SERVICING

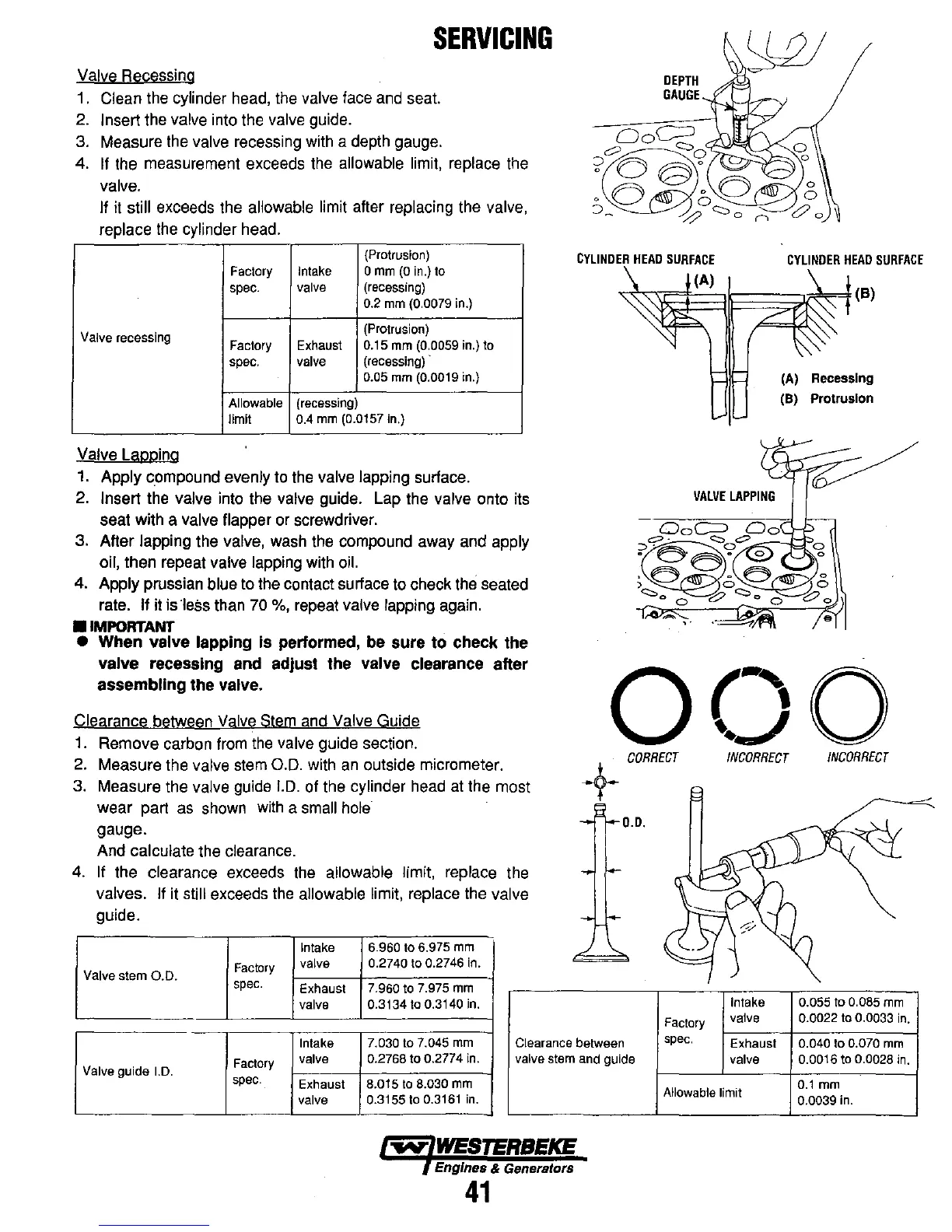

Valve Recessing

1.

Clean the cylinder head, the valve face and

seat

2. Insert the valve into the valve guide.

3.

Measure the valve recessing with a depth gauge.

4.

If the measurement exceeds the allowable limit, replace the

valve.

If

it still exceeds the allowable limit after replacing the valve,

replace the

cylinder head.

(Protrusion)

Factory Intake o mm (0 in.)

to

spec. valve (recessing)

0.2

mm

(0.0079 in.)

Valve recessing

(Protrusion)

Factory Exhaust

0.'5

mm

(0.0059 in.)

to

spec. valve

(recessing)

,

0.05

mm

(0.00t9

in.)

Allowable (recessing)

limit

0.4 mm (0.0157 in.)

Valve Lapping

1.

Apply compound evenly to the valve lapping surface.

2.

Insert the valve into the valve guide. Lap the valve onto its

seat with a

valve flapper or screwdriver.

3.

After lapping the valve, wash the compound away and apply

oil, then repeat valve lapping with oil.

4. Apply prussian blue to the contact surface to check the seated

rate.

If it is 'Iess than

70

%, repeat valve lapping again.

•

IMPORTANT

• When valve lapping is performed, be sure to check the

valve recessing and adjust the valve clearance after

assembling the valve.

