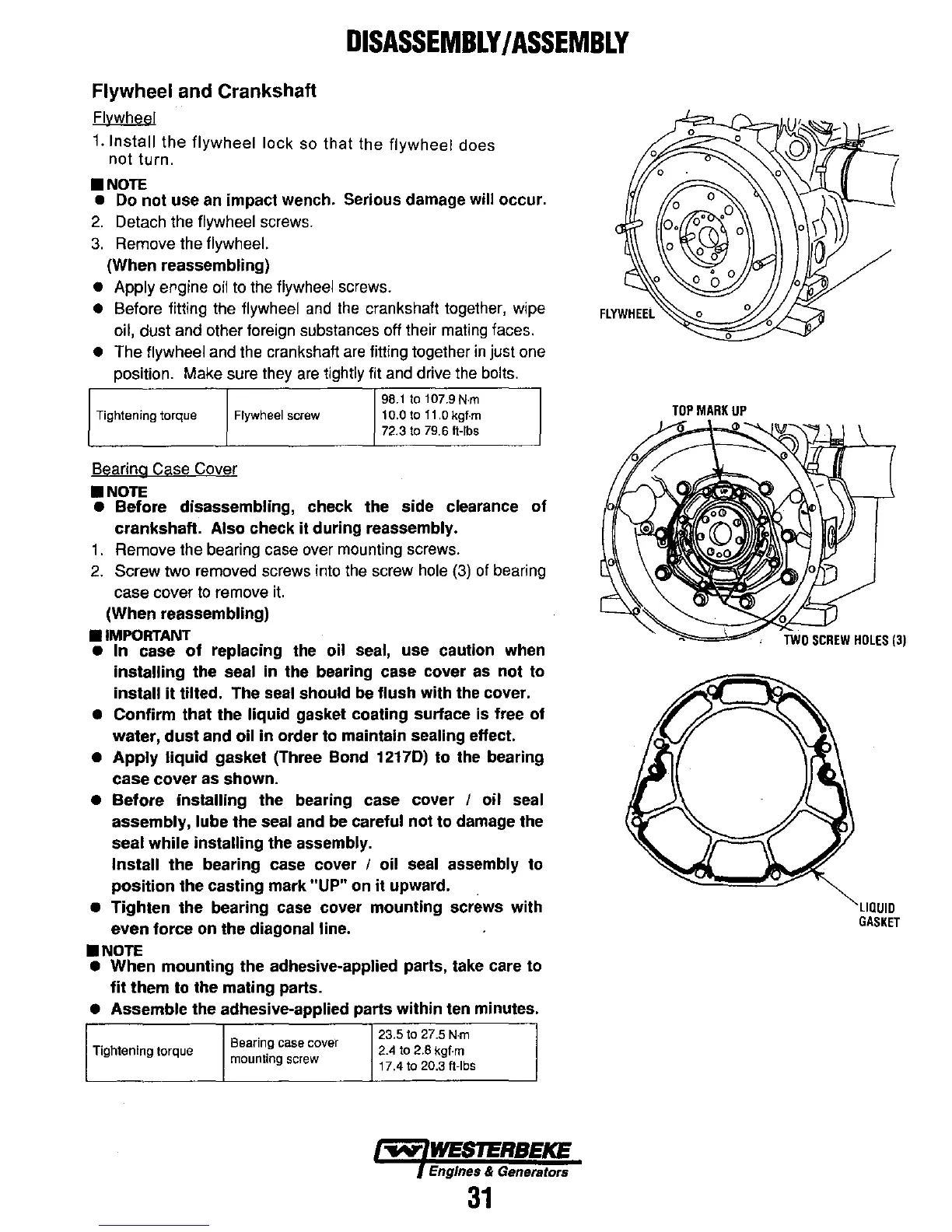

TOP

MARK

UP

TWO

SCREW

HOLES

(3)

LIQUID

GASKET

Loading...

Loading...