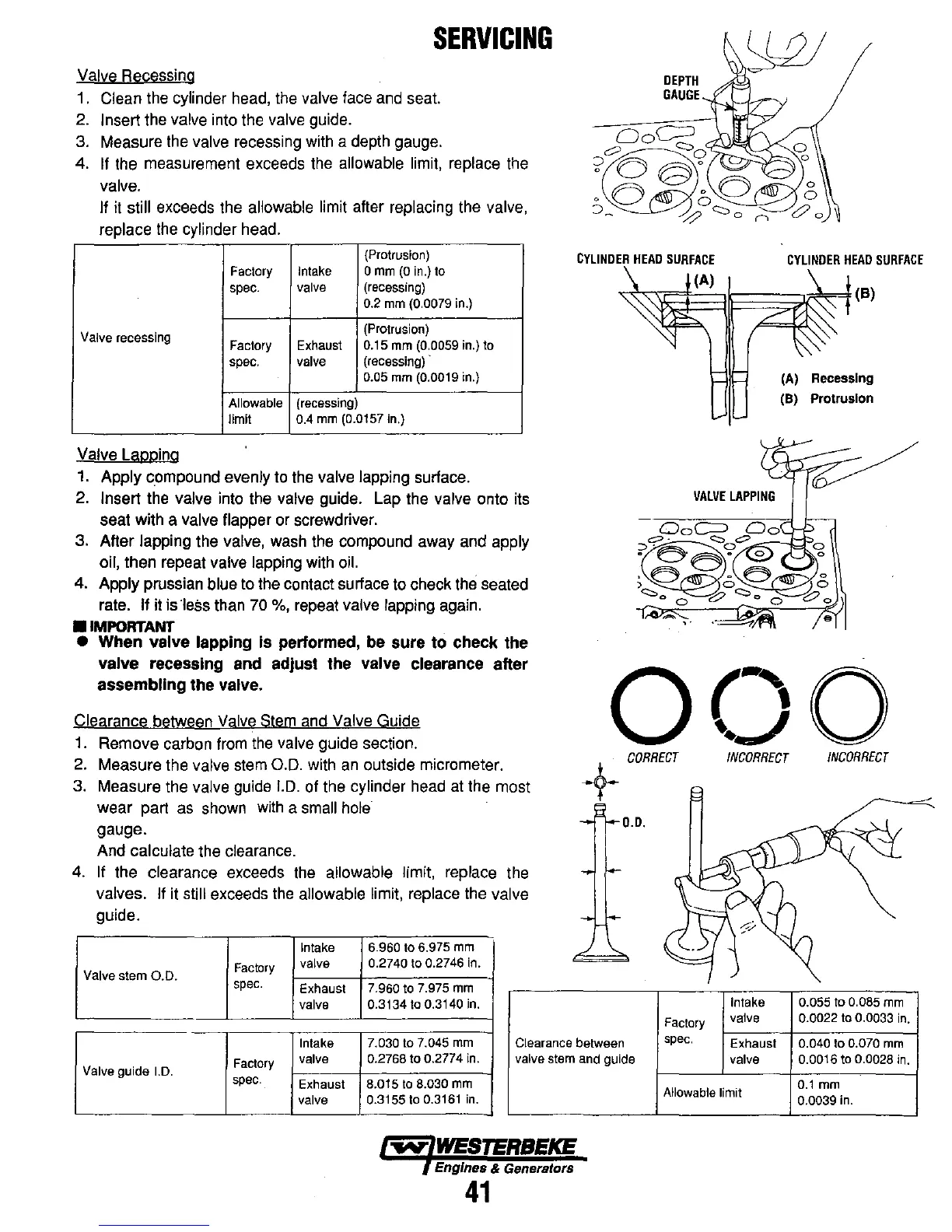

Clearance between Valve Stem and Valve Guide

1.

Remove carbon from

the

valve guide section.

2.

Measure the valve stem

0.0.

with an outside micrometer.

3.

Measure the valve guide 1.0. of the cylinder head

at

the most

wear part

as

shown

with

a small hole

gauge.

And

calculate the clearance.

4.

If the clearance exceeds the allowable limit, replace the

valves.

If it still exceeds the allowable limit, replace the valve

guide.

Intake

6.960

to

6.975

mm

Factory

valve

0.2740

to

0.2746 in.

Valve stem

0.0.

spec.

Exhaust

7.960

to

7.975 mm

valve

0.3134

to 0.3140 in.

DEPTH

GAUGE

,*-.l-U))

CYLINDER

HEAD

SURFACE

CYLINDER

HEAD

SURFACE

~~~(A~)~~~~\~i

(8)

0

+

CORRECT

D.D.

Factory

(A) Recessing

(8)

Protrusion

..

(

.....

,

~.J

0

INCORRECT

INCORRECT

Intake

0.055

to

0.085 mm

valve

0.0022

to

0.0033 in.

Intake

7.030

to

7.045 mm

Clearance between

spec.

Exhaust

0.040

to

0.070 mm

Factory

valve

0.2768

to

0.2774 in.

Valve guide

1.0.

spec.

Exhaust

8.015

to 8.030 mm

valve

0.3155 to 0.3161 in.

valve stem

and

guide

valve

0.0016

to

0.0028 in.

Allowable limit

0.1

mm

0.0039 in.

Engines & Generators

41

Loading...

Loading...